Micro-inertial sensor with variable pitch capacitor and method for producing the same

A technology of micro-inertial sensor and spacing, which is applied in chemical instruments and methods, components of TV systems, piezoelectric/electrostrictive/magnetostrictive devices, etc. Increase the mechanical noise of the sensor, the large air damping of the laminated film, etc., to achieve the effect of novel structure, reducing air damping, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is by no means limited to the described embodiments.

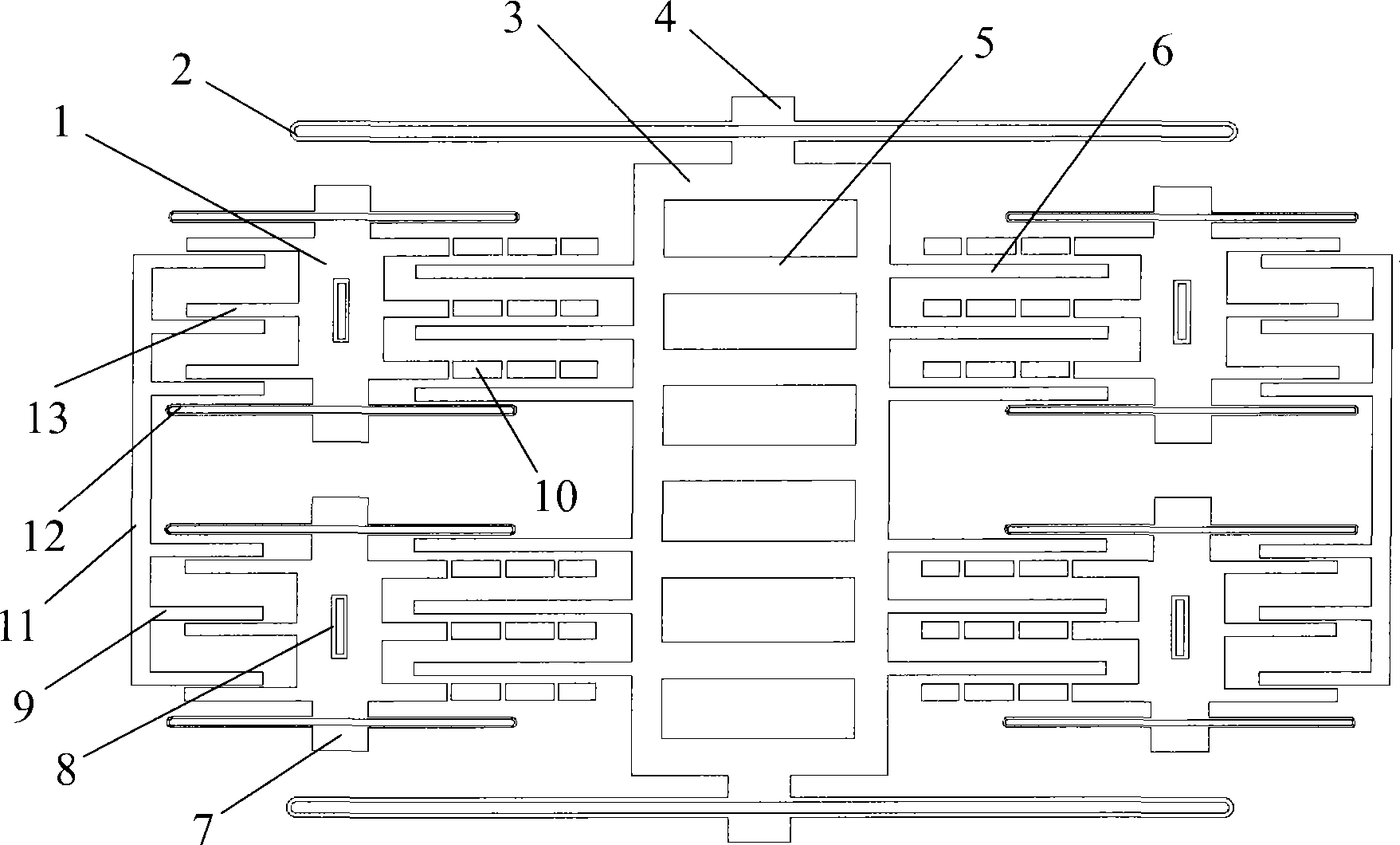

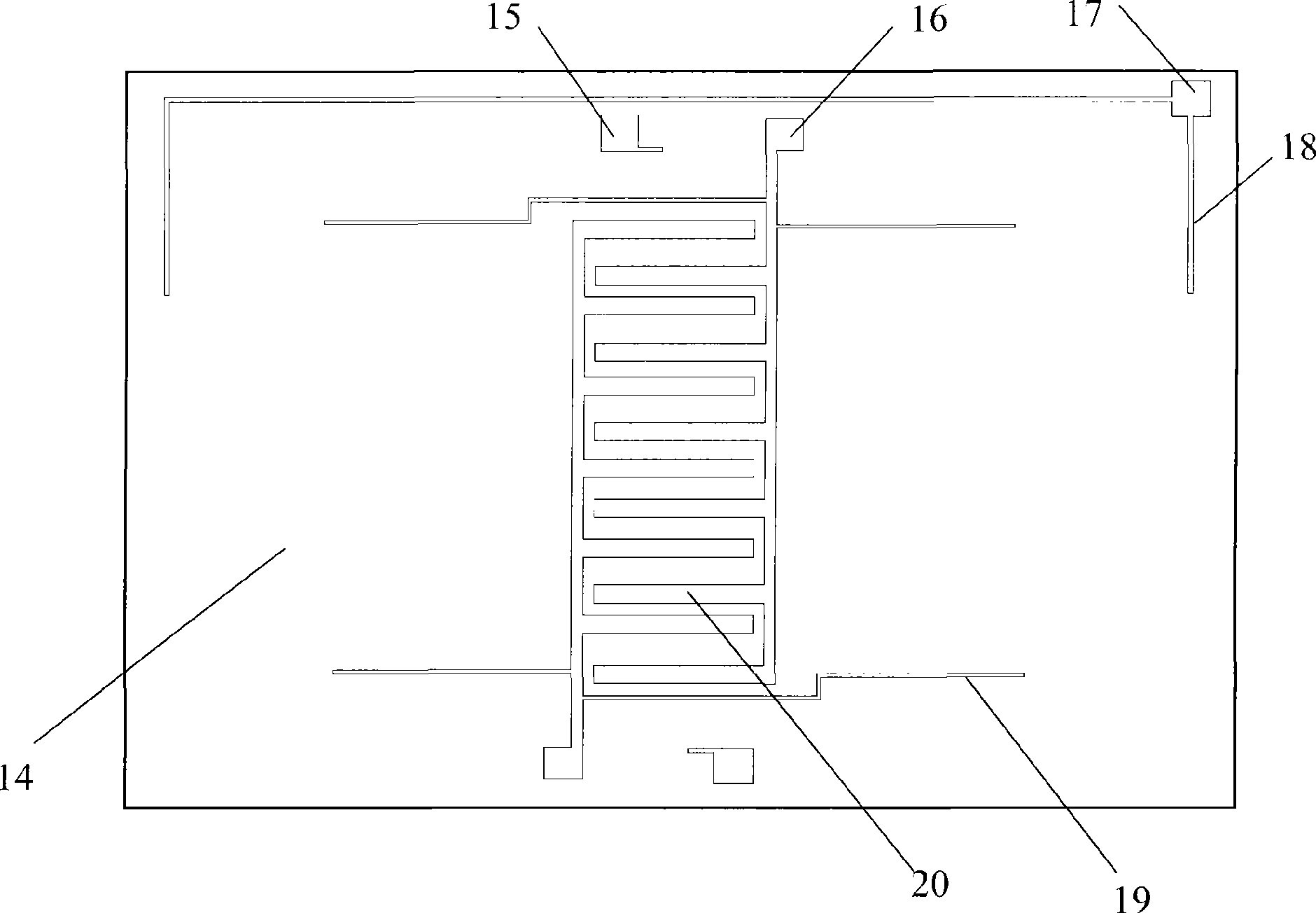

[0023] Such as figure 1 , 2 As shown in and 3, a micro-inertial sensor with variable pitch capacitance includes a glass substrate 14, a sensor mass 3, a driver mass 1 and a fixed driving silicon strip 11.

