Low profile side emitting led

A technology of light-emitting diodes and light-emitting devices, applied in semiconductor devices, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

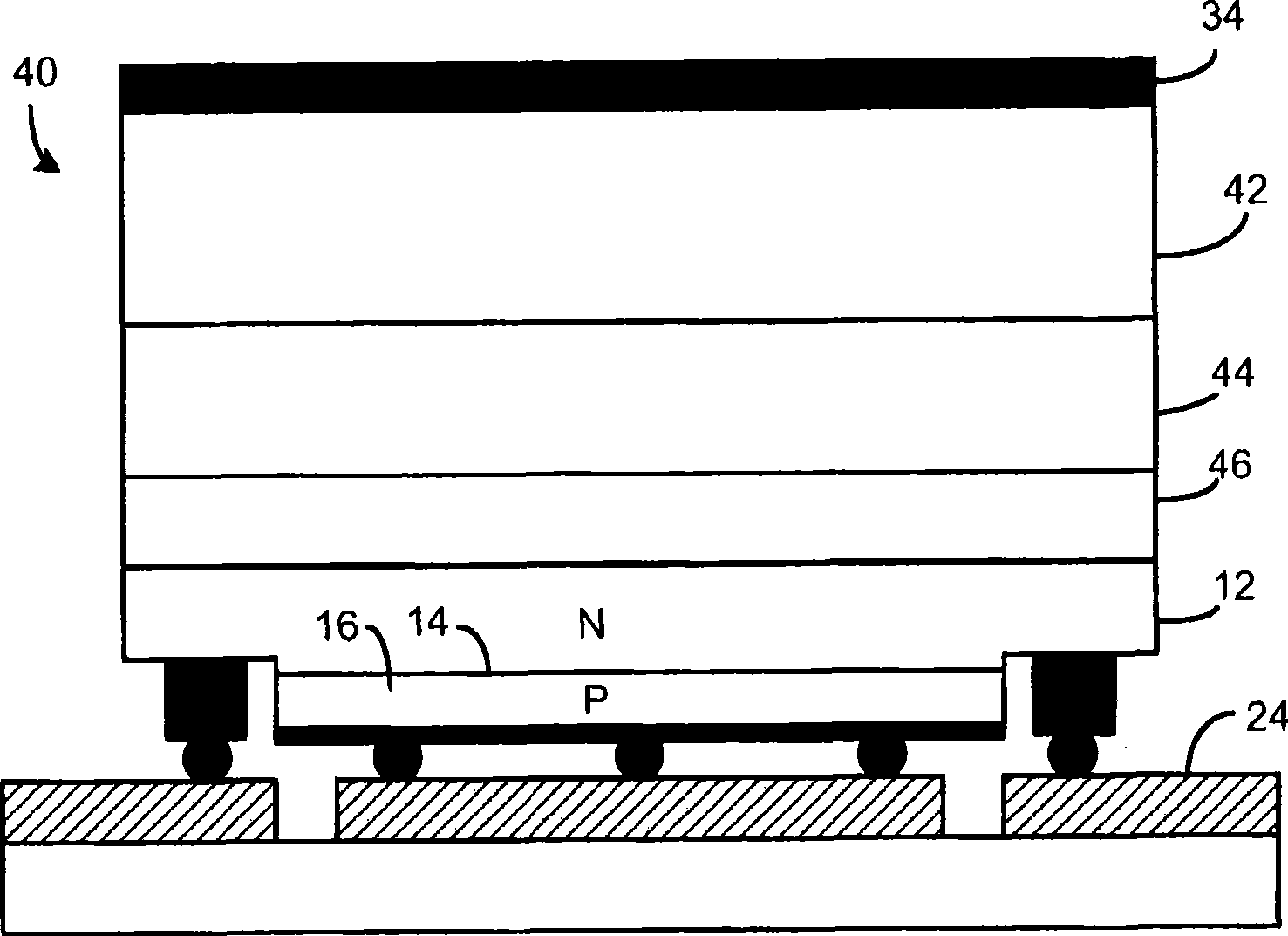

