Electric connection structure and method for heat radiating device and switching circuit board

A technology for switching circuit boards and cooling devices, which is applied in the fields of electrical digital data processing, cooling/ventilation/heating transformation, and instruments, etc., which can solve problems such as inconvenience in maintenance operations, enlarged space of the housing 20, and increased processing costs, etc., to achieve Save processing time, reduce cost, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

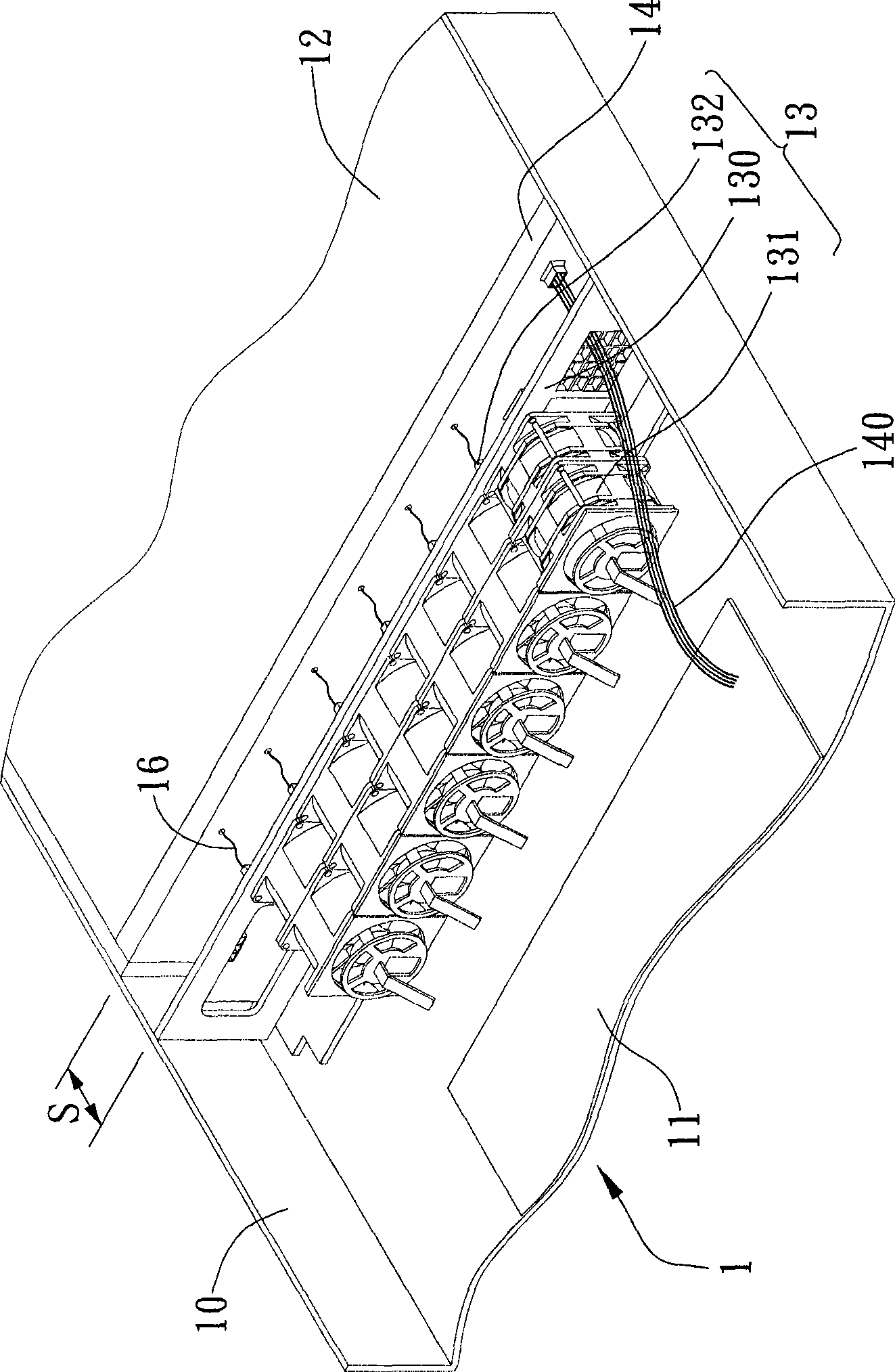

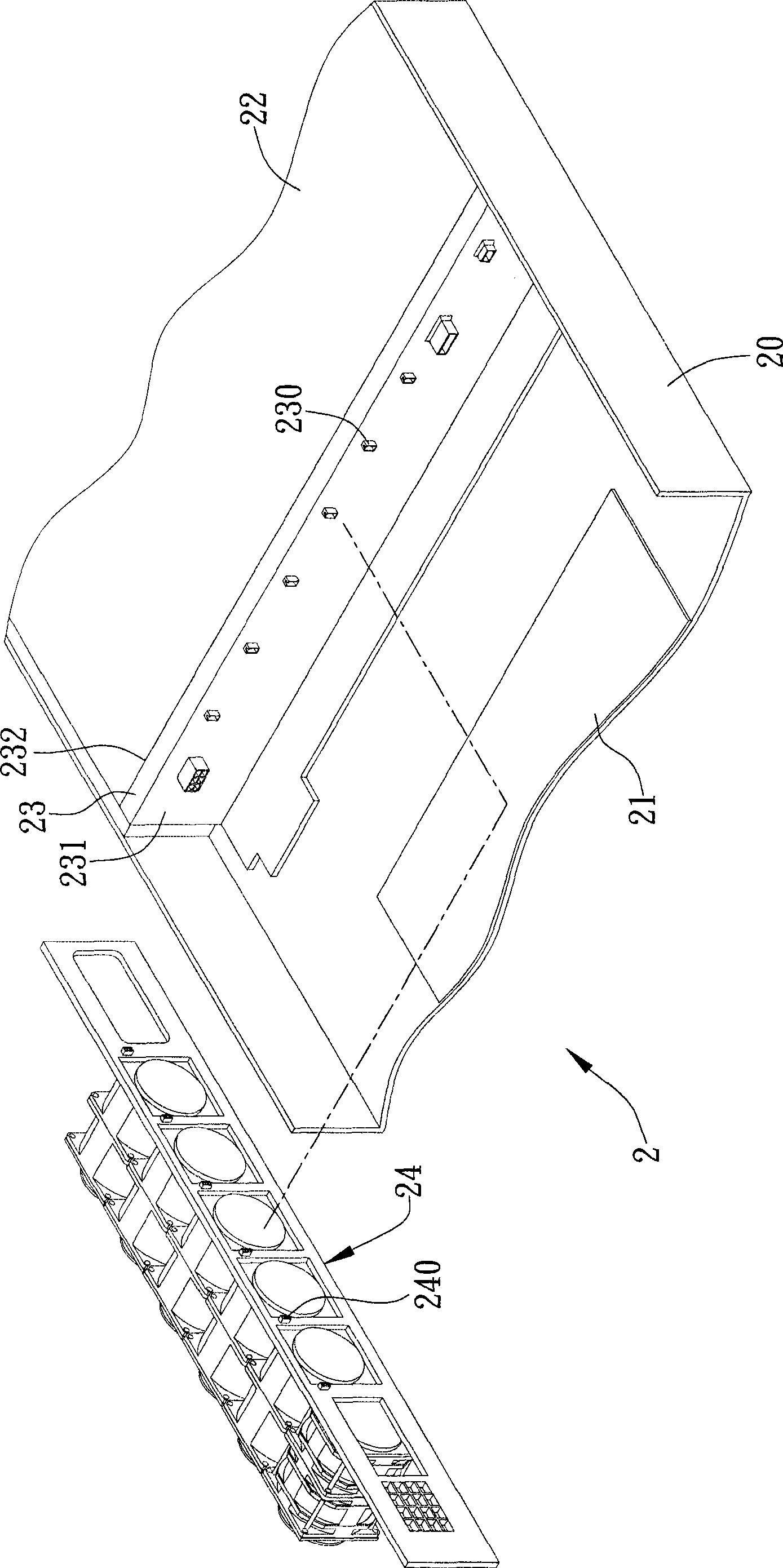

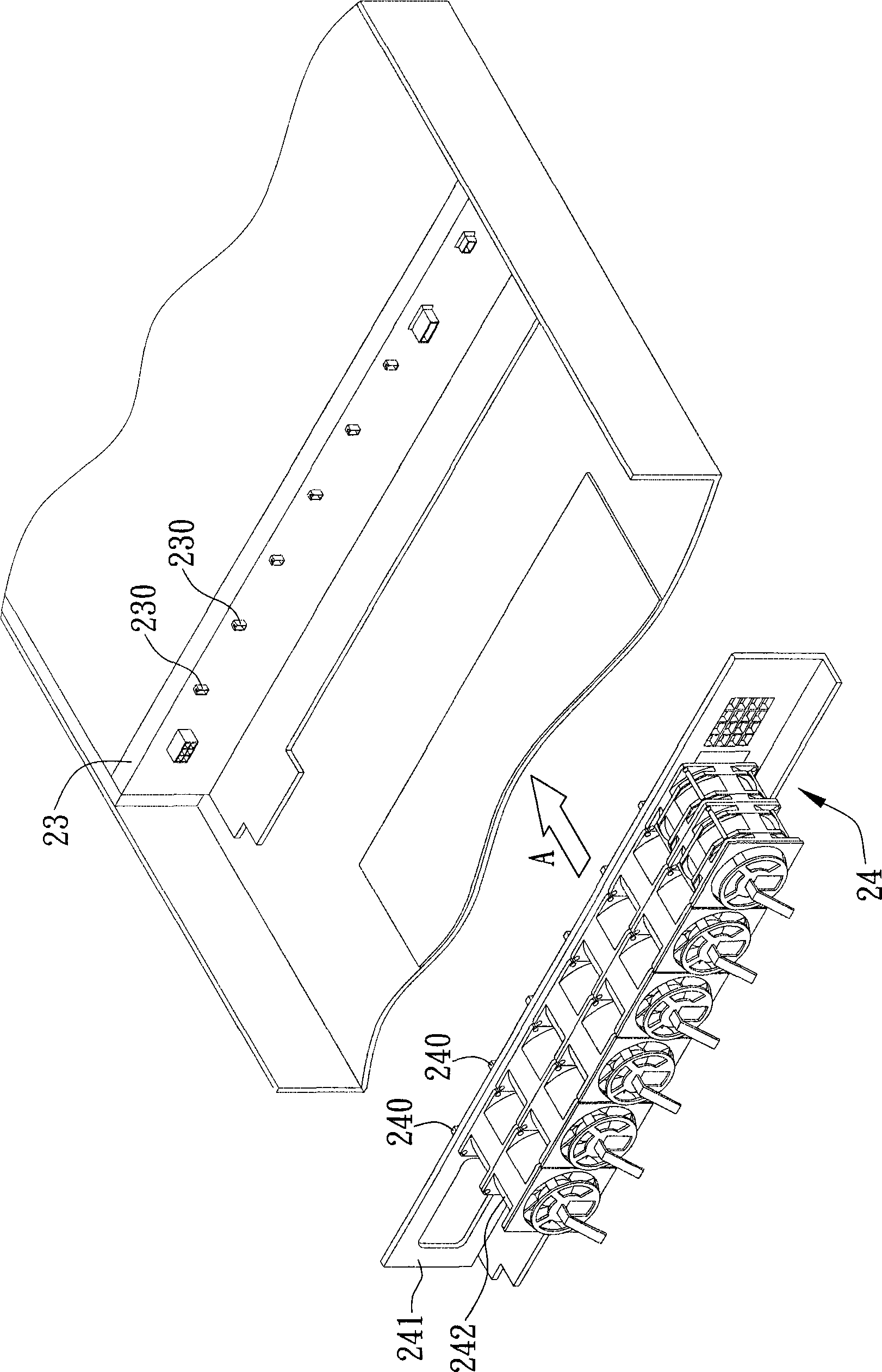

[0049] see figure 2 , is a drawing in which the electrical connection structure of the heat dissipation device and the interposer circuit board of the present invention is applied to an electronic device, such as a server, a notebook computer device, a personal computer, and the like.

[0050] The electronic equipment 2 has a casing 20, a motherboard 21, a hard disk 22, a heat sink 24, and an adapter circuit board 23. The motherboard 21 and the hard disk 22 are all installed in the housing 20, and the adapter circuit board 23 is fixed on The casing 20 has a first surface 231 and a second surface 232 opposite to the first surface 231, the second surface 232 is electrically connected to the hard disk 22, the first surface 231 is elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com