Method for improving non-mask photo-etching definition

A maskless lithography and resolution technology, which is applied in the field of improving the resolution of maskless lithography, can solve the problems of high feature size, inability to effectively improve resolution, and inability to meet integration requirements, and achieve high resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description, the term "pixel point" refers to a point forming an actual required exposure pixel, and "exposure point" refers to a point formed by focusing a nanoscale light beam. It should be noted that in the context of the present invention, a "point" is an area occupying a certain two-dimensional distribution.

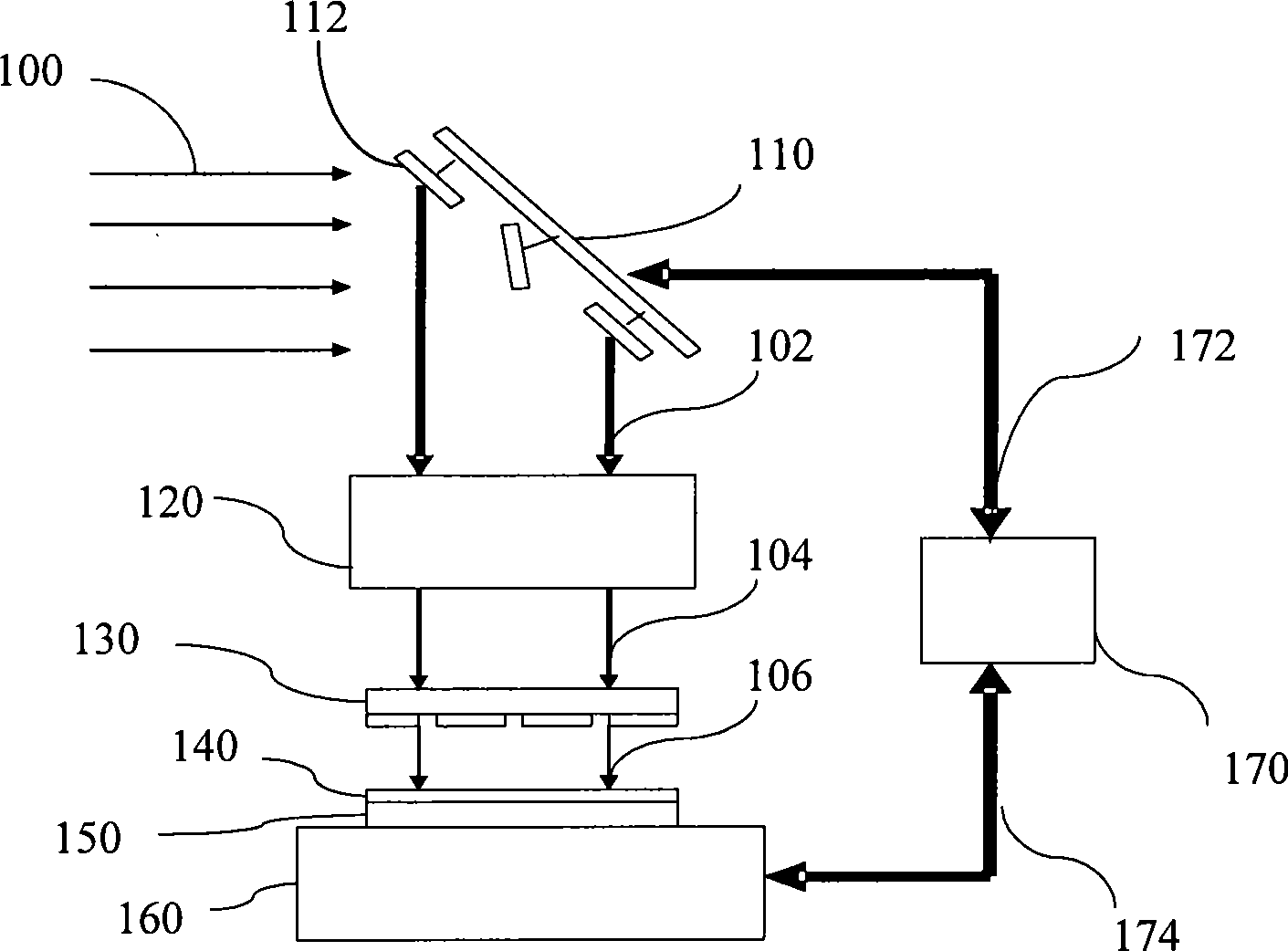

