Method for producing high-octane petrol

A technology for high-octane gasoline and heavy gasoline, applied in gasoline stabilization, petroleum industry, cracking, etc., can solve the problems of large olefin loss and low gasoline yield, increase gasoline yield and octane number, and avoid olefins The effect of excessive loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

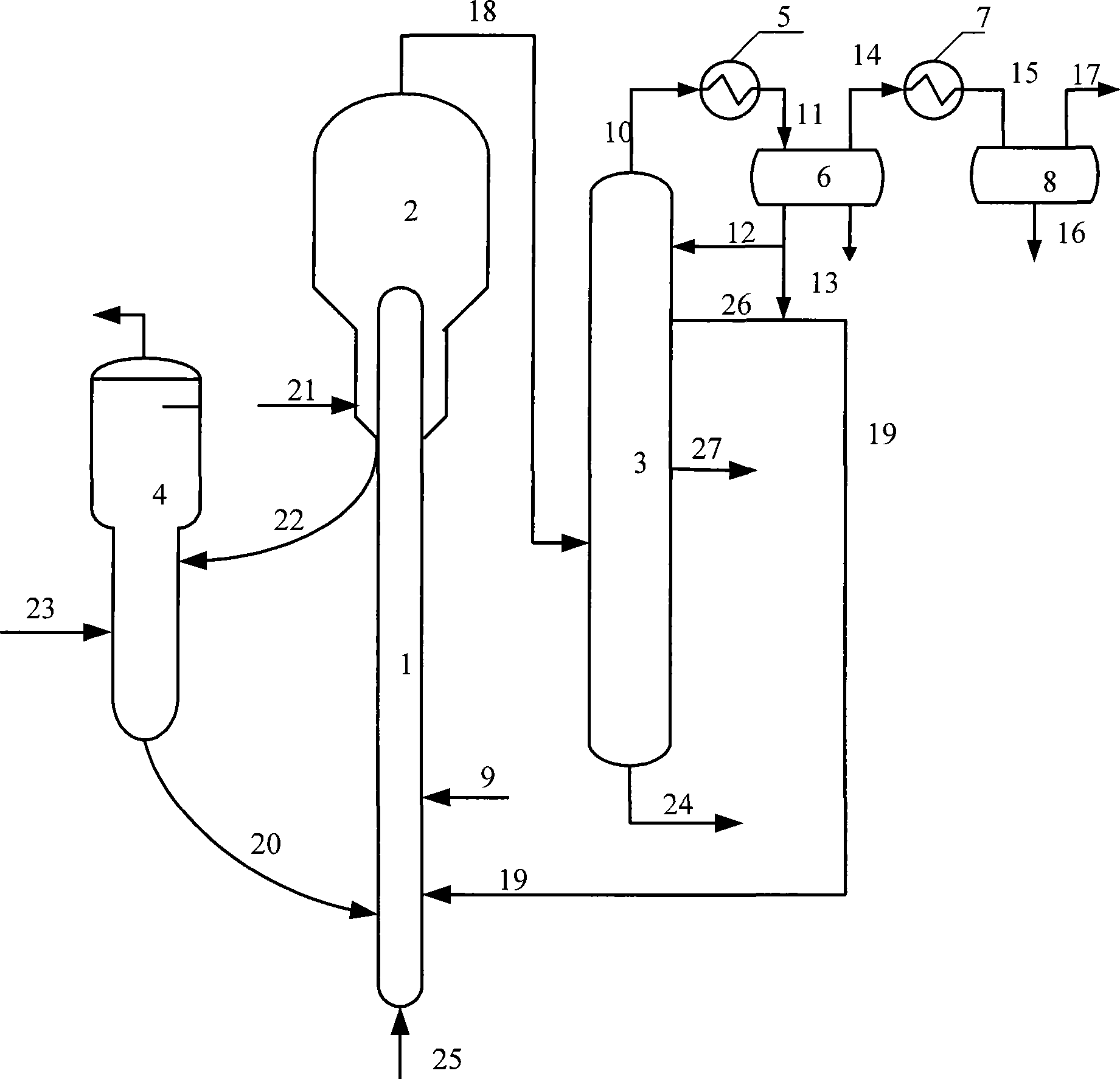

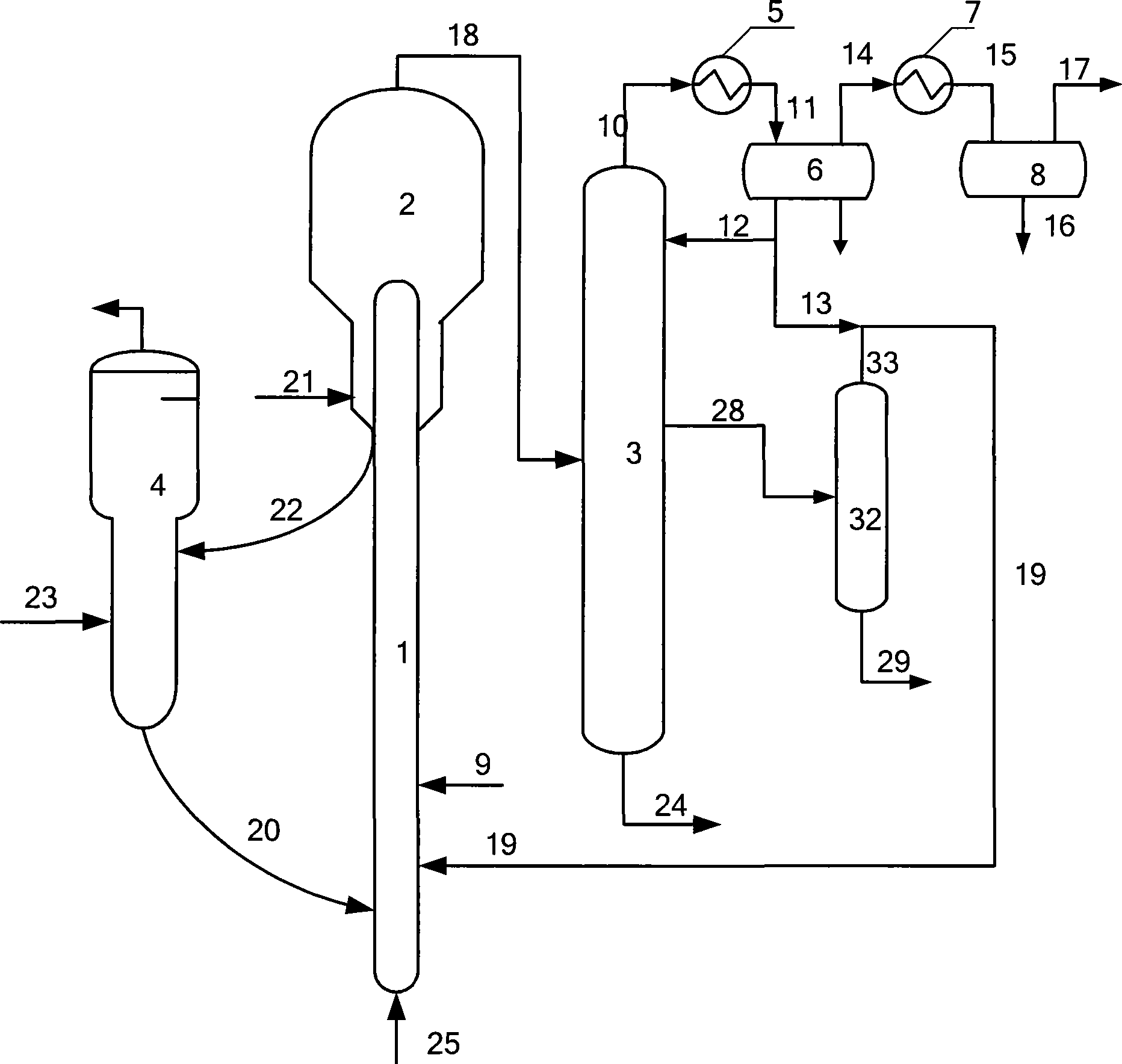

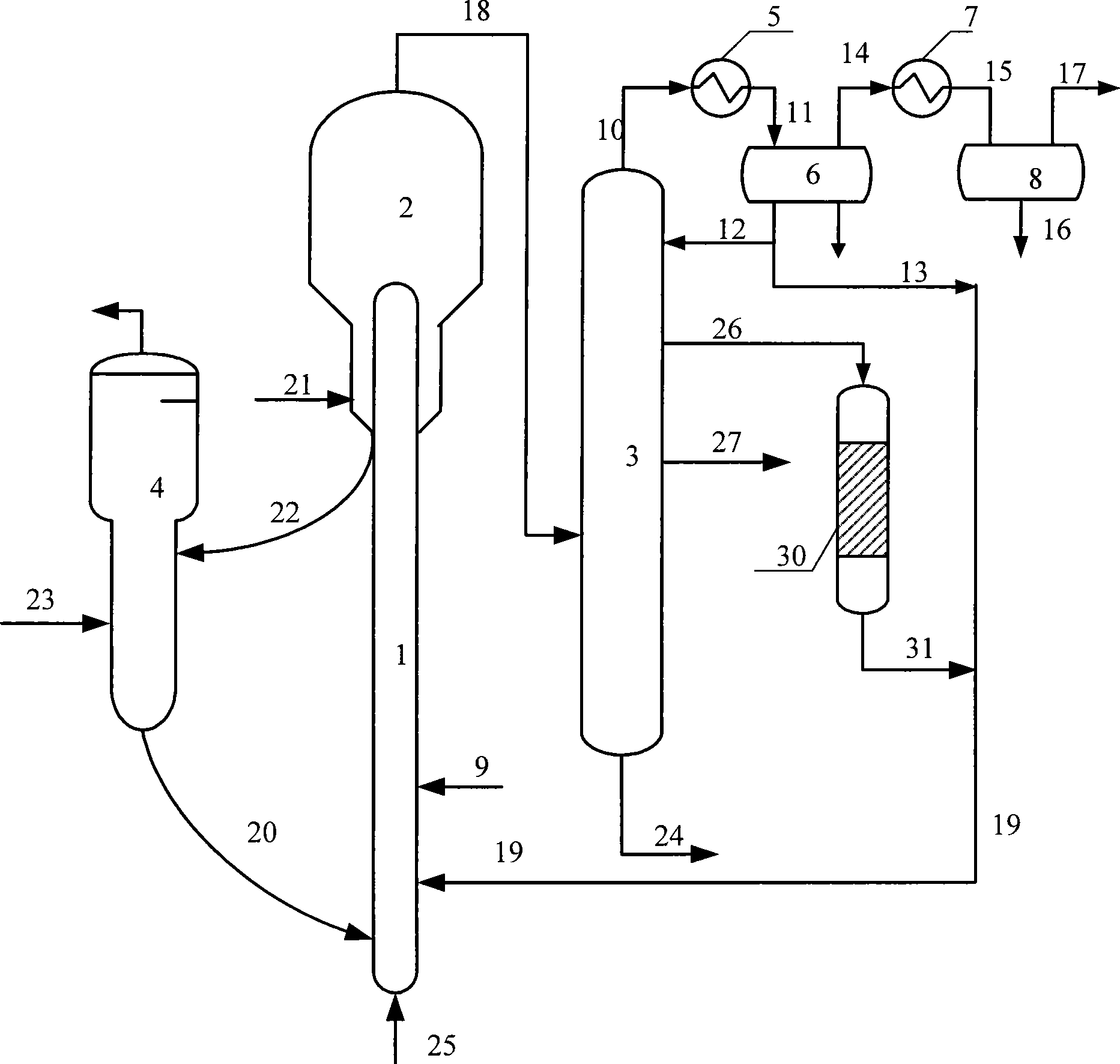

Method used

Image

Examples

Embodiment 1

[0037] This example shows that the method provided by the invention can increase the yield of catalytic cracking gasoline and increase the octane number of gasoline.

[0038] Using the test device in the comparative example, the catalytically cracked gasoline is cut into light and heavy gasoline by distillation. Among