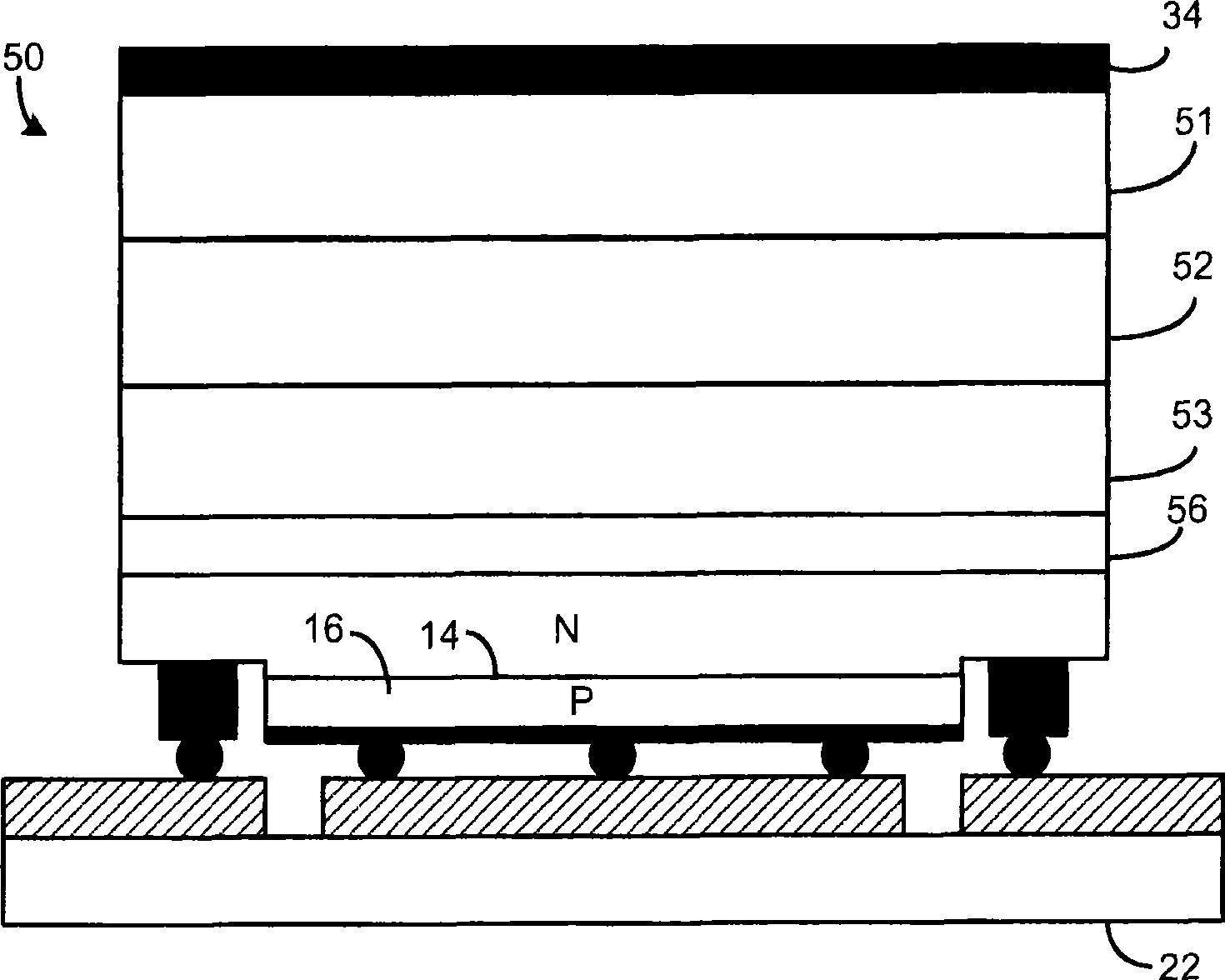

[0024] Embodiments of the present invention include thin profile side-emitting LEDs that enable thin backlight structures for liquid crystal display applications and other applications.

