Installation method for inductor of duplexer

An installation method and duplexer technology, applied in the direction of transformer/reactor installation/support/suspension, etc., can solve problems such as inconsistent welding positions of wires, affecting product electrical performance indicators, and difficult operation of solder joints, etc. Damage, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

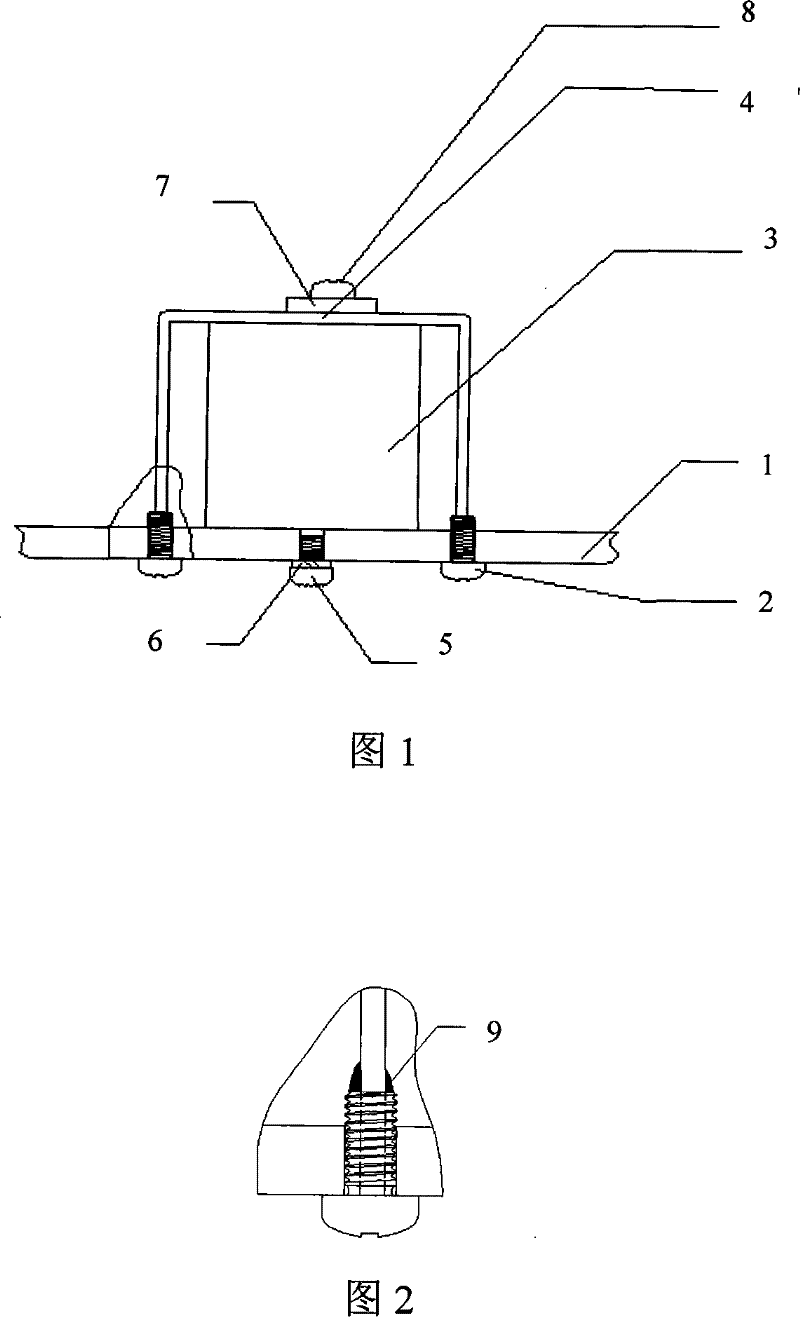

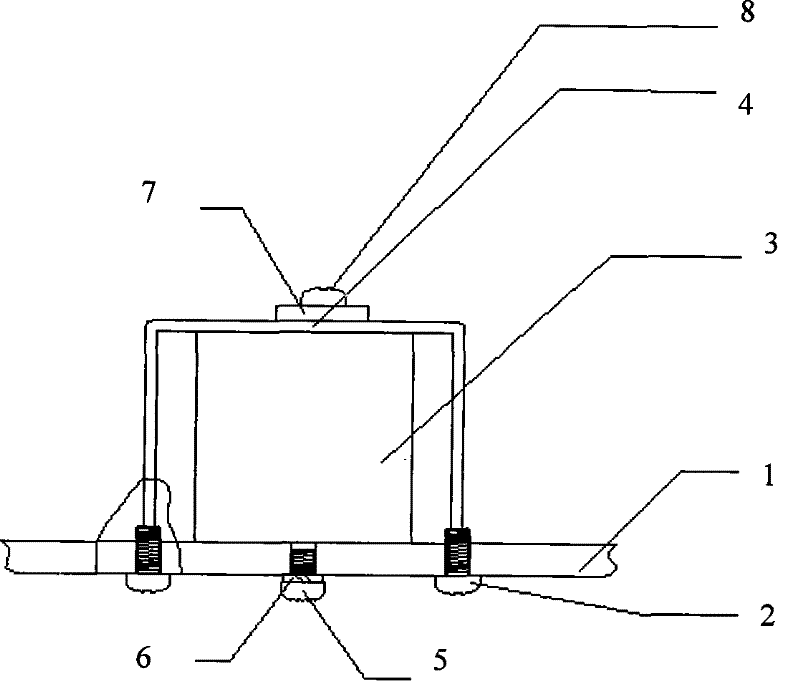

[0023] As shown in Figures 1 and 2, an installation method for duplexer inductors uses the small diameter of the middle hole of the through-hole screw 2, which can play a good role in positioning. When the metal wire 4 is inserted into the hole of the through-hole screw 2 Among them, since the diameter of the middle hole of the metal wire 4 and the through-hole screw 2 is similar to 0.8-1.4mm, the metal wire 4 can not be shaken back and forth to ensure that the position of the induction welding is uniquely determined; The metal wire 4 is fixed on the block fixture 3 by the metal pressure piece 7, as long as the size of the fixture 3 can be ensured, the height of the inductance can be well controlled; the welding area is reduced during welding, the welding quality is guaranteed, and the operation can be eliminated at the same time. human factors in.

[0024] Wherein, the material of the through-hole screw 2 can be brass surface coated with a ternary alloy; the block clamp 3 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com