Tunable full medium multi-frequency band isotrope zero-refraction flat-plate lens and preparation thereof

An isotropic, flat lens technology, applied in the directions of waveguides, circuits, electrical components, etc., can solve the problems of limited application range, difficult to zero refraction effect, limited practical application, etc., to achieve the effect of improving directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

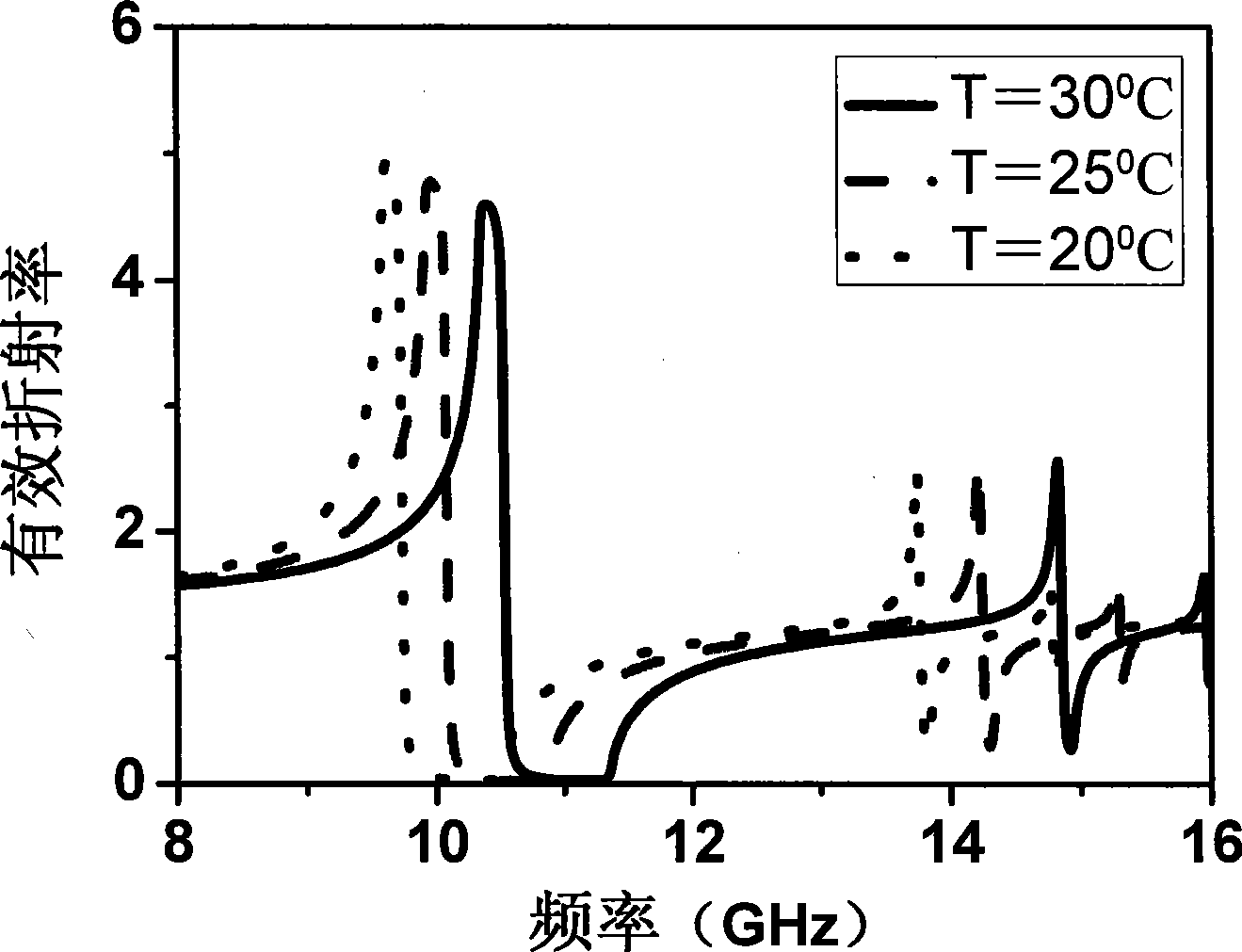

[0030] Ba with a mass ratio of 20:3 0.5 Sr 0.5 TiO 3Mix with MgO powder and a certain amount of alcohol and put it into a ball mill jar for ball milling for 24 hours, then dry the alcohol in an oven at 60°C to obtain a uniformly mixed medium powder; mix the medium powder with 5wt% polyvinyl alcohol resin Uniformly mixed and granulated and pressed into a columnar rough body by isostatic pressing; the rough body was degummed in an electric furnace at 300-600°C, and then sintered at 1400°C for 3 hours to obtain a dense columnar ceramic block ; Cut the ceramic column into a dielectric cube 1 with a side length of 1.75mm by using laser ceramic micromachining technology, and its microwave dielectric constant is 195 at a room temperature of 25°C.

