Self-heat preserving building block of exterior wall

A technology for self-insulating blocks and exterior walls, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Material cost, effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

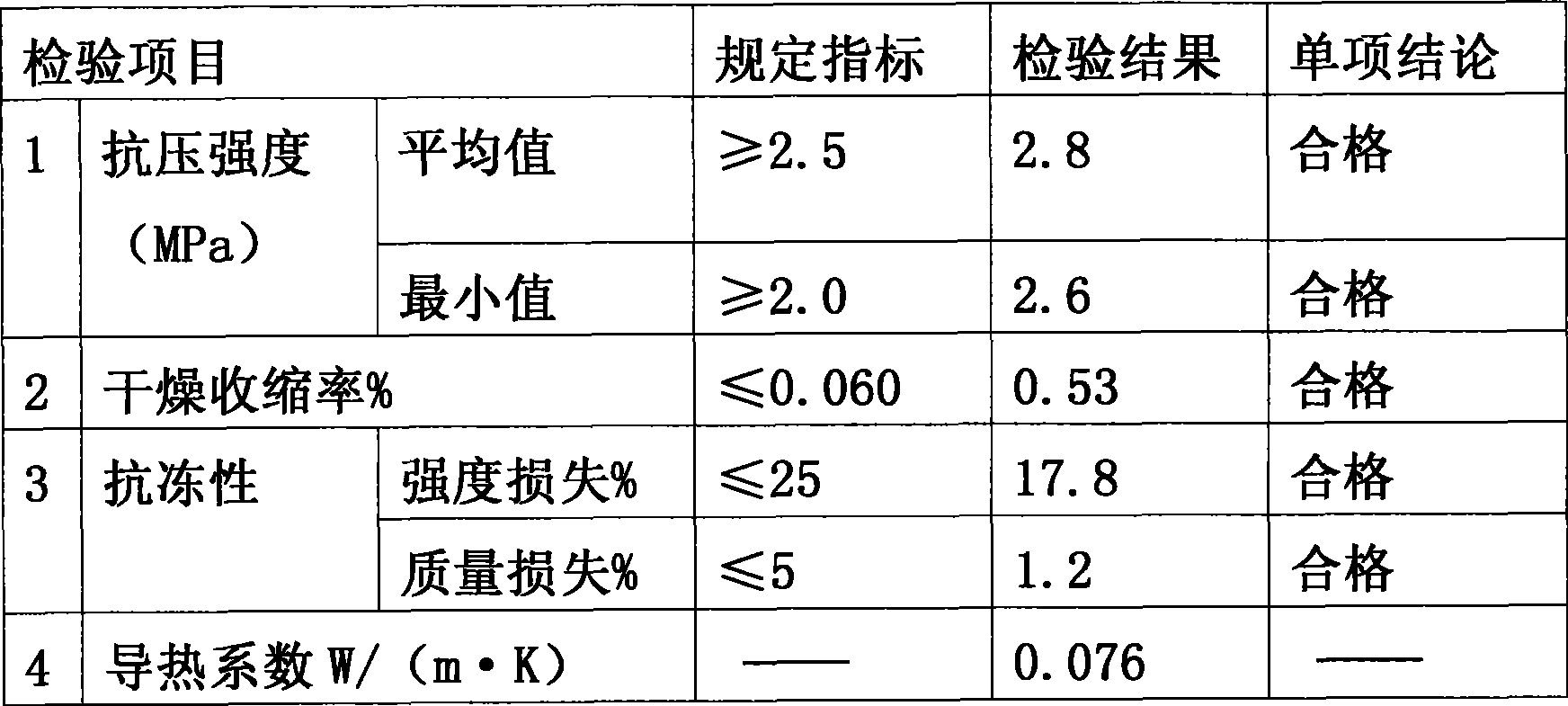

Embodiment 1

[0017] The proportioning by weight of this example raw material component is as follows:

[0018] Steel-making high-temperature furnace waste slag fiber cotton: 5 parts,

[0019] Silica fume: 1.5 parts

[0020] Natural pumice wool: 2 parts

[0021] Cement: 2 parts.

[0022] The waste slag fiber cotton of the steelmaking high-temperature furnace is a kind of waste slag flowing out from the high-temperature furnace, and its bulk density is required to be 600 kg / m 3 The following is to ensure the lightness of this raw material; the silica fume is a kind of dust recovered from industries such as metallurgy, and it is required that the silicon dioxide contained in the silica fume should be more than 70%, and its bulk density should be 280 kg / m 3 Hereinafter, to ensure the thermal insulation performance and light weight of this raw material; the natural pumice velvet is natural pozzolan, which is available in the market; any cement sold in the market can be used for cement. Then...

Embodiment 2

[0024] The proportioning by weight of this example raw material component is as follows:

[0025] Steelmaking high-temperature furnace waste slag fiber cotton: 4 parts,

[0026] Silica fume: 2 parts

[0027] Natural pumice wool: 3 parts

[0028] Cement: 2 parts.

[0029] Material selection principle and making are identical with embodiment 1.

Embodiment 3

[0031] The proportioning by weight of this example raw material component is as follows:

[0032] Steelmaking high-temperature furnace waste slag fiber cotton: 4.5 parts,

[0033] Silica fume: 1.8 parts

[0034] Natural pumice wool: 2.5 parts

[0035] Cement: 1.8 parts.

[0036] Material selection principle and making are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com