them, the distillation range of heavy gasoline is 160-220°C. The catalytic cracking diesel oil is cut into light and heavy diesel oil through distillation, wherein the distillation range of light diesel oil is 168-281°C. Mix heavy gasoline and light diesel oil into mixed oil, enter the riser reactor from the bottom of the catalytic cracking raw material nozzle, and contact with catalyst MLC-500 for reaction. The raw material oil and reaction conditions are the same as those in the comparative example. After the reaction, the oil gas and catalyst enter the raw material feeding reaction section upwards, and the generated oil gas and spent agent continue to enter t...

Embodiment 2

[0041] This example shows that the method provided by the invention can increase the yield of catalytic cracking gasoline and increase the octane number of gasoline.

[0042] The test device, raw oil and catalytic cracking reaction conditions used in this example are the same as those in Example 1, except that the light diesel oil is firstly hydrotreated and then mixed with catalytic cracked heavy gasoline into a medium-sized riser reactor for reaction. The conditions for hydrofining are: reaction temperature is 350°C, pressure is 3.2MPa, volume ratio of hydrogen to oil is 300:1, and volumetric space velocity is 2.5h -1 . The properties of the mixed oil are shown in Table 4. The product distribution and properties are shown in Table 5.

[0043] It can be seen from Table 5 that compared with Example 1, the gasoline yield increased by 1.18 percentage points after the hydrogenated mixed oil was re-refined, but the aromatics content in gasoline was reduced by 10.67 percentage po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com