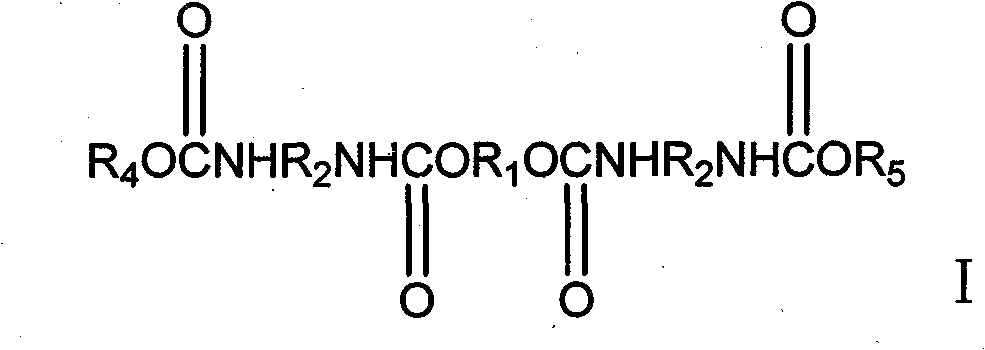

Light-sensitive self-initiated polyurethane acrylic ester oligomer and method for synthesizing the same

A urethane acrylate and self-initiating technology is applied in the field of urethane acrylate oligomer mixture and preparation, which can solve the problems of non-substitution and achieve the effects of reducing toxicity, simplifying formulation process and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

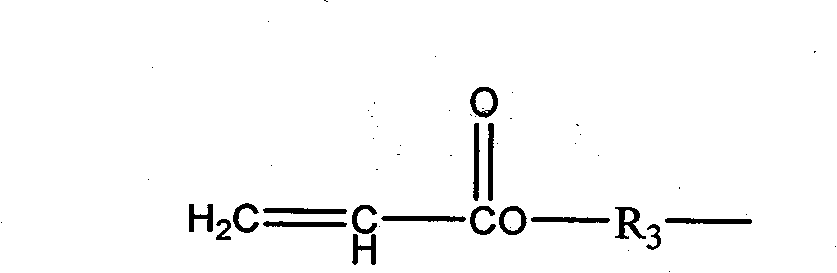

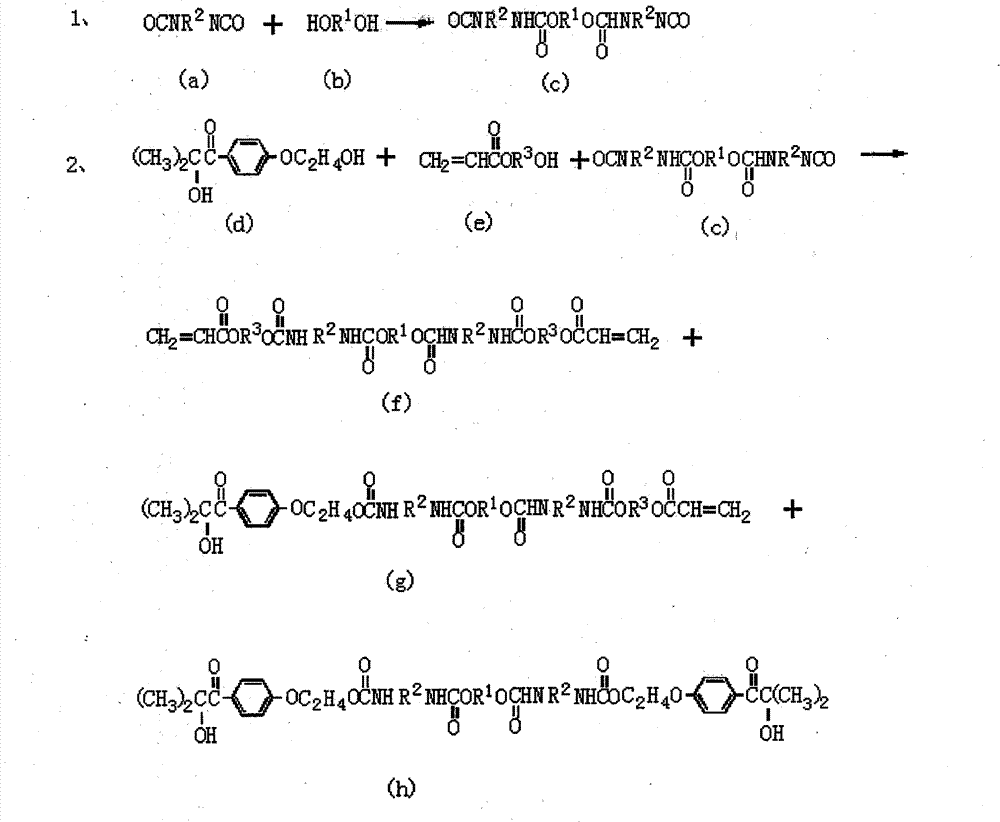

Method used

Image

Examples

Embodiment 1

[0034] In a 3000ml reaction flask equipped with a thermometer, a stirrer, a dropping funnel, a condenser and a nitrogen inlet, add 400g of polyethylene glycol 400, then raise the temperature to 80°C, feed nitrogen throughout the reaction process, and drop 348g of toluene di The mixture of isocyanate (TDI) and 0.5% catalyst dibutyltin dilaurate, after reacting for 2 hours, raise the material temperature to 90°C and continue the reaction for 2 hours, stop the reaction, lower the system to room temperature, seal the reactor with black material, and heat up To 70°C, add a total of 90g of photoinitiator UV2959 (dissolved in 400g of ethyl acetate), continue the reaction for 1 hour after the addition, then add 186g of hydroxyethyl acrylate dropwise, continue the reaction for a certain period of time, and test with an infrared spectrometer The content of the isocyanate group in the reaction solution is until the absorption peak of this group disappears, the net solvent is vacuumed off,...

Embodiment 2

[0036] The material obtained in Example 1 is mixed with tripropylene glycol diacrylate in a ratio of 1:1

[0037] (DPGDA) mixed, coated on a glass plate to form a 0.1mm liquid film, irradiated with a high-pressure mercury lamp, and the liquid film can be polymerized and solidified without adding a photoinitiator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com