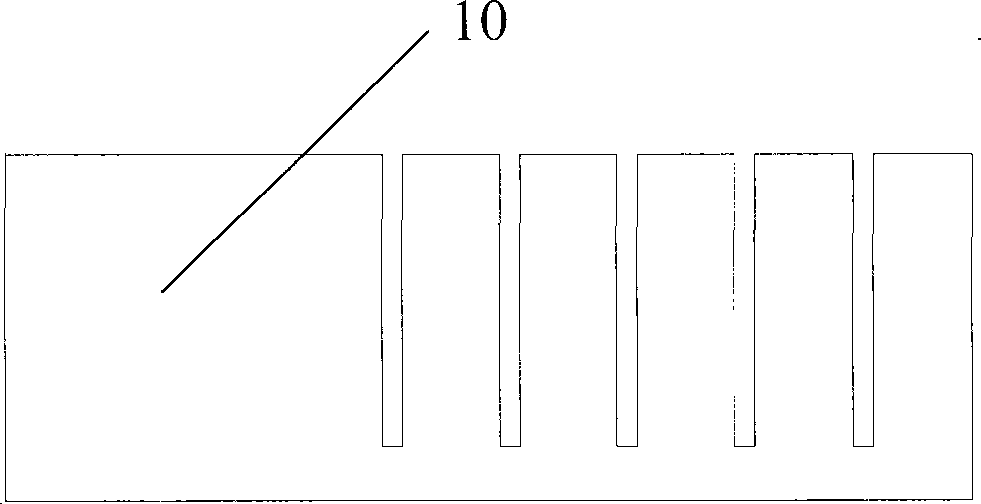

[0024] The sensor mass 3 is a rectangular silicon wafer, and the two corresponding ends of the sensor mass 3 are connected to the sensor anchor point 4 through the sensor U-shaped silicon support beam 2, and the sensor anchor point 4 is fixedly arranged on the glass substrate 14, The sensor mass 3 is arranged in parallel with the glass substrate 14; the other two corresponding ends of the sensor mass 3 are respectively provided with two groups of silicon strip groups, and each group of silicon strip groups includes three silicon strips 6 arranged in parallel, and the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com