Electric spark clearance discharge condition detection apparatus and method based on wavelet transformation

A technology of wavelet transformation and discharge state, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., to achieve high stability and strict timing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

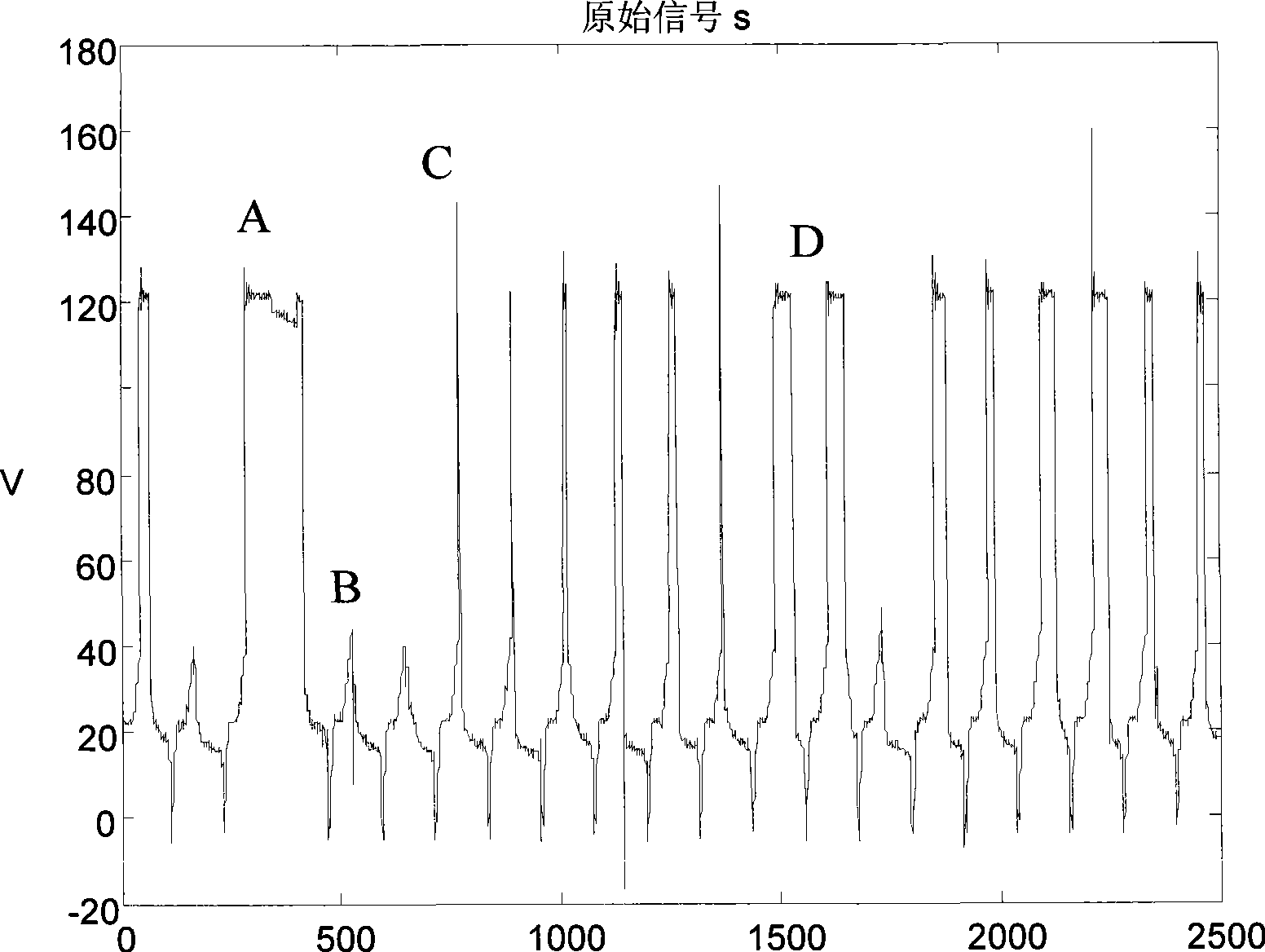

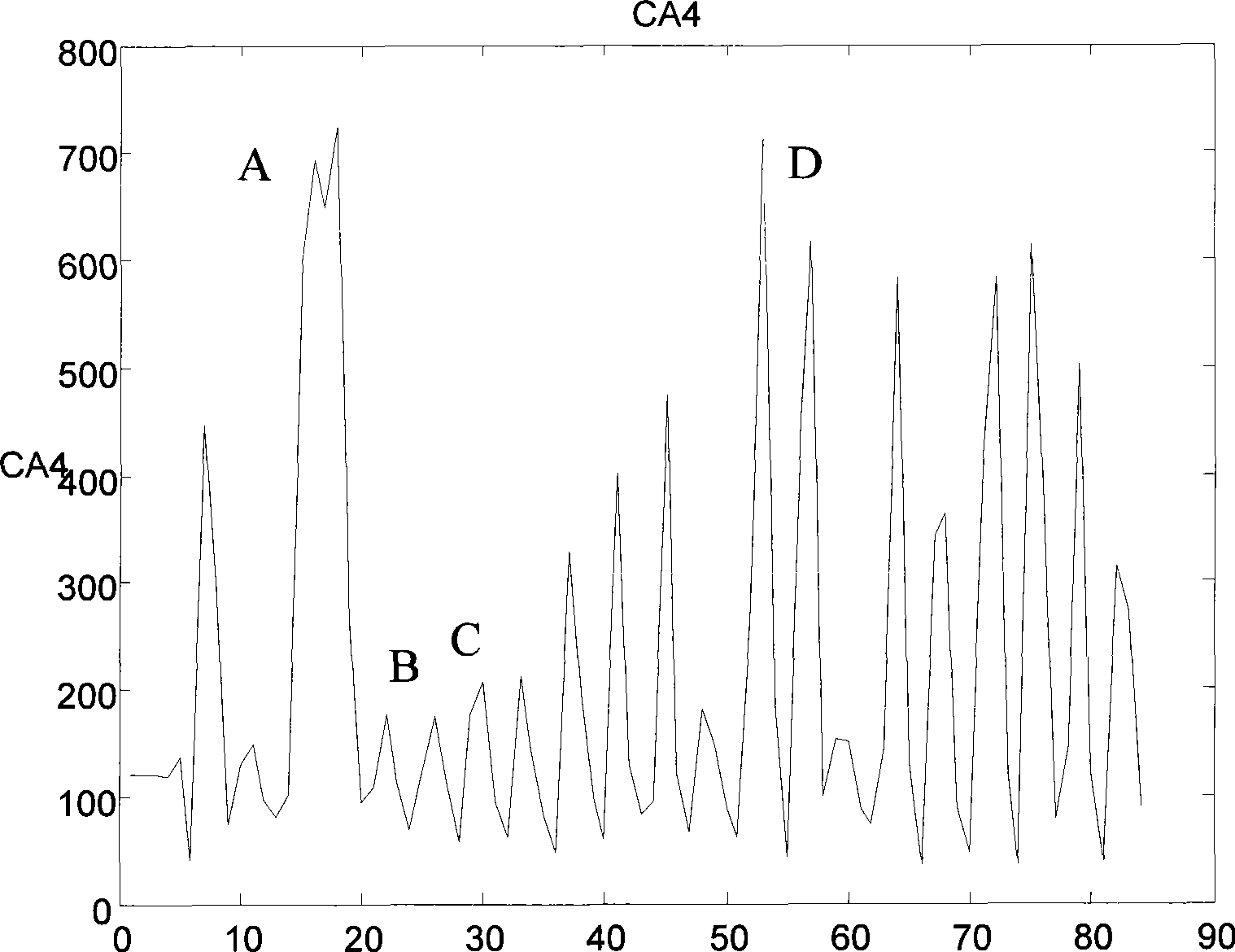

[0062] like figure 2 , 3 shown in figure 2 In the waveform diagram of the original signal s, there is a pulse at A that fails to break down and form a discharge, that is, an "open circuit" pulse appears, and the corresponding image 3 The low-frequency coefficients of CA4 in the fourth layer of wavelet transform results show a large local minimum. figure 2 There are two pulses at middle B that fail to reach the breakdown voltage and discharge first. There is no breakdown delay, and there may be arcing. This is in image 3 There are two small local maxima in . figure 2 There is a pulse with a very small breakdown delay at C in the middle image 3 There is also a correspondingly small local maximum in . figure 2 The two pulses at D in the middle have a larger breakdown delay and are better discharge pulses. They are in image 3 Corresponding to two larger local maxima. It can be seen that the condition of each pulse can be effectively judged by the wavelet transform ...

Embodiment 2

[0069] like Figure 4 and Figure 5 As shown, where the local maximum threshold MAXth=250, the local minimum threshold MINth=350, the total number of pulses Pa=20, the number of partial open pulses Po=1, the number of partial short circuit pulses Ps=12, the discharge state coefficient c=0.45 .

Embodiment 3

[0071] like Figure 6 and Figure 7 As shown, the local maximum threshold MAXth=250, the local minimum threshold MINth=350, the total number of pulses Pa=20, the partial open circuit pulse number Po=8, the partial short circuit pulse number Ps=6, and the discharge state coefficient c=1.10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com