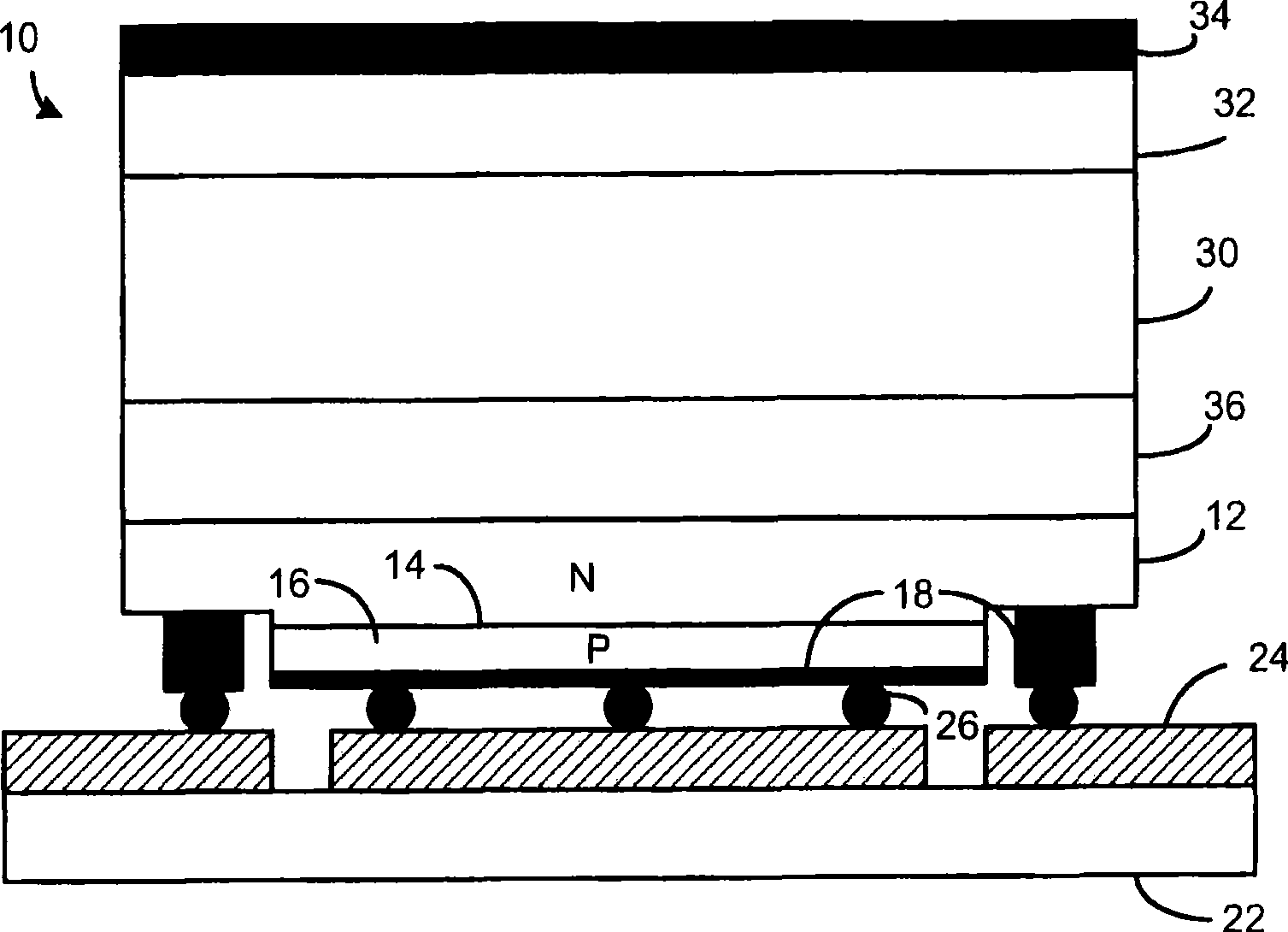

[0025] figure 1 is a side view of a first embodiment of a side-emitting light-emitting diode 10 . In one embodiment, the thickness of the side emitting surface is 0.2-0.4 mm. In another embodiment, the thickness of the side light-emitting surface is 0.2-0.6 mm.

[0026] The invention can be applied to LEDs made of any material system, such as AlInGaP (typically used to emit red to yellow light) or GaN (typically used to emit green to ultraviolet light). Light emitting diodes are formed on a starting growth substrate such as sapphire, SiC, or GaAs, depending on the type of light emitting diode to be formed. Generally, the n-type layer 12 is formed first, then the active layer 14 is formed, and then the p-type layer 16 is formed. The p-type layer 16 is etched to expose a portion of the unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com