Parallel type vehicle oil electric mixed dynamic system

An oil-electric hybrid and parallel technology, which is applied in hybrid vehicles, power units, electric vehicles, etc., can solve the problems of reduced vehicle driving performance, complicated control, and many steps, and achieves light additional weight, simplified control process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

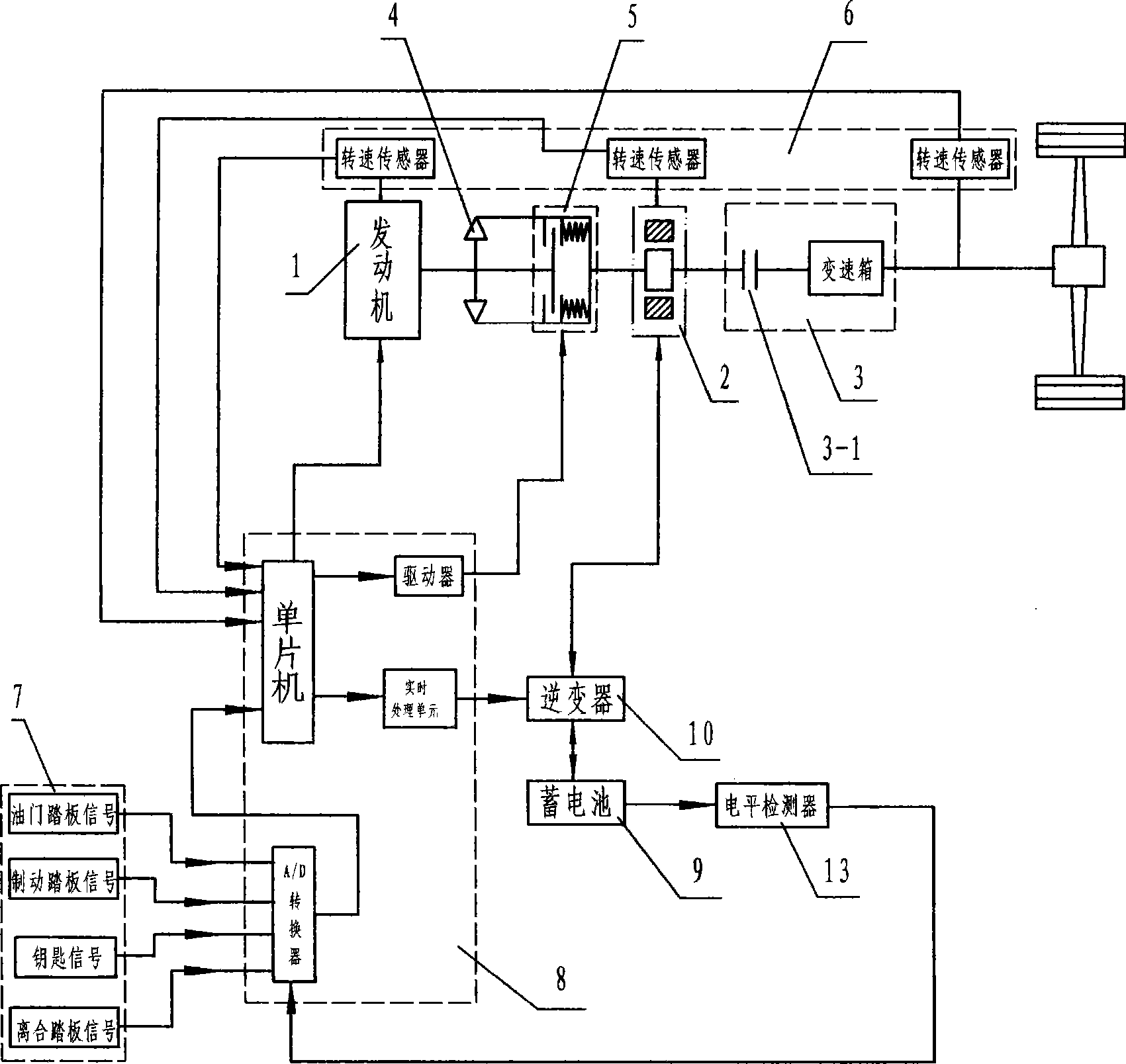

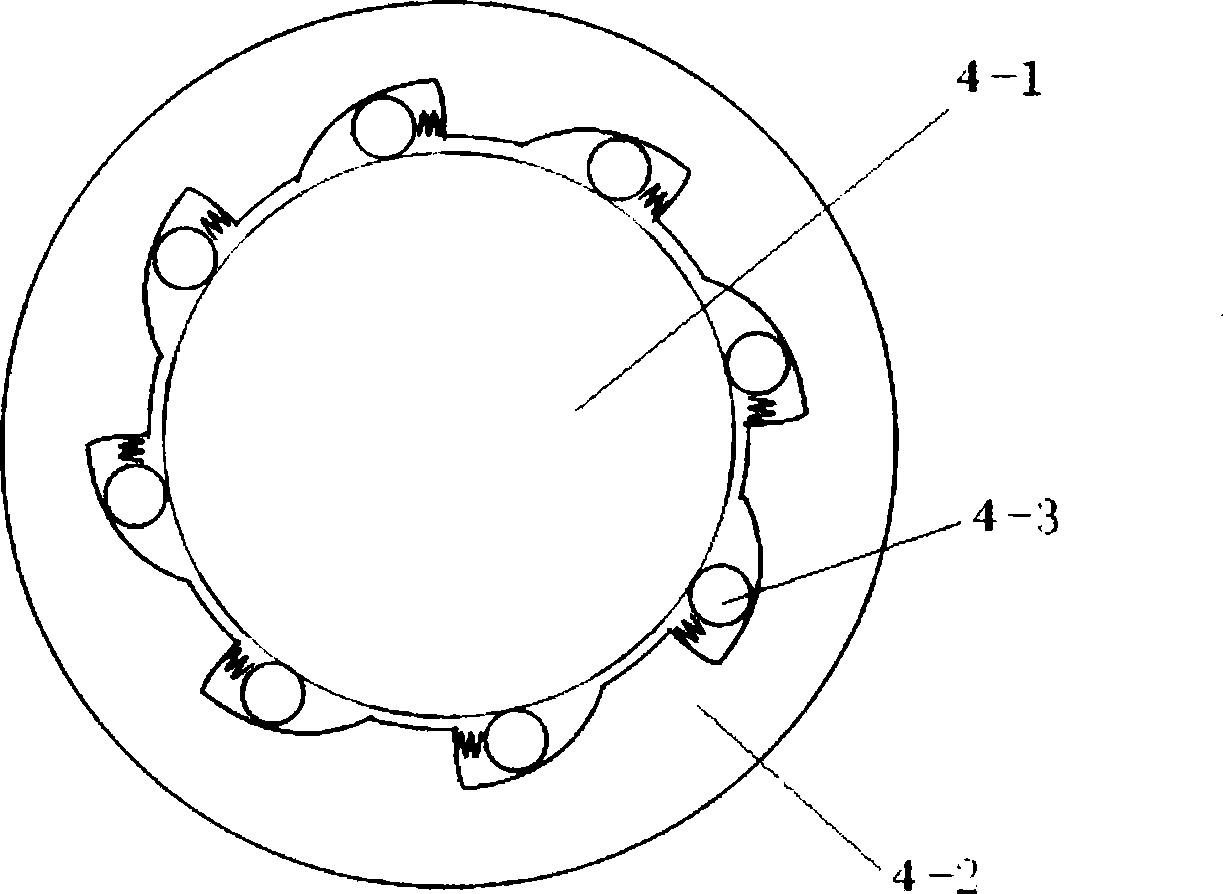

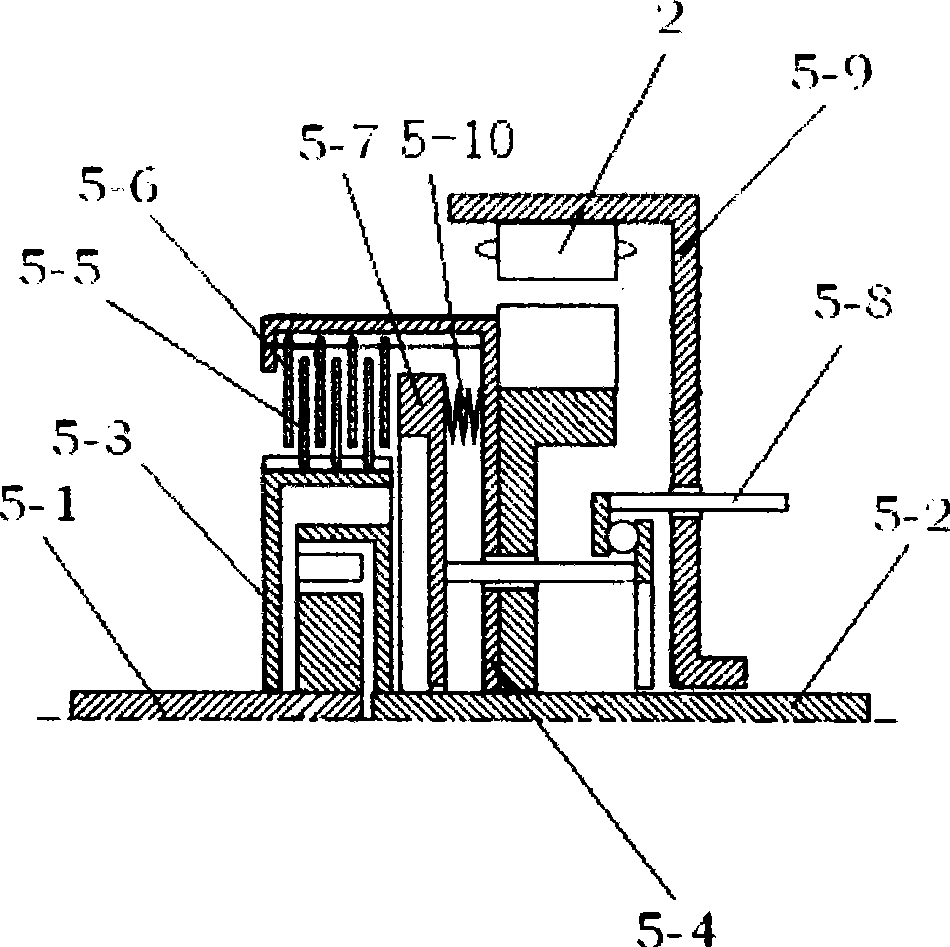

[0019] see figure 1 , it includes an engine 1, a motor 2, a gearbox 3, one end of the shaft of the motor 2 is connected with the shaft of the engine through a one-way clutch 4 and a torque-limiting clutch 5 (or a three-speed clutch), the The other end of the motor 2 shaft is connected with the input shaft of the gearbox 3, and the output shaft of the gearbox is connected with the drive shaft of the wheel, wherein the one-way clutch 4 and the torque limiting clutch 5 are connected in parallel, and one end of them is connected with the engine shaft Connect the other end to the motor shaft. The one-way clutch 4 is in a disengaged state when the engine speed is lower than the motor speed, allowing free rotation between the two shafts, and is in a closed state when the engine speed tends to exceed the motor speed, that is, to lock the two shafts together so that the two shafts can Rotating at a certain speed, at this moment, the torque output by the engine can be directly transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com