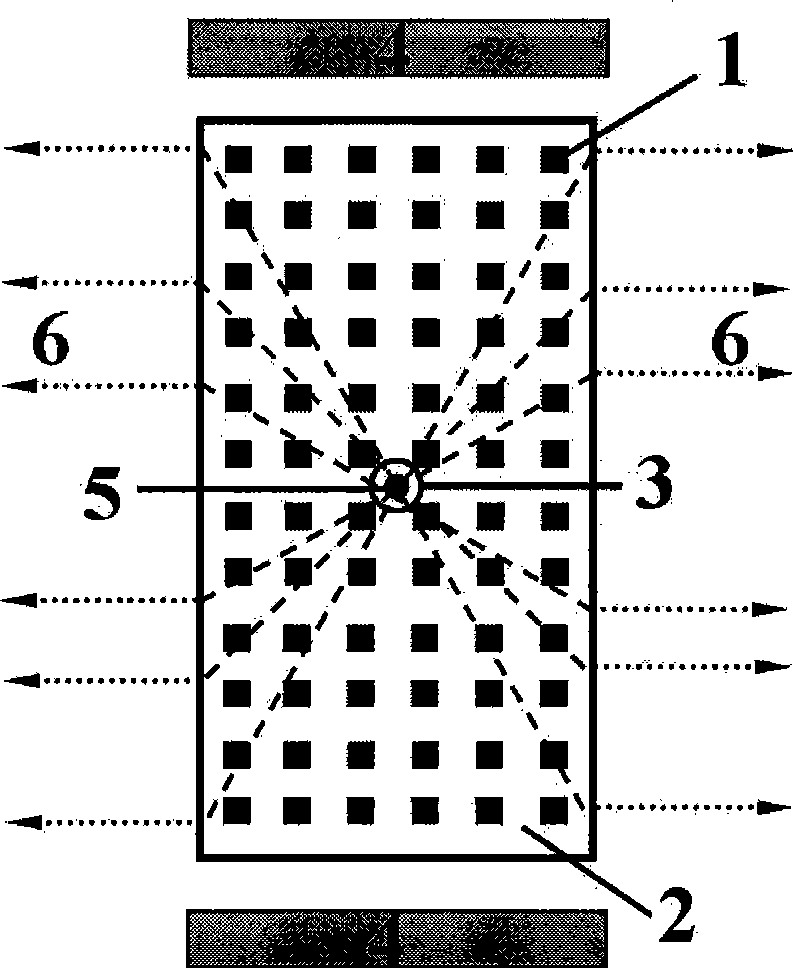

[0031] Arrange the dielectric cubes into a simple cubic lattice with a lattice constant of 3.0 mm, and the volume fraction is 30%, and use epoxy resin 2 to cure the periodic lattice structure to obtain a composite of dielectric particles...

Embodiment 2

[0035] With embodiment one, the Ba that mass ratio is 9:1 0.5 Sr 0.5 TiO 3 Ball milling with MgO powder and using isostatic pressing forming technology to form a columnar blank body; debinding the blank body in an electric furnace and sintering it to a dense columnar ceramic block at 1400 ° C; using laser ceramic micromachining technology to cut the ceramic column into The dielectric cube 1 with a side length of 0.5mm has a microwave dielectric constant of 350 at a room temperature of 25°C.

