Power conversion apparatus

A power conversion device and conversion technology, which are applied to output power conversion devices, electrical components, and irreversible DC power input into AC power output, etc., can solve problems such as increasing impedance, increasing the number of components, and increasing costs. , to achieve the effect of stable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

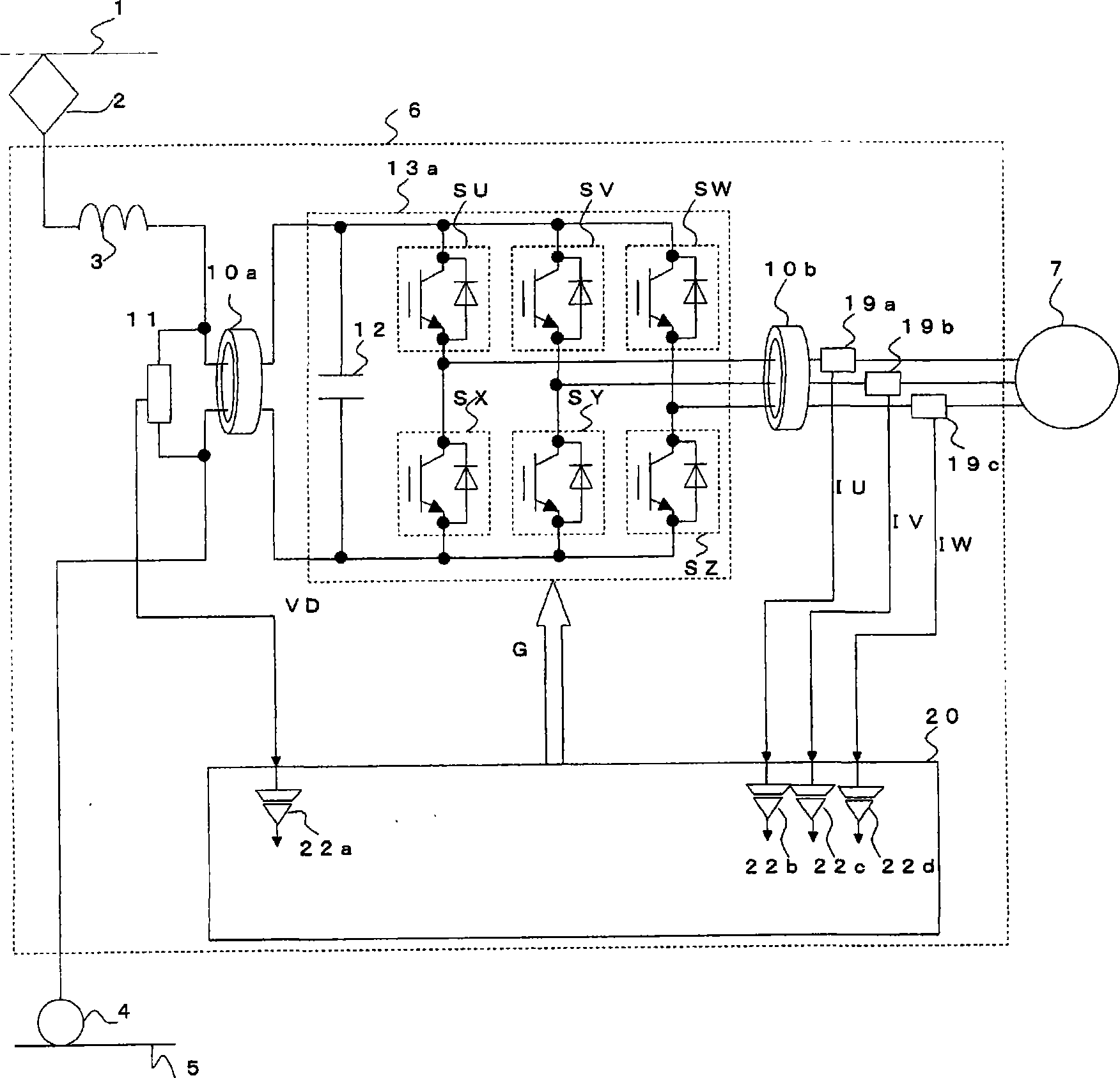

[0050] figure 1 It is a configuration diagram of the power conversion device according to Embodiment 1 of the present invention, and the same reference numerals are assigned to the same or corresponding parts as the technology on which the invention is based.

[0051] In the above-mentioned invention basic technology 1, the voltage detector 11 is connected to the input side conductor of the inverter module 13b on the output side of the first magnetic core 10a, that is, the inverter module 13b side of the first magnetic core 10a, but the present invention In the power conversion device according to Embodiment 1, such as figure 1 As shown, the voltage detector 11 is connected to the input side conductor of the inverter module 13b on the input side of the first magnetic core 10a, that is, on the side opposite to the inverter module 13b side of the first magnetic core 10a. Since the first magnetic core 10a has impedance only to the common mode noise current, even if the voltage d...

