Vehicle layered modeling vibration control method and apparatus

A technology of automobile and control quantity, which is applied in the direction of mechanical oscillation control, non-electric variable control, general control system, etc., and can solve the problem that the suspension quality cannot be decoupled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

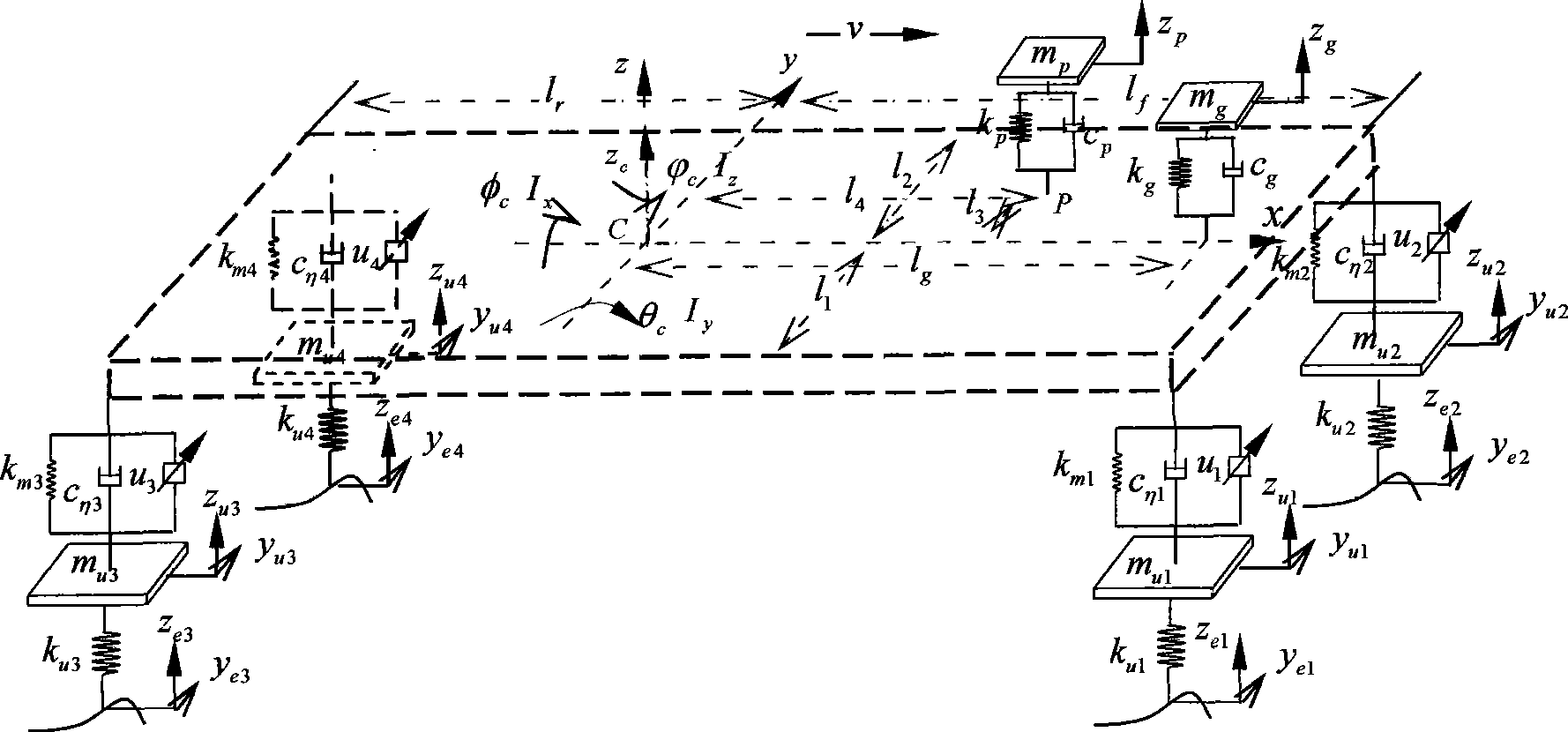

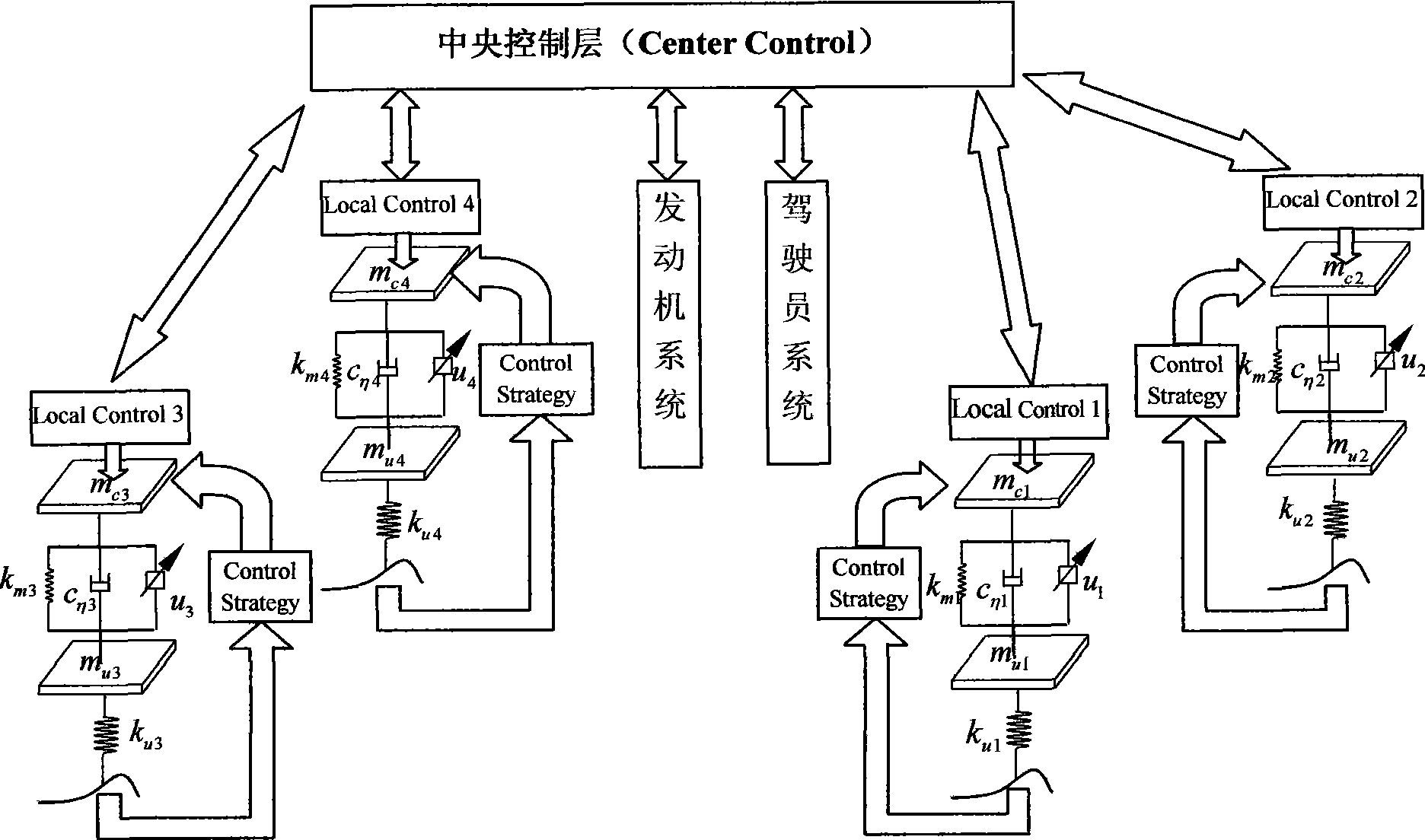

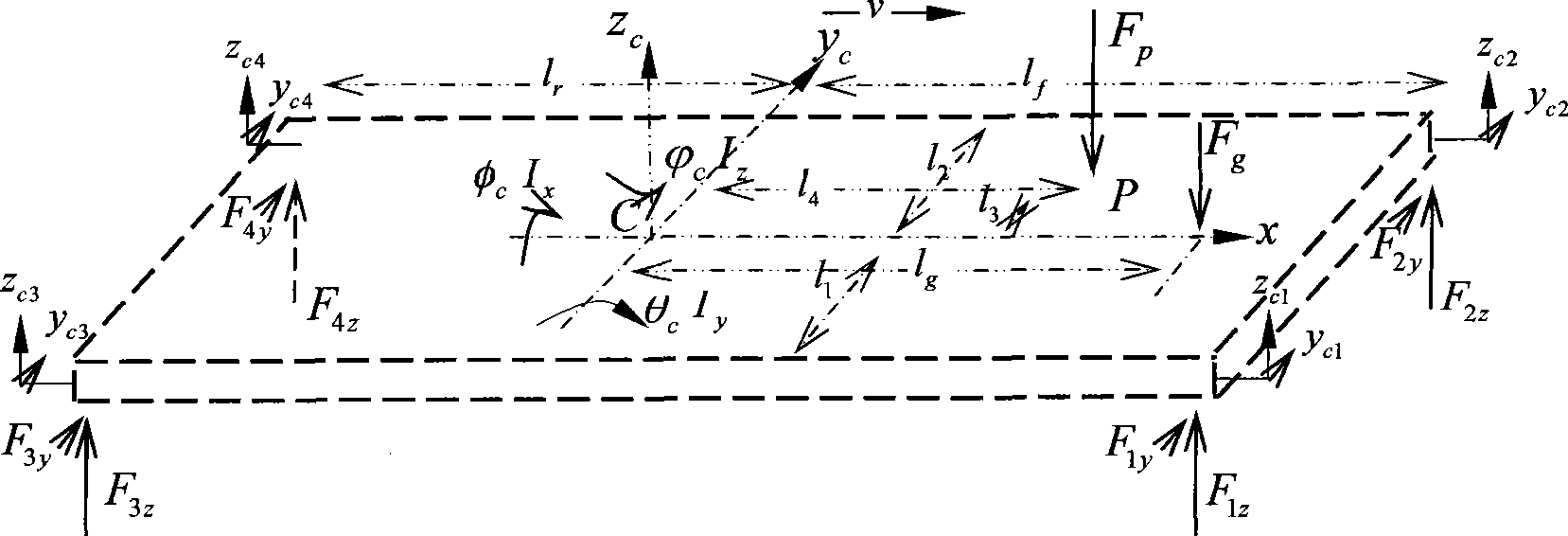

[0053] The solution idea of the method of the present invention is: carry out spatial force analysis on the suspended mass and list its balance equation, and pass through the vertical and lateral movement between the 1# to 4# units on both sides of the front and rear axles and the centroid of the suspended mass. relationship, the transformation can only contain the expressions of the vertical acceleration, lateral acceleration, pitch angular acceleration, roll angular acceleration, and yaw angular acceleration of the suspended mass of units 1# to 4#, so a continuous distribution can be obtained from the mathematical model The suspension mass is regarded as composed of the concentrated mass of four units. Further analysis of the interconnection conditions can regard the traditional overall suspension of a car as a combination of four 1 / 4 controllable suspension systems on both sides of the front and rear axles (vertical, A total of eight two-degree-of-freedom systems in the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com