Integral united test apparatus of wind power generator

A technology for wind turbines and generators, applied in wind turbine components, wind turbines, wind turbine combinations, etc., can solve the problems of low reliability wind turbines, low reliability, slow debugging speed, etc., and achieve vibration Small, small moment of inertia, easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

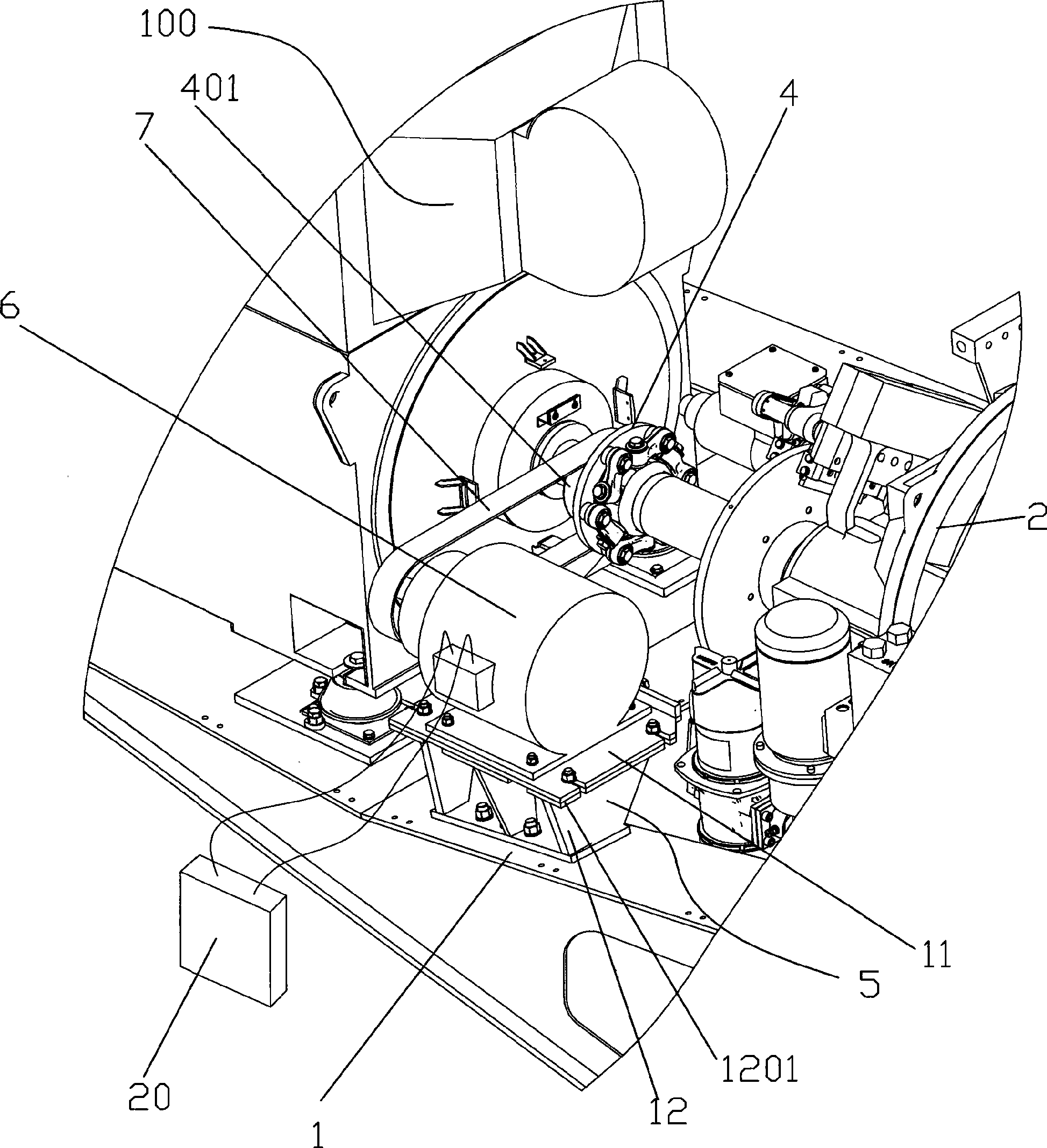

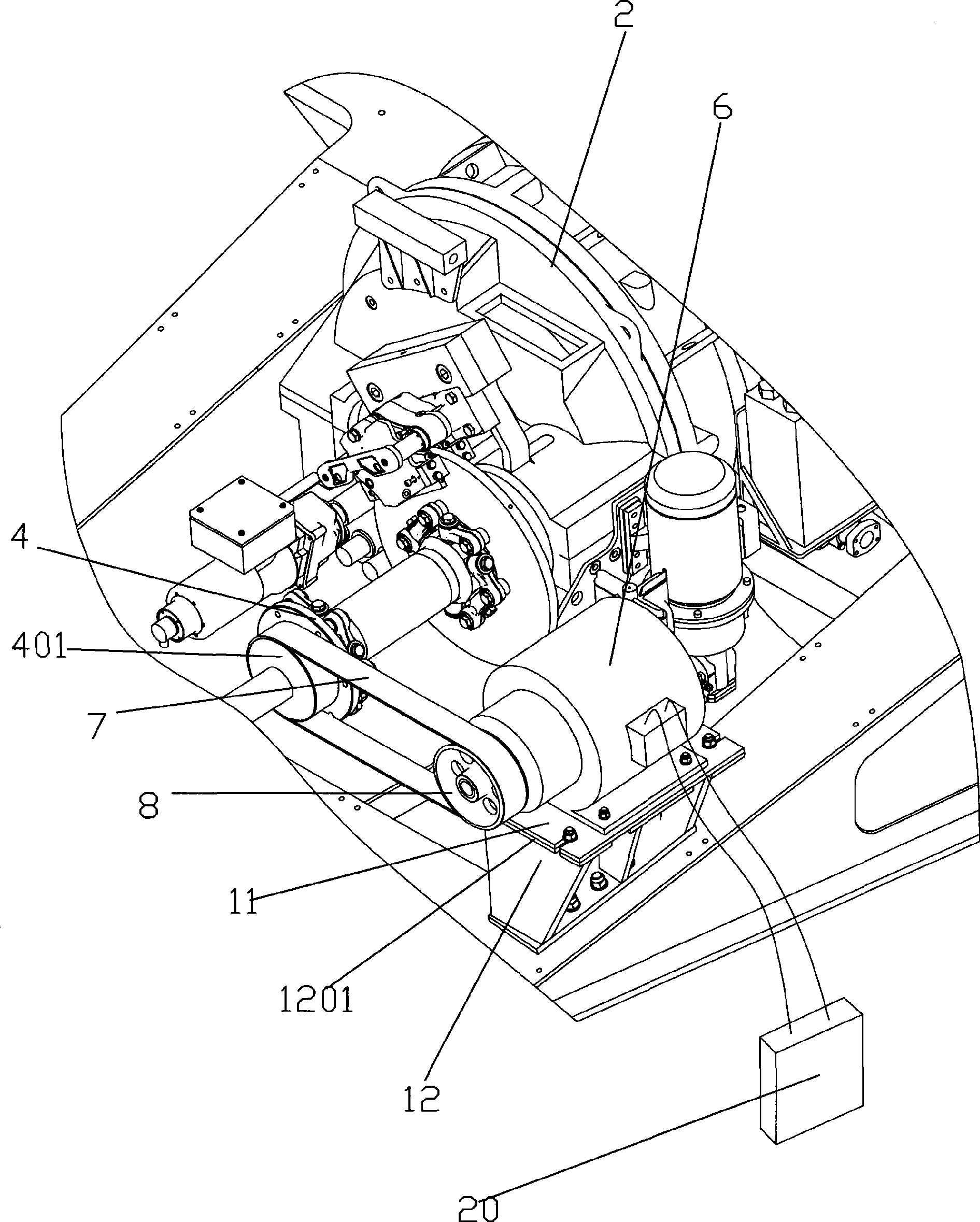

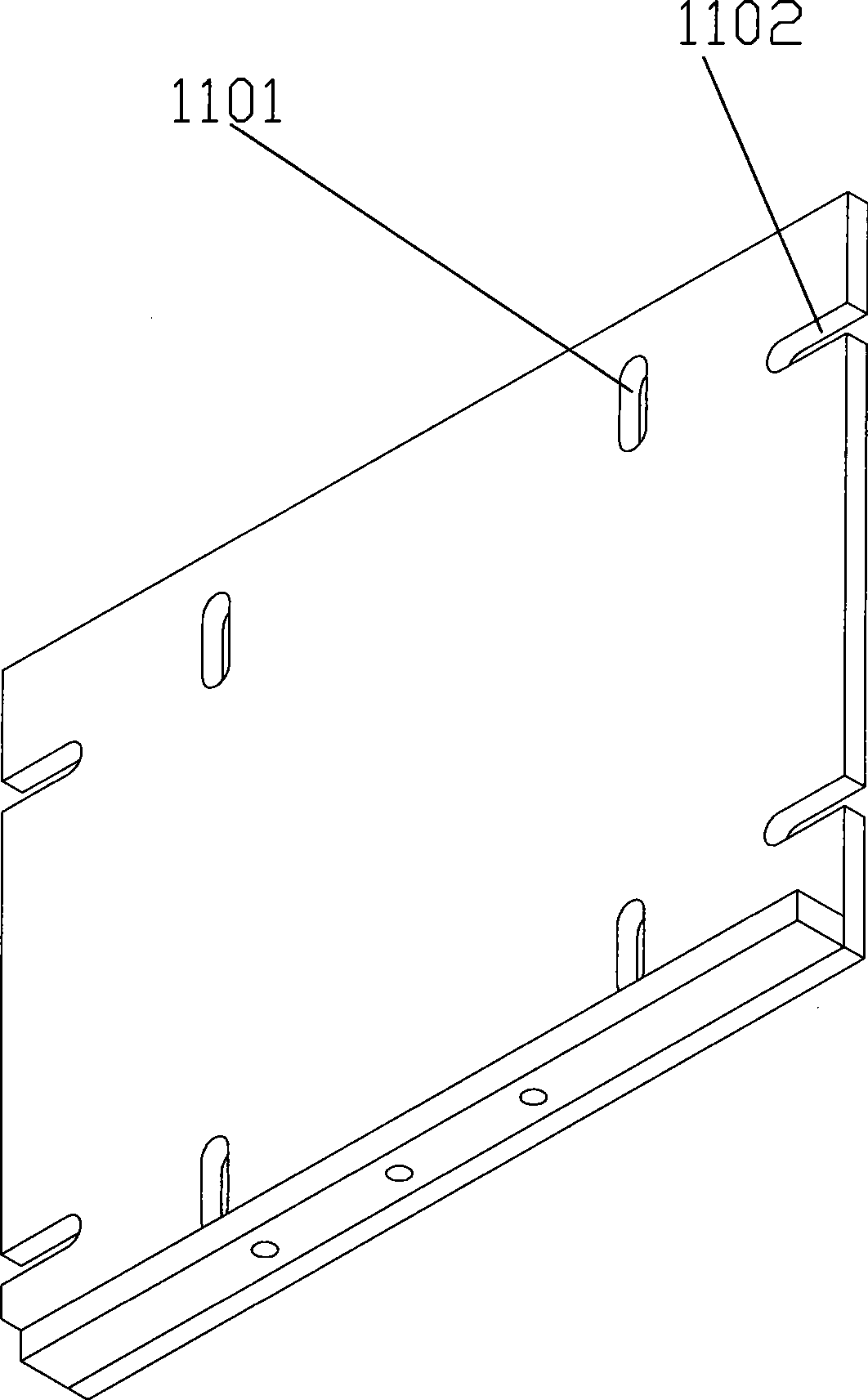

[0019] A complete unit debugging device of a wind power generator, comprising a reduction box 2 installed on a machine base 1, the high-speed end of the reduction box 2 is connected to the generator, and the low-speed end is connected to the wind impeller, and it is characterized in that the reduction box 2 It is connected with the generator 3 by a coupling 4. The coupling 4 includes a coupling expansion sleeve 401, and a motor mounting seat 5 is provided on the frame 1 on one side of the coupling 4. The motor mounting seat 5 is equipped with a motor 6, the motor is connected with a frequency converter 20, the coupling expansion sleeve 401 is connected with the pulley 8 on the motor 6 through a belt 7, and the belt 7 is a flat belt. The motor mounting base 5 includes a motor mounting plate 10 connected to the motor 6 and a motor support frame 12 connected to the motor mounting plate 11 . The motor 6 is bolted to the motor mounting plate 11, and the motor 6 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com