Solar heat absorption pipe and production method thereof

A technology of solar heat absorbing and heat absorbing tubes, which is applied in the directions of solar thermal energy, solar thermal power generation, solar collectors, etc., can solve the problems of high manufacturing cost, complicated manufacturing process, and poor scalability of solar heat absorbing tubes, and achieve structural and The manufacturing method is simple, the heat transfer is fast, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

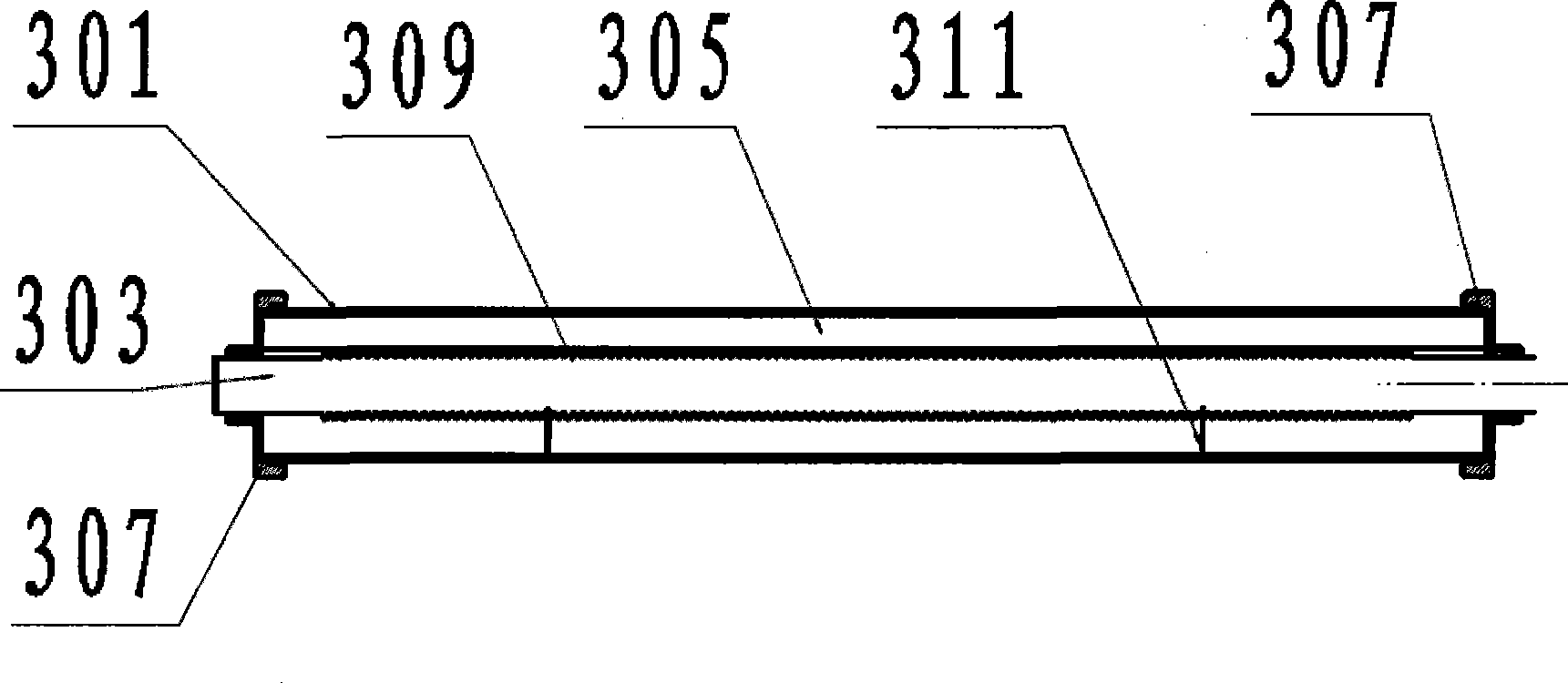

[0034] image 3 It is a structural schematic diagram of the heat absorbing pipe of the first embodiment of the present invention. Such as image 3 As shown, the heat absorbing tube includes a glass tube 301 and a flexible heat conducting tube 309 inside the glass tube 301 .

[0035] The glass tubes are linear and can be connected in series with one or more.

[0036] The flexible heat pipe 309 has a heat-absorbing coating and is arranged parallel to the axis of the glass pipe. The flexible heat pipe 309 can be bent or bent in sections when it is outside the glass tube 301. After being fed into the glass tube 301, it is placed in a straight line, with both ends connected, and has the overall internal compensation function, that is, it has length compensation for thermal expansion and contraction.

[0037] The flexible heat pipe 309 may be a whole flexible corrugate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com