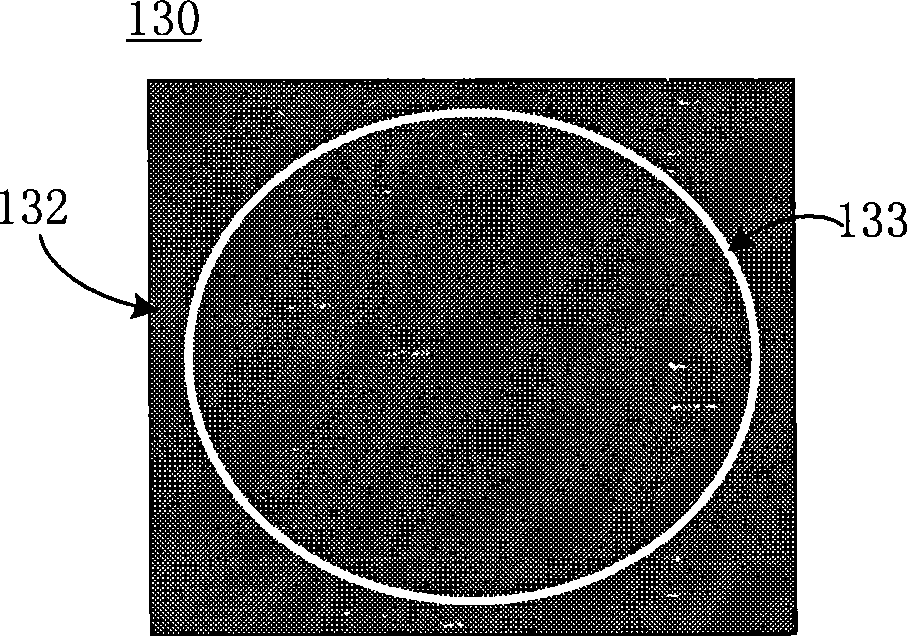

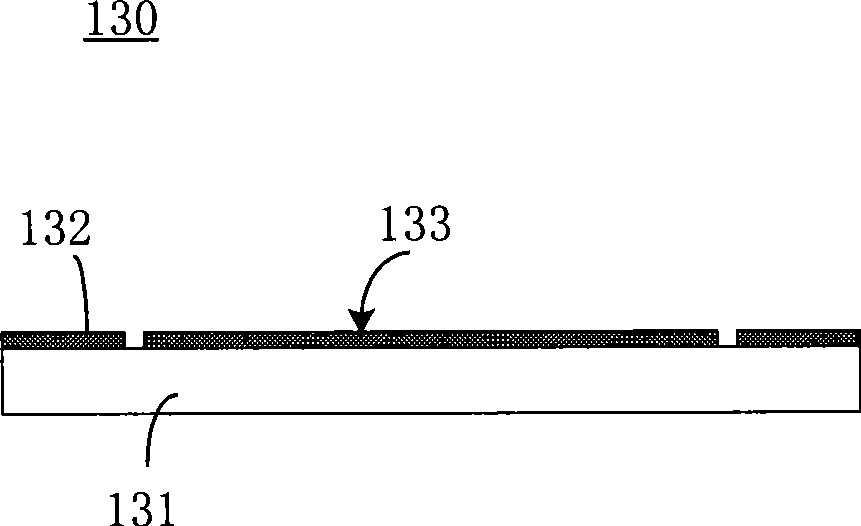

[0032] First please refer to figure 1 As shown, the structure of a maskless lithography system according to an embodiment of the present invention is as follows. A light source (not shown) that provides light 100 for exposure, such as ultraviolet light or laser light. A micro-mirror array 110 has a plurality of micro-mirrors 112 with controllable reflection directions on it, and each micro-mirror 112 can choose whether to reflect the light beam irradiated by the light source to the optical projection device 120 by changing its reflection direction, that is, The "on" and "off" controls are performed to form a micro-beam 102 with a width of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com