Continuous thin film vacuum deposition method and apparatus

A vacuum deposition and deposition device technology, applied in vacuum evaporation plating, gaseous chemical plating, ion implantation plating, etc., can solve the problems of substrate glass sheet pressure imbalance, glass sheet flutter, etc., and achieve continuous raw material utilization The effect of reducing the rate and spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

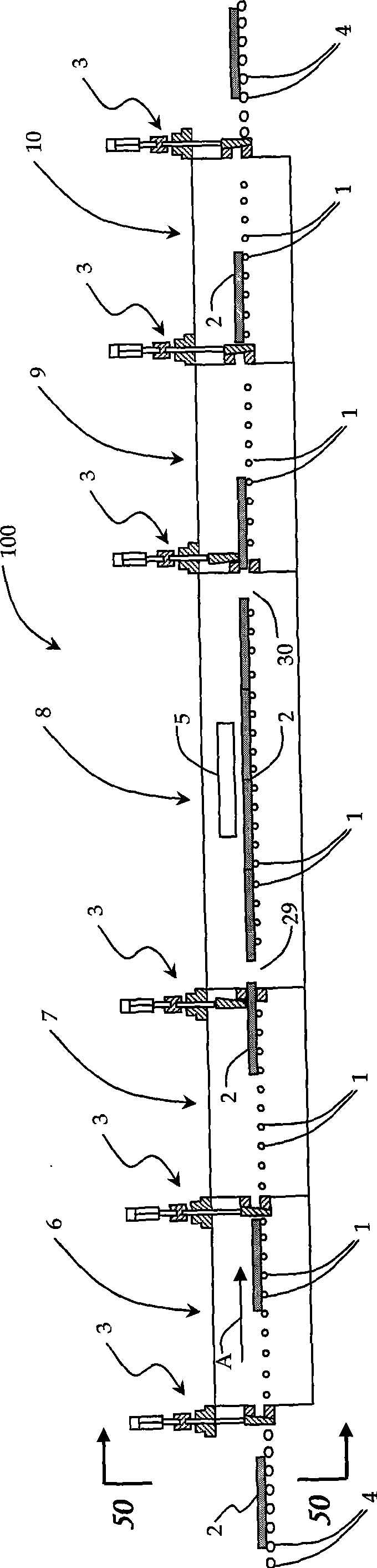

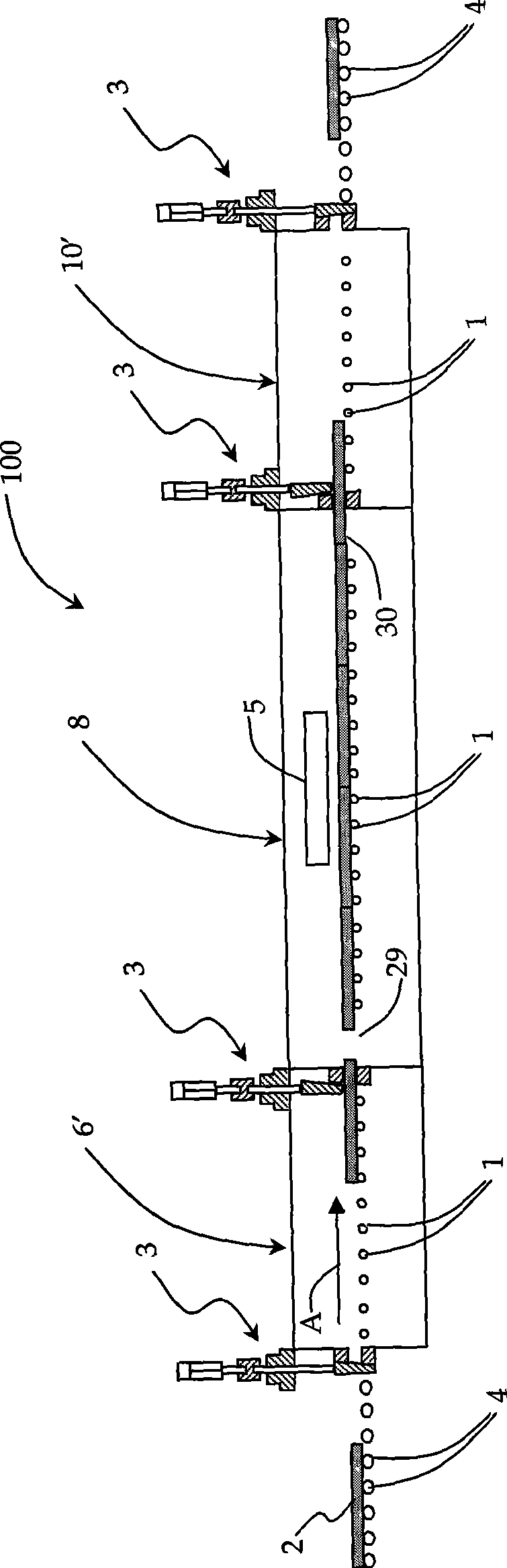

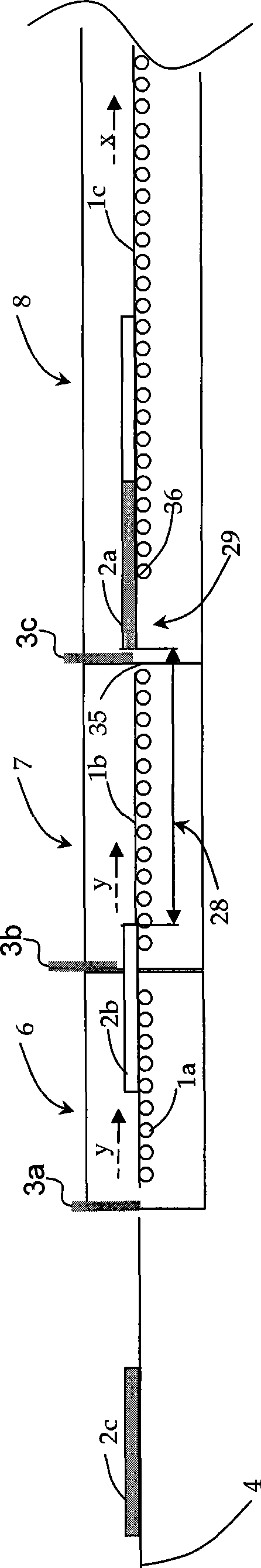

[0036]The invention includes a vacuum deposition chamber: used for depositing thin films on a substrate, equipped with a deposition device; at least one level of inlet vacuum pre-pumping chamber: connected with the inlet of the vacuum deposition chamber, equipped with a vacuum pump; at least one level of outlet vacuum protection chamber: connected with a vacuum The outlet of the deposition chamber is connected and equipped with a vacuum pump; the conveying device: equipped with a conveyor belt and a conveying wheel, which is used to continuously convey the substrate at a certain interval and a certain speed from the external atmosphere through the inlet vacuum pre-pumping chamber into the vacuum deposition chamber for deposition, and From the vacuum deposition chamber to the external atmosphere through the exit vacuum protection chamber, at least one level of inlet vacuum pre-pumping chamber is set at the entrance of the vacuum deposition chamber, and at least one level of exit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com