Micro inertial sensor embedded with movable electrode and manufacturing method thereof

A micro-inertial sensor and moving electrode technology, which is applied in the field of micro-inertial sensors, can solve the problems of increasing the mass of the sensor vibrator, reducing the distance between the plates, increasing the mechanical noise of the sensor, and large air damping of the film, achieving novel structure and reduced pressure. Small air damping, the effect of reducing mechanical noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

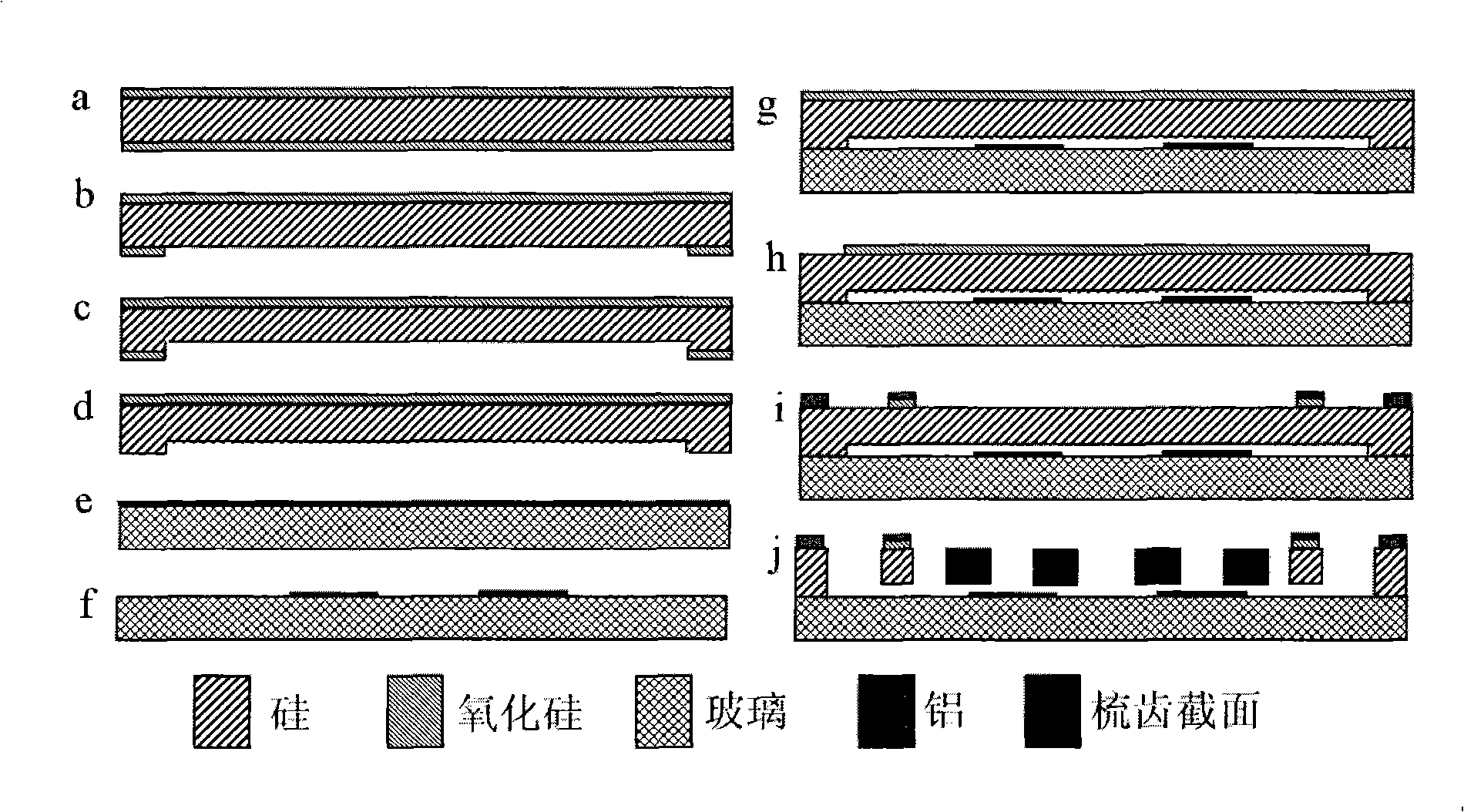

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is by no means limited to the described embodiments.

