Mechanical arm

A technology of a robot arm and body, applied in the field of robot arms with supporting components, which can solve the problems of insufficient height of the supporting glass substrate, easy wear of the vacuum pad, and increased manufacturing cost, so as to improve convenience, avoid dirt adhesion, and disassembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

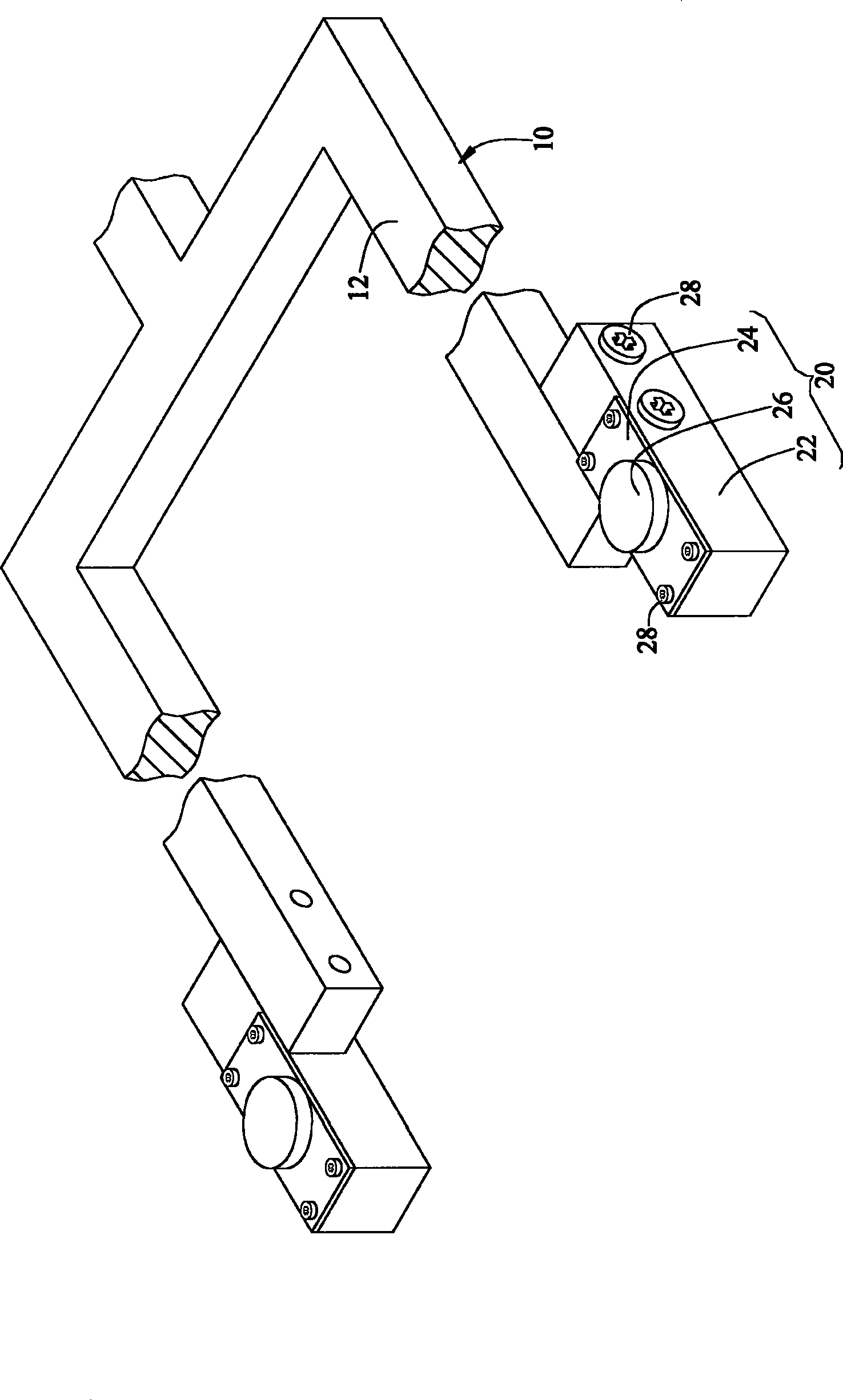

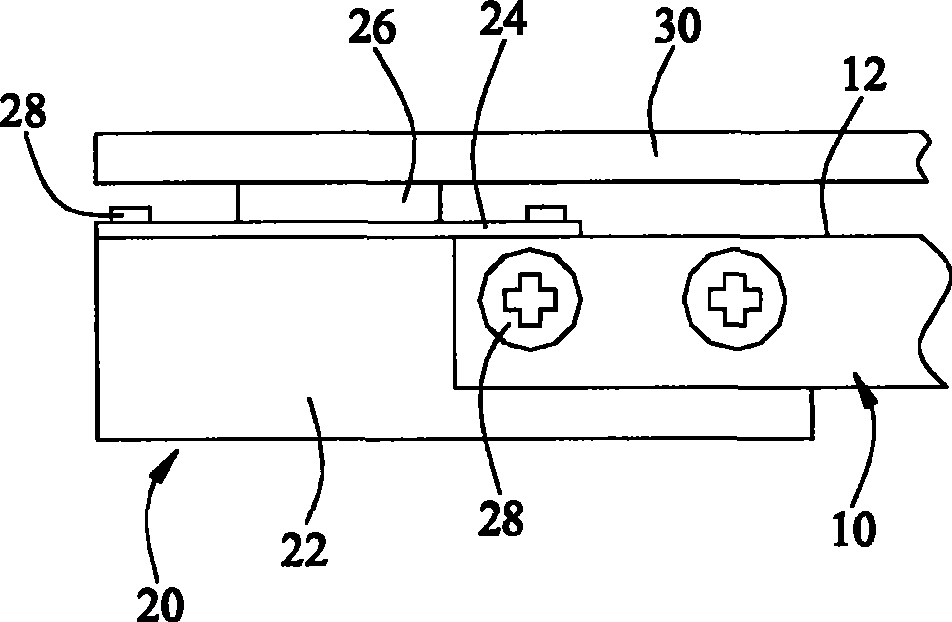

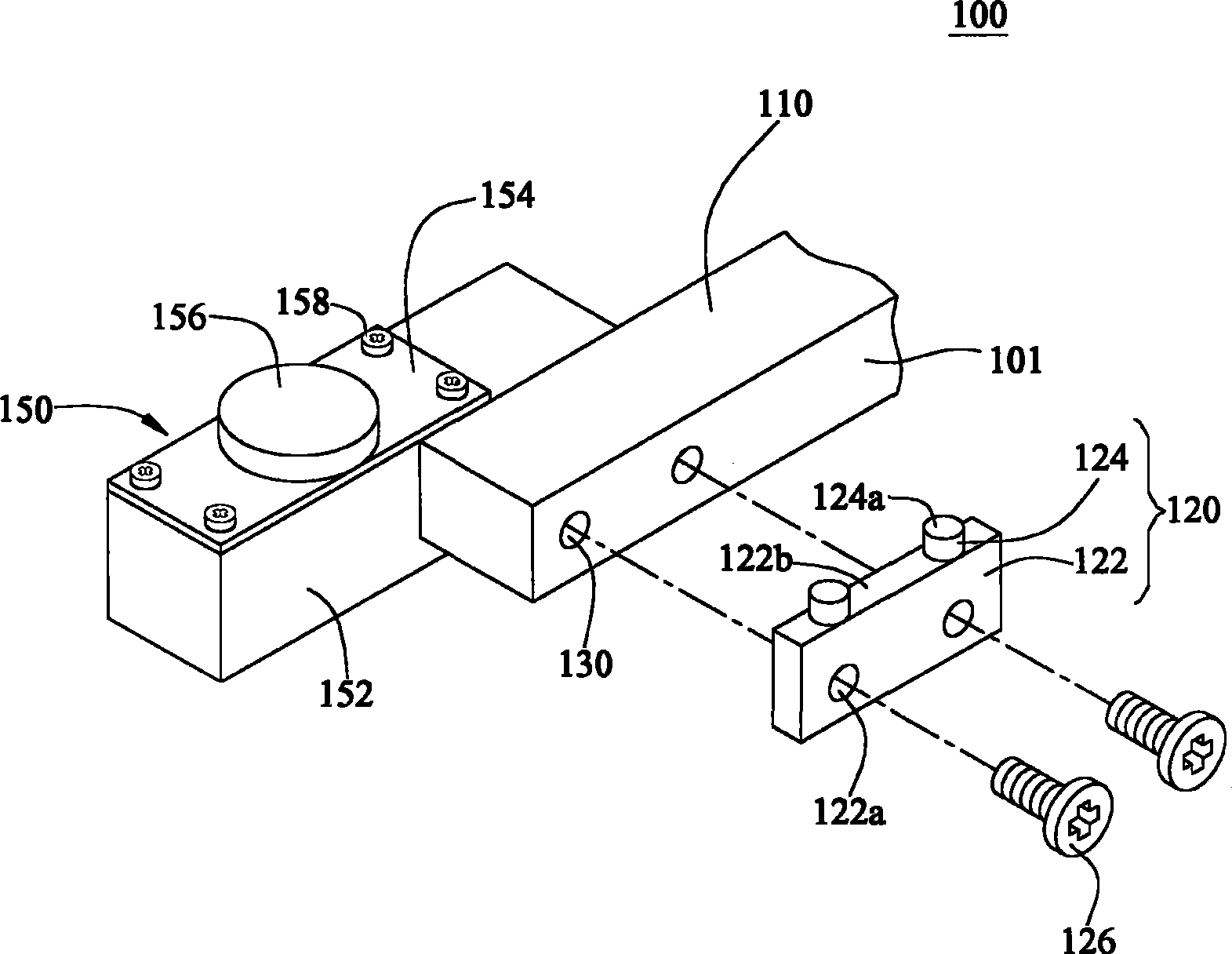

[0031] image 3 It is an exploded schematic diagram of a mechanical arm according to the present invention, Figure 4 for image 3 stereogram of Figure 5 for image 3 side view. see image 3 , Figure 4 and Figure 5 , the robot arm 100 of this embodiment is used to carry a plate 200 . Wherein, the panel 200 disclosed in the present invention can be a fragile electronic semi-finished product such as a glass substrate, a circuit board, a chip, etc., but is not limited thereto. In the following detailed description of the present invention, a glass substrate will be used as a preferred embodiment of the present invention. However, the drawings are only for reference and illustration, and are not intended to limit the protection scope of the present invention.

[0032] The robotic arm 100 includes an arm 101 and a support member 120 , and the upper surface of the arm 101 is a receiving surface 110 . The support member 120 is mounted on one side of the support arm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com