Fungicidal compositions and methods of using the same

A composition, fungicidal technology, applied in the directions of application, small hides/large hides/leather/fur treatment, leather impregnation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

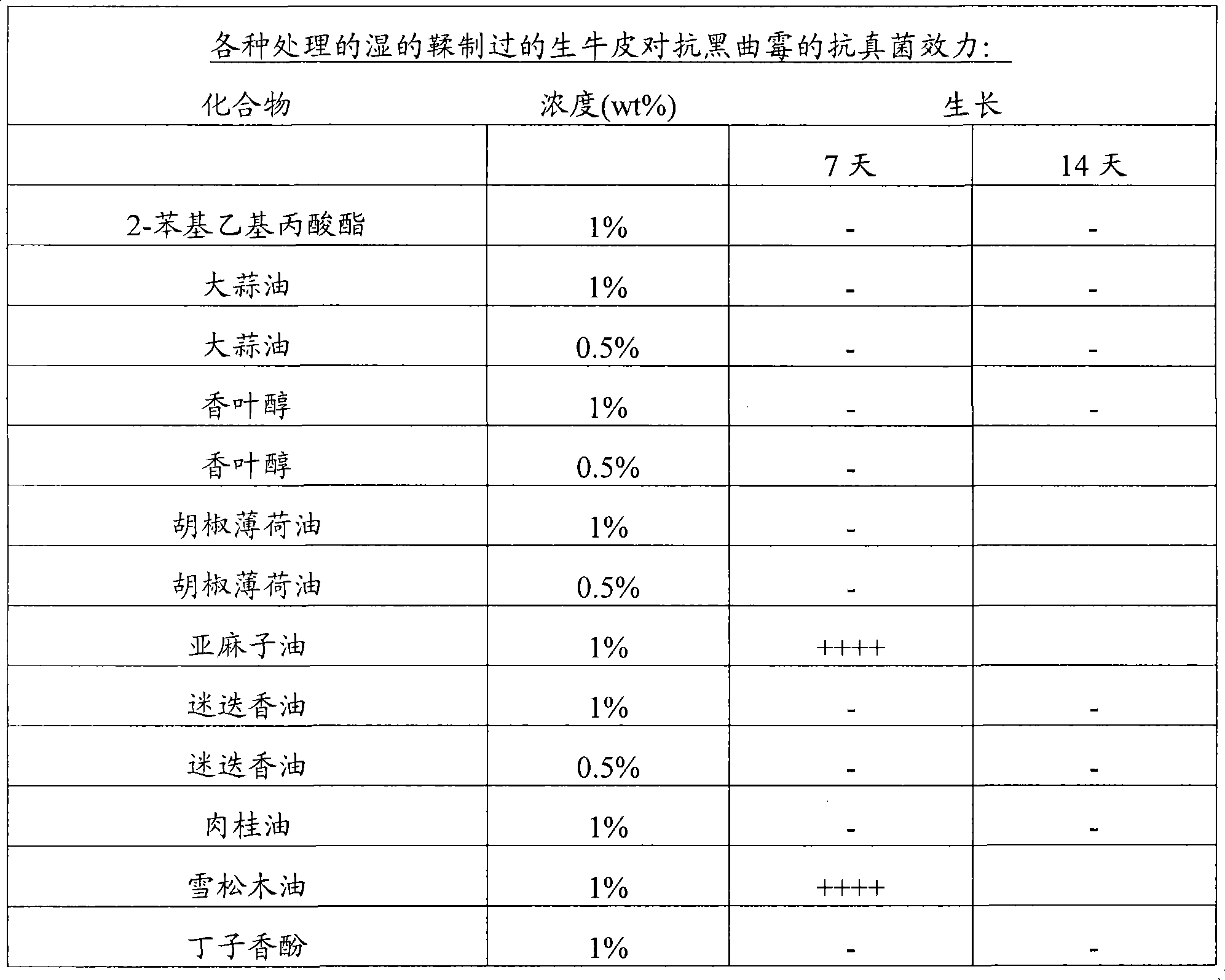

[0074] Each material shown in table 1 is added in the inorganic salt glucose culture medium with following composition, to screen the antifungal activity of these materials: 0.7g KH 2 PO 4 ;0.7g MgSO 4 .7H 2 O; 1 g NH 4 NO 3 ; 0.005g NaCl; 0.002g FeSO 4 .7H 2 O; 0.002g ZnSO 4 .7H 2 O; 0.001g MnSO 4 .7H 2O; 10 g glucose; 100 ml water. The pH of the medium was adjusted to 6 using 1N NaOH. 50ml of medium was dispensed into 250ml flasks and autoclaved at 121°C for 20 minutes. The fungus tested, Aspergillus niger, was grown on potato dextrose agar for 7-10 days. A spore / hyphae suspension of the fungus was prepared by washing the spores / hyphae from a slant with sterile saline into a bottle containing 30 ml sterile saline and shaking. Each chemical was added to sterile mineral salt medium at the desired concentration and each flask was inoculated with a fungal suspension such that the final fungal count was about 1 x 10 6 cfu / ml. The inoculated samples were incubated a...