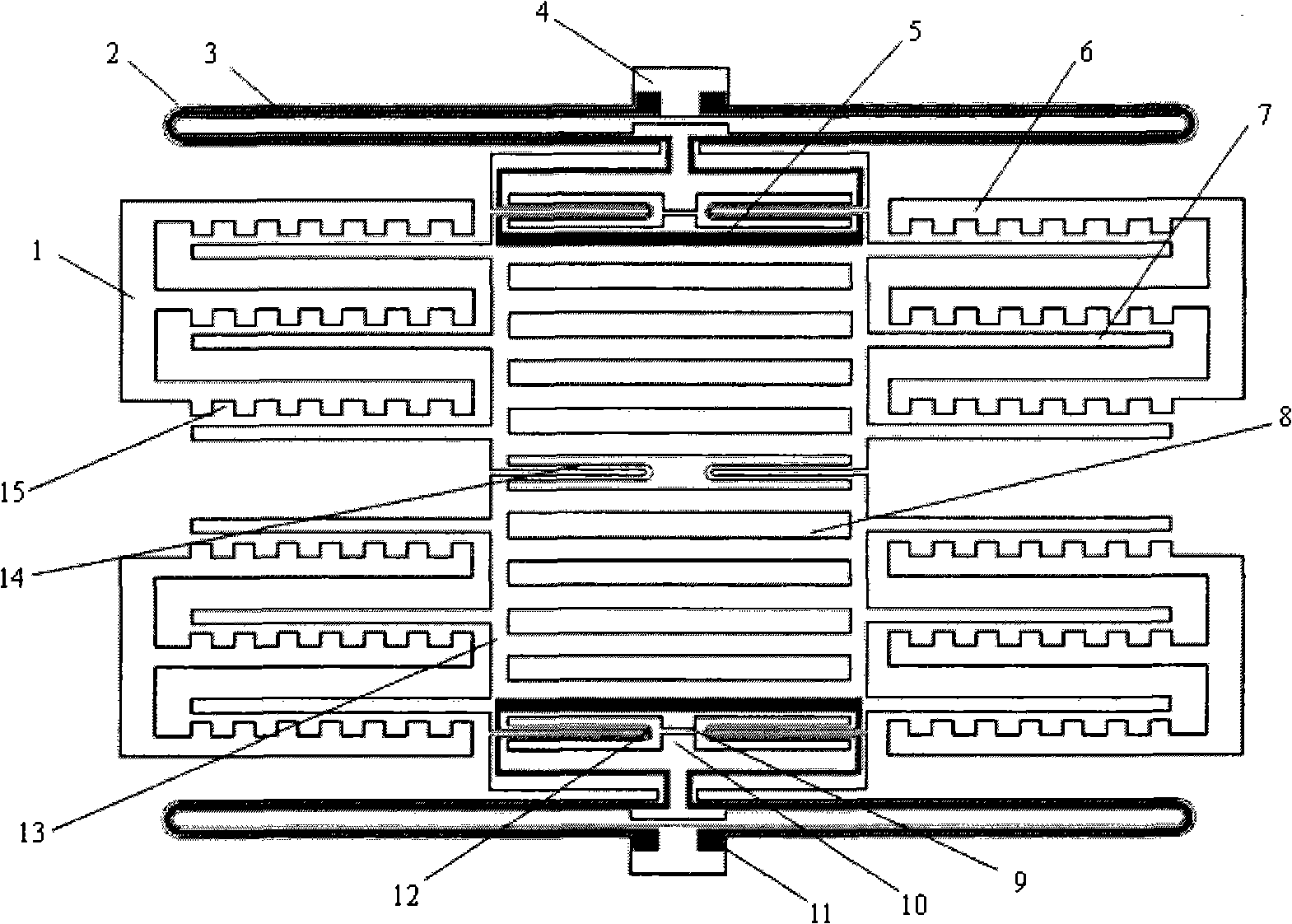

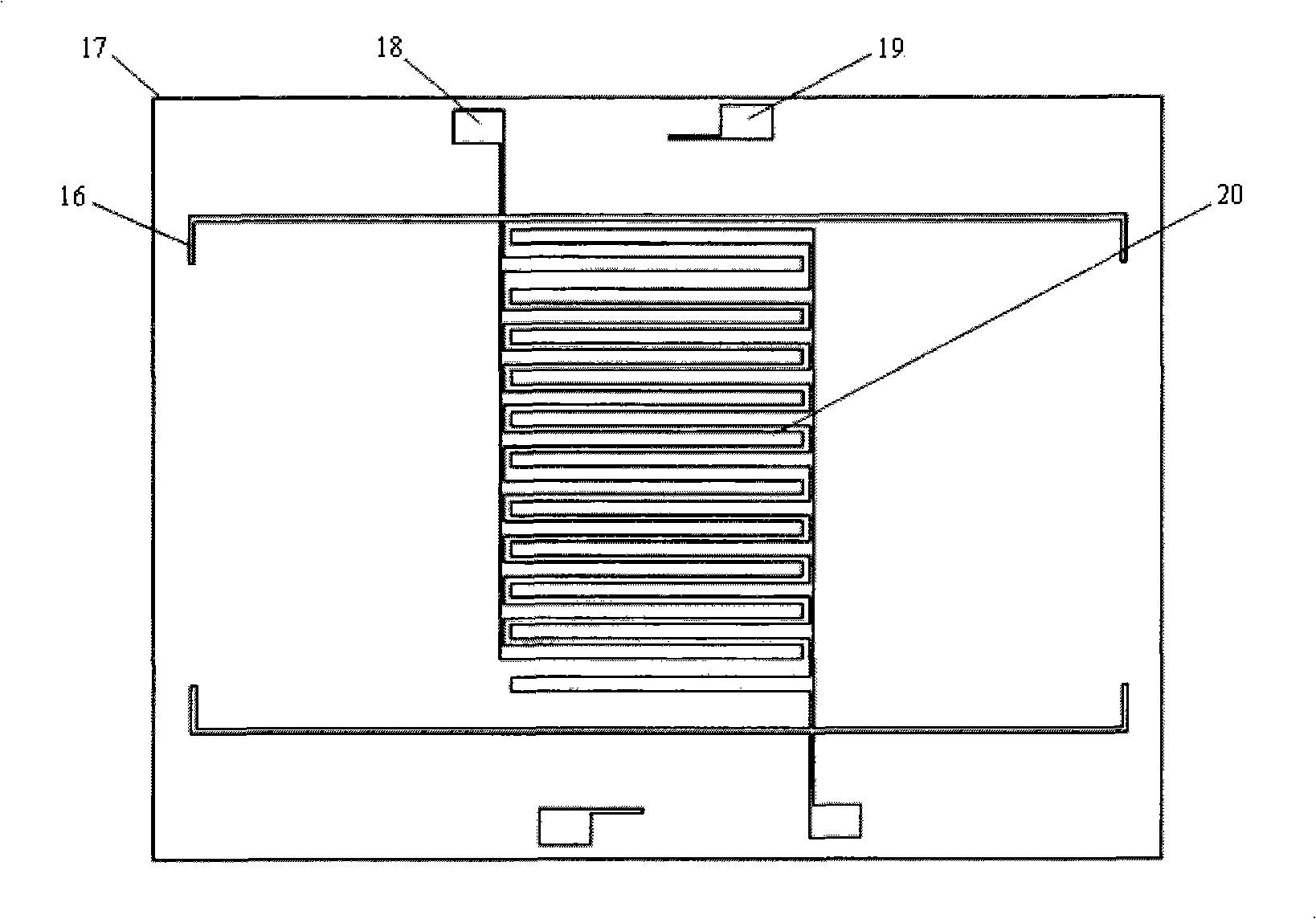

[0025] like figure 1 and figure 2 As shown, a micro inertial sensor embedded with movable electrodes includes a glass substrate 17 , a movable sensor mass, and four fixed masses 1 .

[0026] The movable sensor mass is rectangular, and three pairs of through-slots 14 are symmetrically opened from the edge of the movable sensor-mass to the center, wherein one pair of through-slots 14 is located in the middle of the movable sensor mass, and the other two pairs are respectively located near At the positions of the two ends of the movable sensor mass, three pairs of through grooves divide the movable sensor mass into four parts, namely two fixed parts 10 at both ends and two movable parts 13 in the middle. The two fixed parts 10 of the movable sensor mass block are connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com