Method for measuring NaNO2 concentration in phosphating solution

A phosphating solution and concentration technology, applied in the field of chemical detection, can solve the problems of inconsistency, reaction, poor repeatability, etc., and achieve the effect of high accuracy and precision and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

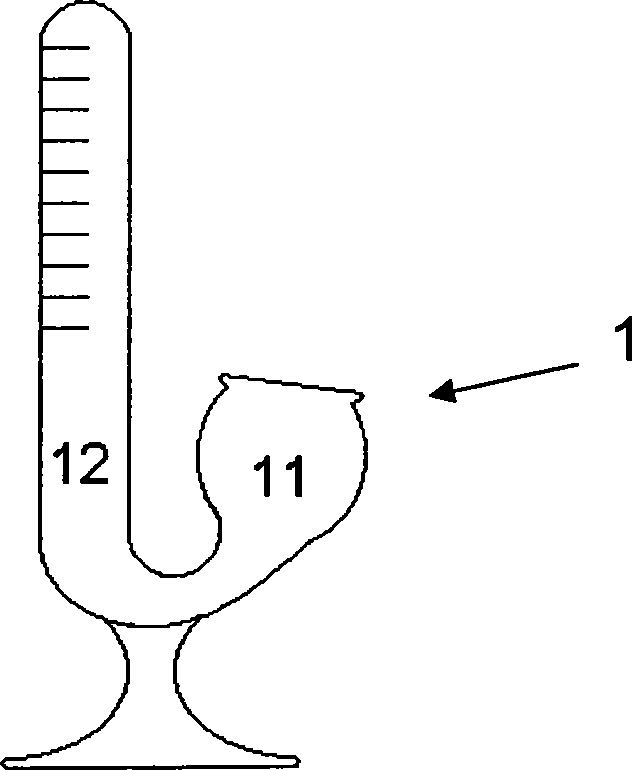

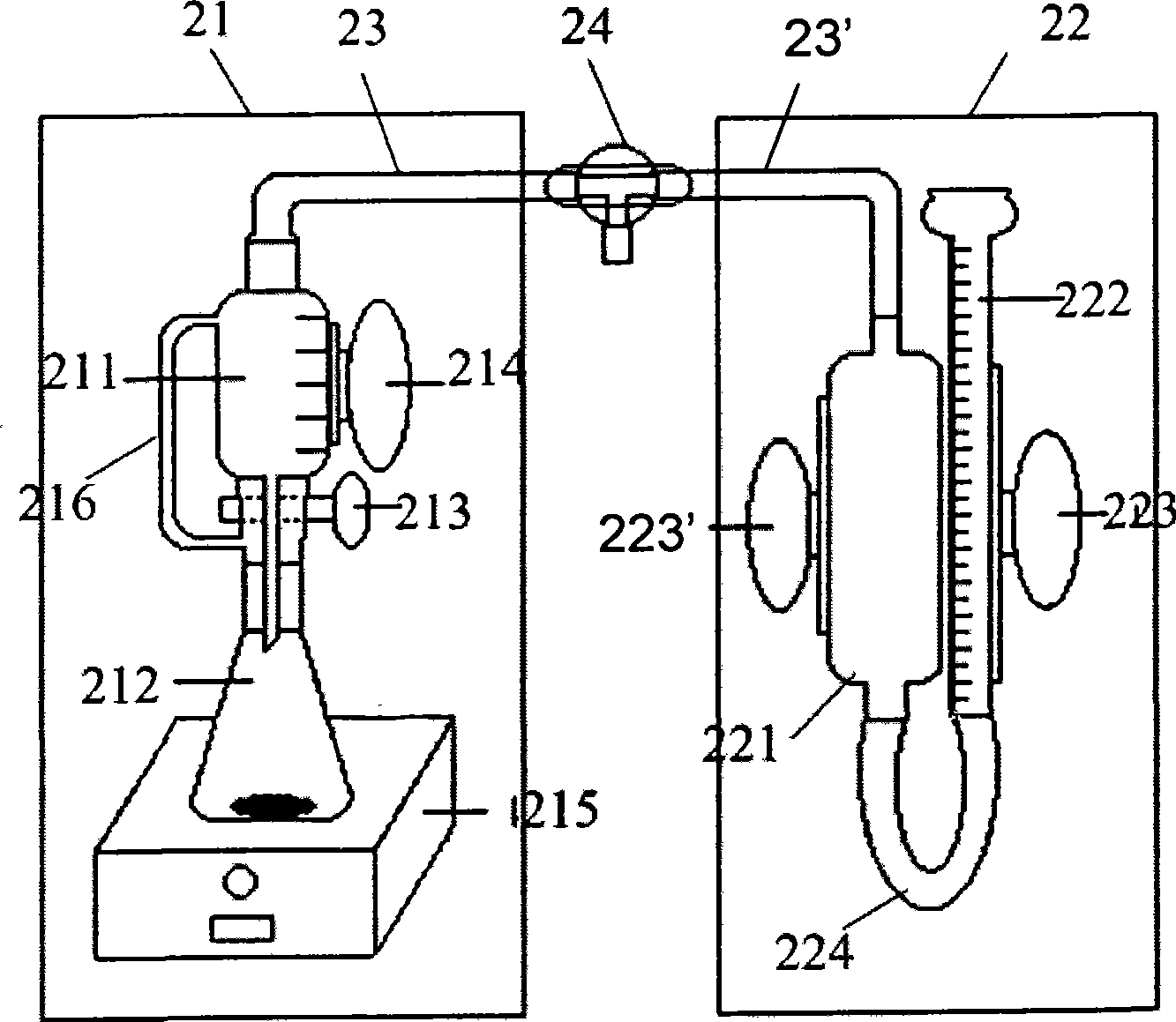

[0046] see figure 2 Determining NaNO in the phosphating solution for the present invention 2 Schematic diagram of the structure of the concentration device, a method for measuring NaNO in phosphating solution 2 The device of concentration comprises a reaction device 21 and a measuring device 22, and the reaction device 21 and the measuring device 22 are respectively connected with the three-way valve 24 through gas pipes 23, 23 ', wherein,

[0047] Described reaction unit 21 comprises:

[0048] A liquid storage pipe 211 is connected with the three-way valve 24 through the gas pipe 23, and the bottom of the liquid storage pipe 211 is connected with a dropper 213 with a switch,

[0049] A sample bottle 212 is placed below the liquid storage tube 211. The thin tube 217 of the liquid storage tube 211 is passed into the sample bottle 212. The opening of the sample bottle 212 is sealed. upper unicom,

[0050] An adjustment knob 214, located at the liquid storage pipe 211, to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com