Embodiment approach 2

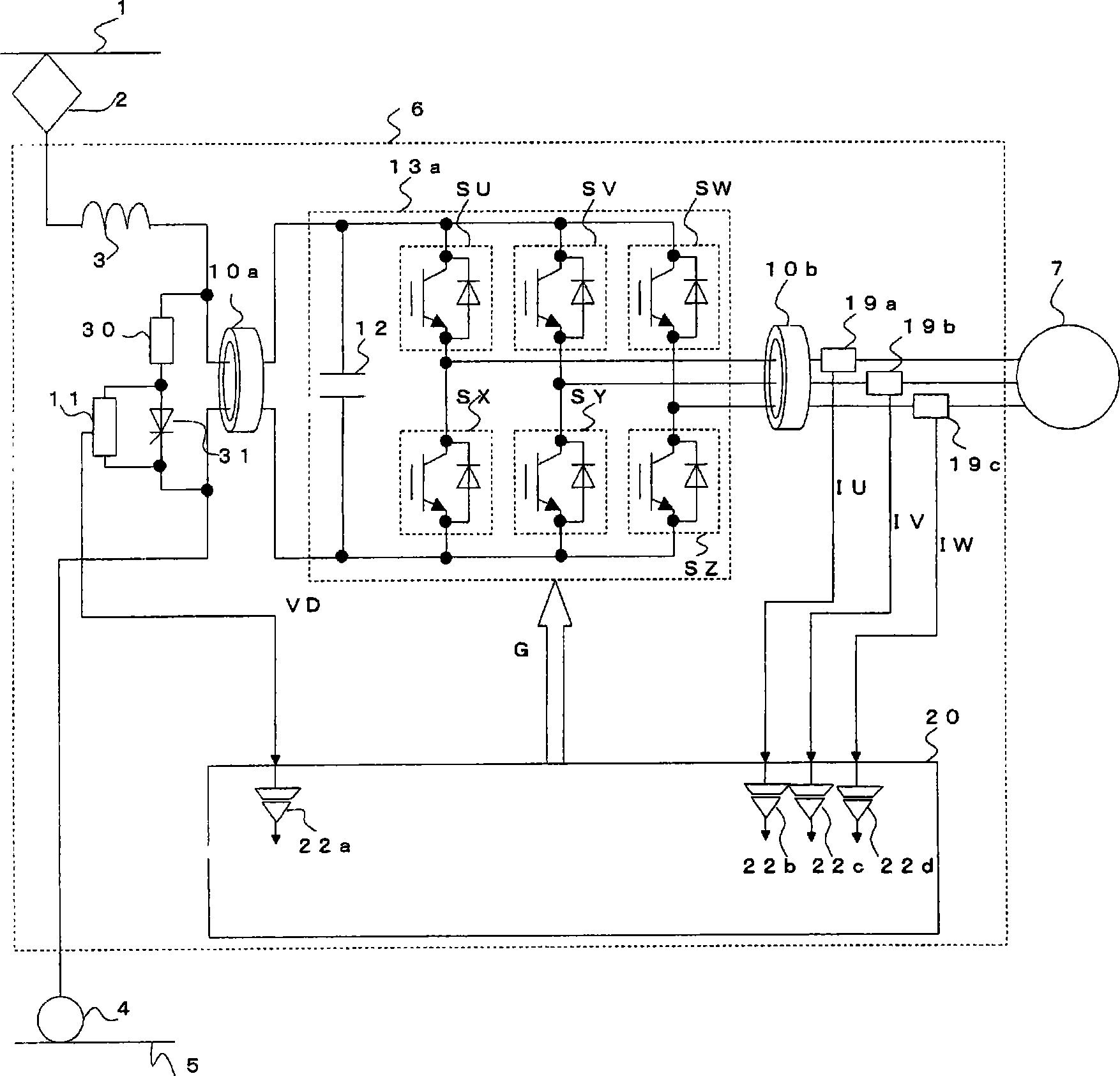

[0057] figure 2 is a configuration diagram of a power conversion device in Embodiment 2 of the present invention, figure 2 Among them, the discharge resistor 30 and the discharge element 31 are connected in series, and they constitute an overvoltage suppression discharge circuit. This overvoltage suppression discharge circuit is connected in parallel with the capacitor 12 . The voltage detector 11 is connected to both ends of the discharge element 31 .

[0058] In the above-mentioned invention basic technology 2, the voltage detector 11 is arranged on the output side of the first magnetic core 10a, but in the power conversion device according to Embodiment 2 of the present invention, as figure 2 As shown, the voltage detector 11 is arranged on the input side of the first magnetic core 10a. Since the first magnetic core 10a has resistance only to the common mode noise current, the voltage across the capacitor 12 can be detected even if the voltage detector 11 is disposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com