Embodiment 2

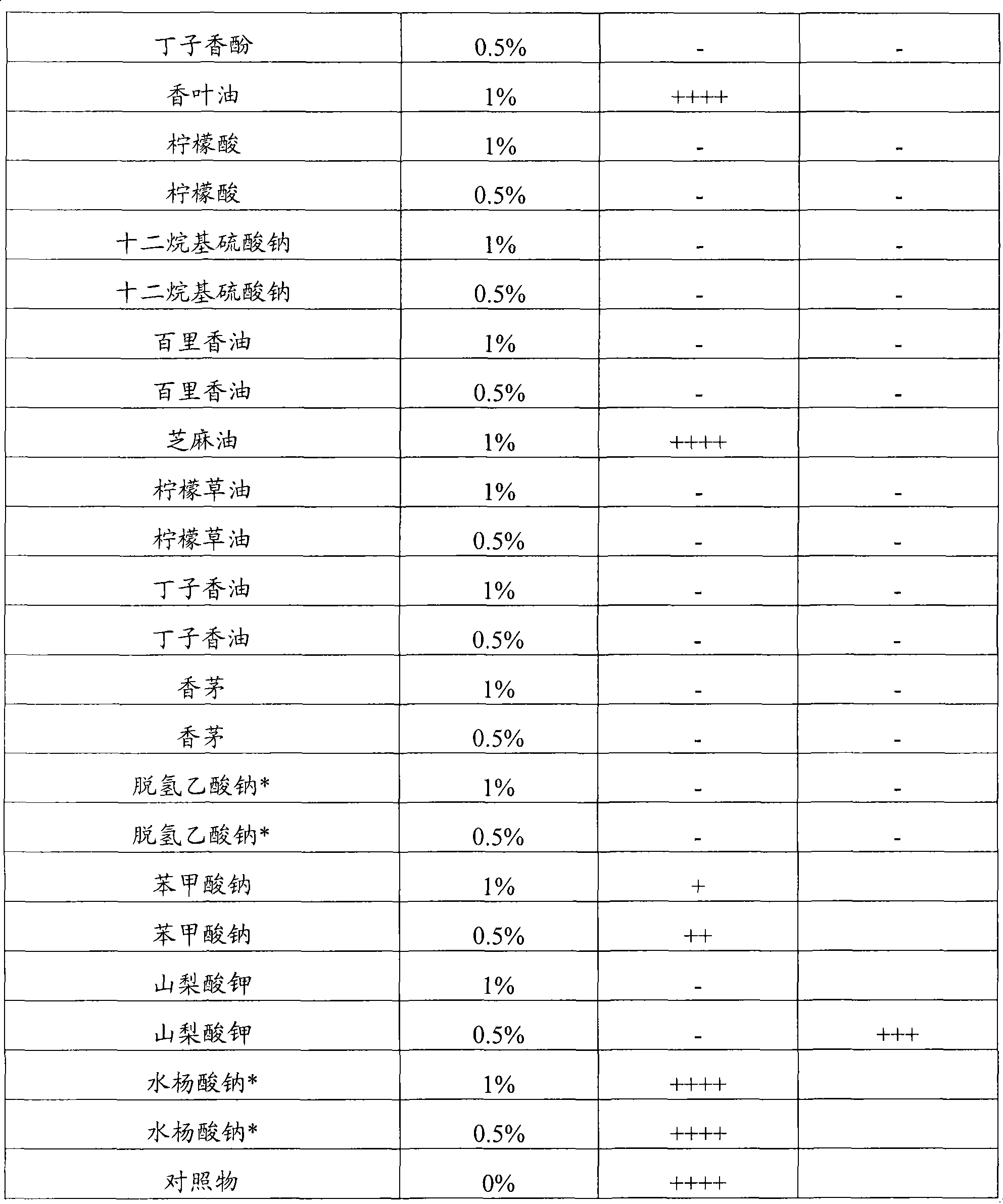

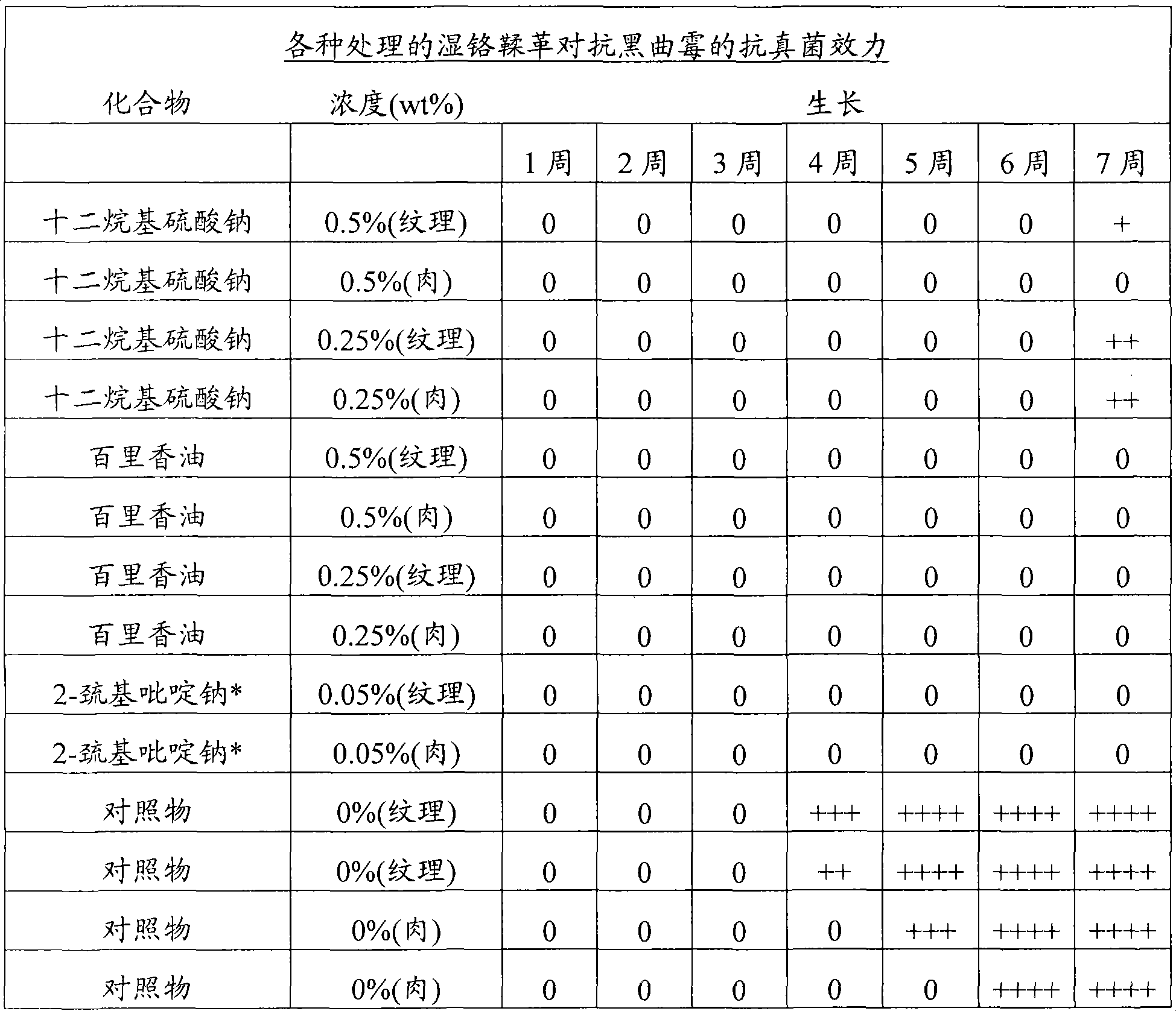

[0086] Those substances which demonstrated significant antifungal activity in Example 1 above were further tested in vitro on wet tanned rawhide hides (wet chrome tanned leather). A 1 inch square piece of wet chrome-tanned leather that had not been previously treated with fungicides was dipped in either 0.5% or 0.25% (wt %) mixtures of the various actives in water. Sodium 2-mercaptopyridine was included as a positive control among the test substances. The test organism A. niger was grown on potato dextrose agar for 5 days in petri dishes. The wet chrome-tanned leather pieces were placed on top of each section of a curved glass rod, preventing direct contact with the "lawn" of A. niger. Therefore, limiting the exposure of wet chrome-tanned leather to airborne A. niger spores is one of the most common ways of simulating the exposure experienced in practice. For each active substance and concentration studied, pieces of wet chrome-tanned leather were suspended with the grain si...

Embodiment 3

[0097] As shown in Table 3, some of the minimal risk fungicides identified above were further tested for resistance to industrial isolates of penicillium samples (Penicillium sp). This particular "wild strain" of penicillin was isolated from commercial wet chrome tanned leather heavily contaminated with the mold. In this case, the included molds significantly stain the wet chrome tanned leather, resulting in a significant loss of commercial value. Once again, a 1 inch square piece of wet chrome tanned leather was dipped in a mixture of active material in water, this time at concentrations of 1% and 0.5%. Mold exposures were performed in Petri dishes as in Example 2, but using penicillin samples as test organisms. Again, the resistance of wet chrome tanned leather treated with sodium lauryl sulfate or thyme oil was significantly improved over the unprotected control. The commercial fungicide Prosan from Buckman Laboratories International included as a positive control TM 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com