Congealing stone gelled material with ferro-silico-manganese alloy slag as principal raw material

A technology of silicon-manganese ferroalloy and cementitious materials, applied in the field of gelatinous cementitious materials, can solve problems such as polluted water sources, dust noise, social environment and ecological environment damage, and achieve excellent performance, environmental protection and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

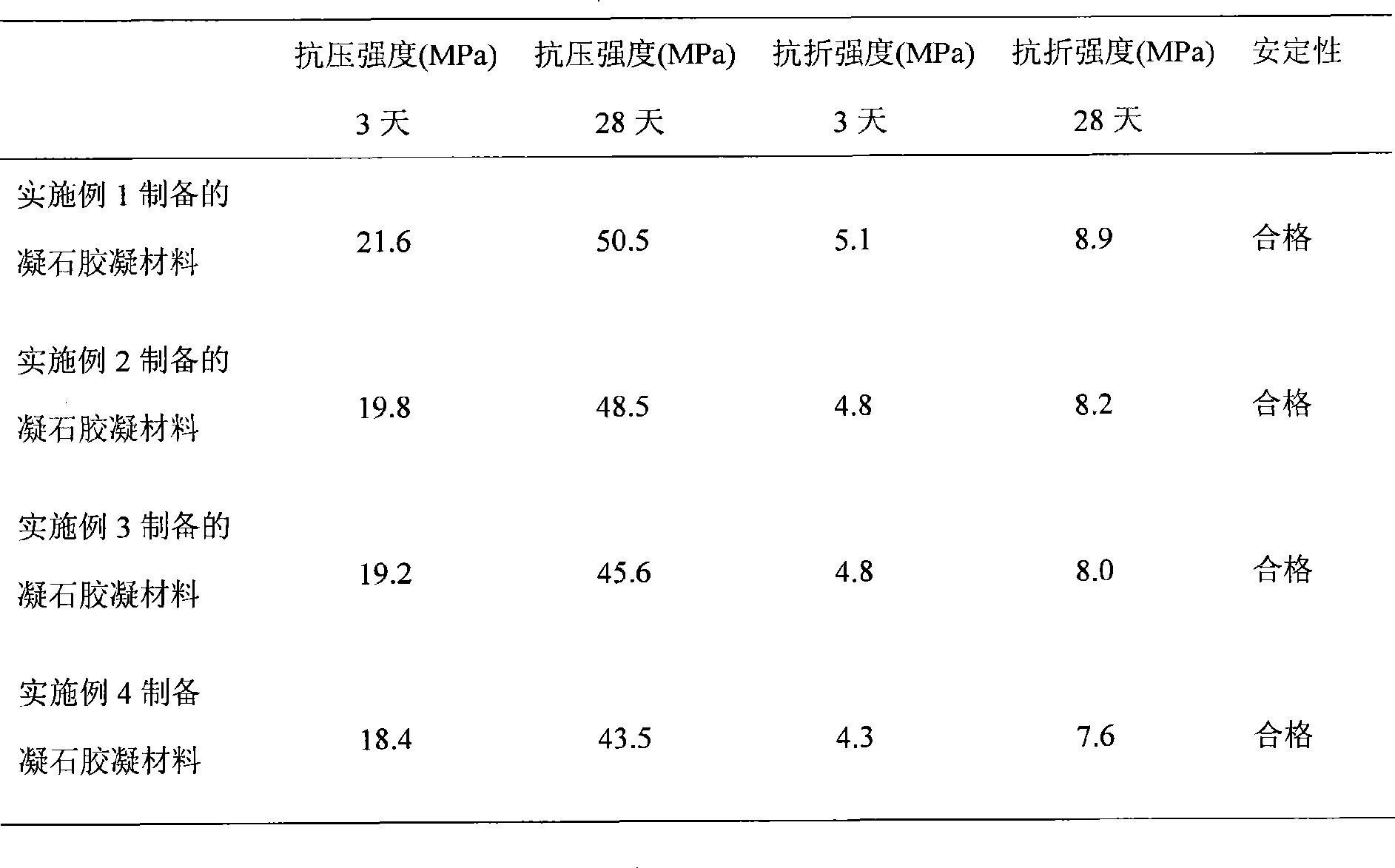

Examples

Embodiment 1

[0020] A gelatinous cementitious material using ferrosilicomanganese alloy slag as the main raw material, the gelatinous cementitious material uses ferrosilicon-manganese alloy slag, cement clinker, gypsum, coal burning waste residue and diagenetic agent as raw materials, and the content by weight percentage For, silicomanganese ferroalloy slag: 60%, cement clinker: 15%, gypsum (the gypsum is natural anhydrite): 6%, coal combustion waste residue: 18%, diagenetic agent (the diagenetic agent is condensate A diagenetic agent): 1%.

[0021] The chemical composition of the ferrosilicon-manganese alloy slag is by weight percentage, Al 2 o 3 : 16.18%, SiO 2 : 39.12%, MgO: 14.53%, CaO: 29.32%, Fe 2 o 3 : 0.15%, MnO: 0.2%, Ignition substances: 0.5%.

[0022] The coal burning waste slag is circulating fluidized bed slag and fly ash, wherein, the weight percentage of circulating fluidized bed slag accounts for 10% of the gelatin cementitious material, and the weight percentage of fl...

Embodiment 2

[0027] A gelatinous cementitious material using ferrosilicomanganese alloy slag as the main raw material, the gelatinous cementitious material uses ferrosilicon-manganese alloy slag, cement clinker, gypsum, coal burning waste residue and diagenetic agent as raw materials, and the content by weight percentage For, silicomanganese ferroalloy slag: 68%, cement clinker: 15%, gypsum (the gypsum is dihydrate gypsum): 6%, coal burning waste residue: 10%, diagenetic agent (the diagenetic agent is diagenetic stone A agent): 1%.

[0028] The chemical composition of the ferrosilicon-manganese alloy slag is by weight percentage, Al 2 o 3 : 27.97%, SiO 2 : 29.87%, MgO: 3.59%, CaO: 27.65%, Fe 2 o 3 : 2.97%, MnO: 4.12%, Ignition substances: 3.83%.

[0029] The coal combustion waste slag is circulating fluidized bed slag.

[0030] The chemical composition of the circulating fluidized bed slag is in percentage by weight, Al 2 o 3 : 29.98%, SiO 2 : 29.97%, MgO: 6.92%, CaO: 13.21%, Fe ...

Embodiment 3

[0034] A gelatinous cementitious material with ferrosilicomanganese alloy slag as the main raw material. The gelatinous cementitious material uses ferrosilicomanganese alloy slag, gypsum, coal combustion waste residue and diagenetic agent as raw materials, and the content by weight is, silicomanganese Ferroalloy slag: 70%, gypsum (the gypsum is phosphogypsum): 8%, coal combustion waste residue: 19%, diagenetic agent (the diagenetic agent is condensate C diagenetic agent): 3%.

[0035] The chemical composition of the ferrosilicon-manganese alloy slag is by weight percentage, Al 2 o 3 : 26.96%, SiO 2 : 37.89%, MgO: 11.96%, CaO: 17.52%, Fe 2 o 3: 1.86%, MnO: 1.65%, Ignition substances: 2.16%.

[0036] The coal burning waste residue is fly ash and lightly burned coal gangue.

[0037] The weight percentage of the fly ash accounts for 9% of the gelatinous cementitious material, and the weight percentage of lightly burned coal gangue accounts for 10% of the gelatinous cementitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com