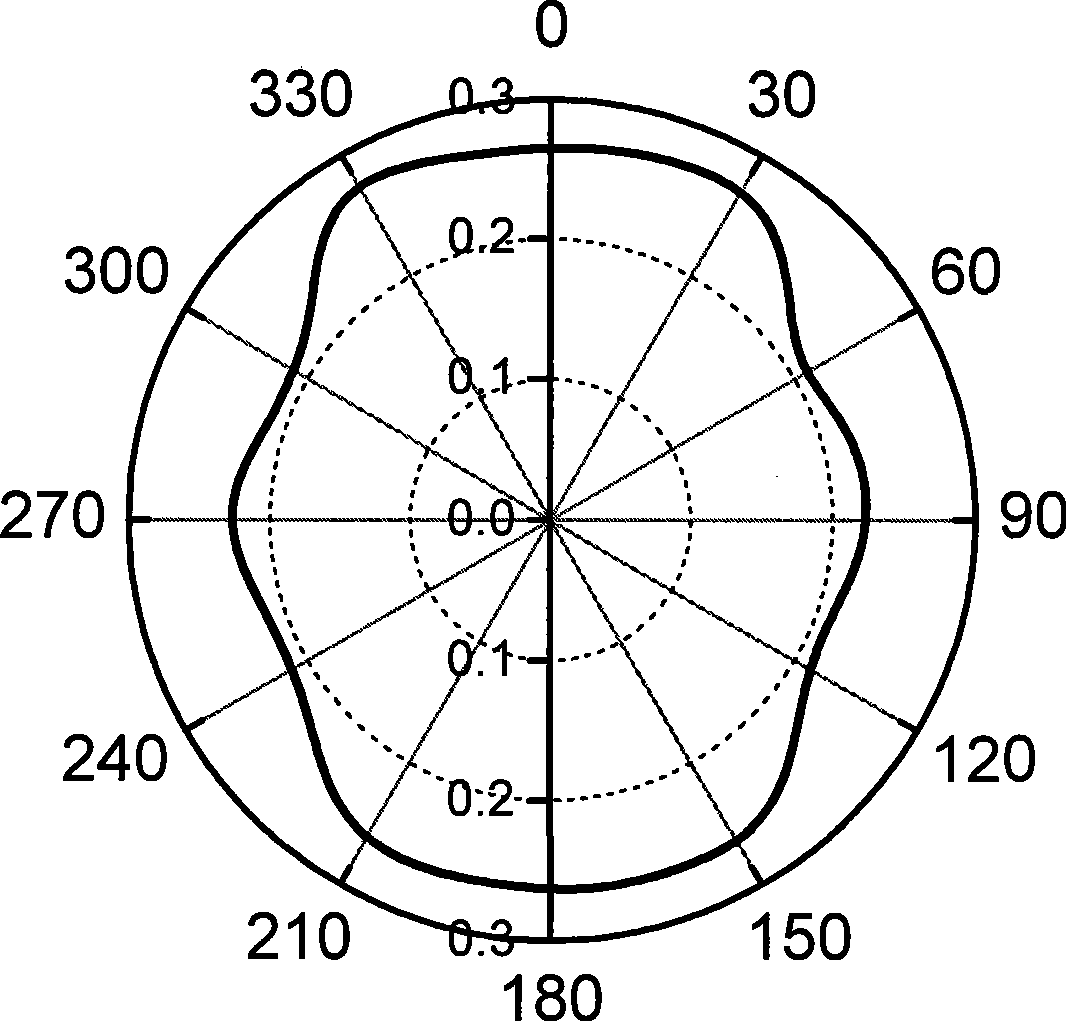

[0036] Arrange the dielectric cubes into a simple cubic lattice with a lattice constant of 1.0mm, and the volume fraction is 12.5%, and use epoxy resin 2 to cure the periodic lattice structure to obtain a composite of dielectric particles dispersed in epoxy resin material, and then cut the composite material into a flat plate shape; use a bench drill to punch a through hole 3 with a diameter of 3.0mm in the center of the flat lens, and place a monopole antenna 5 in the hole; finally, pl...

Embodiment 3

[0038] With embodiment one, Pb x Sr 1-x TiO 3 The powder is ball milled and pressed into a columnar rough body by isostatic pressing technology; the rough body is degummed in an electric furnace and sintered at 1300°C to a dense columnar ceramic block; the ceramic column is cut into side lengths by laser ceramic micromachining technology Dielectric cube 1 with a diameter of 3.0mm has a microwave dielectric constant of 450 at a room temperature of 25°C.

[0039] Arrange the dielectric cubes into a simple cubic lattice with a lattice constant of 8.0mm, and the volume fraction is 5%, and use epoxy resin 2 to cure the periodic lattice structure to obtain a composite of dielectric particles dispersed in epoxy resin material, and then cut the composite material into a flat plate shape; use a bench drill to punch a through hole 3 with a diameter of 3.0mm in the center of the flat lens, and place a monopole antenna 5 in the hole; finally, place the above-mentioned medium plate In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com