Anti-cracking adhesive for energy-saving lamp and preparation thereof

A technology for energy-saving lamps and adhesives, applied in the direction of monocarboxylic acid ester copolymer adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of poor adhesion, easy loosening, and low environmental protection. problems, to achieve the effect of moderate cost, environmentally friendly life, and low packaging requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] In the stirring mixer, add 10kgA-9841 polyvinyl acetate emulsion, then add 0.1kg defoamer, 1kg deionized water, start stirring for ten minutes until the stirring is uniform, slowly add 3kg titanium dioxide R-930, 17kg 800-mesh heavy calcium, 0.33kg polypropylene fiber, 10g isothiazolinone, 10g anti-aging agent 2246, after adding, continue to stir and mix for 2 hours. At this time, the material is a white paste-like viscous liquid. When no sagging is detected by a sag tester and at the same time it has a certain fluidity, the stirring can be stopped and the material is packaged.

[0015] The adhesive for energy-saving lamps prepared by the formula has high cost performance, is easy to glue, and has a smooth surface.

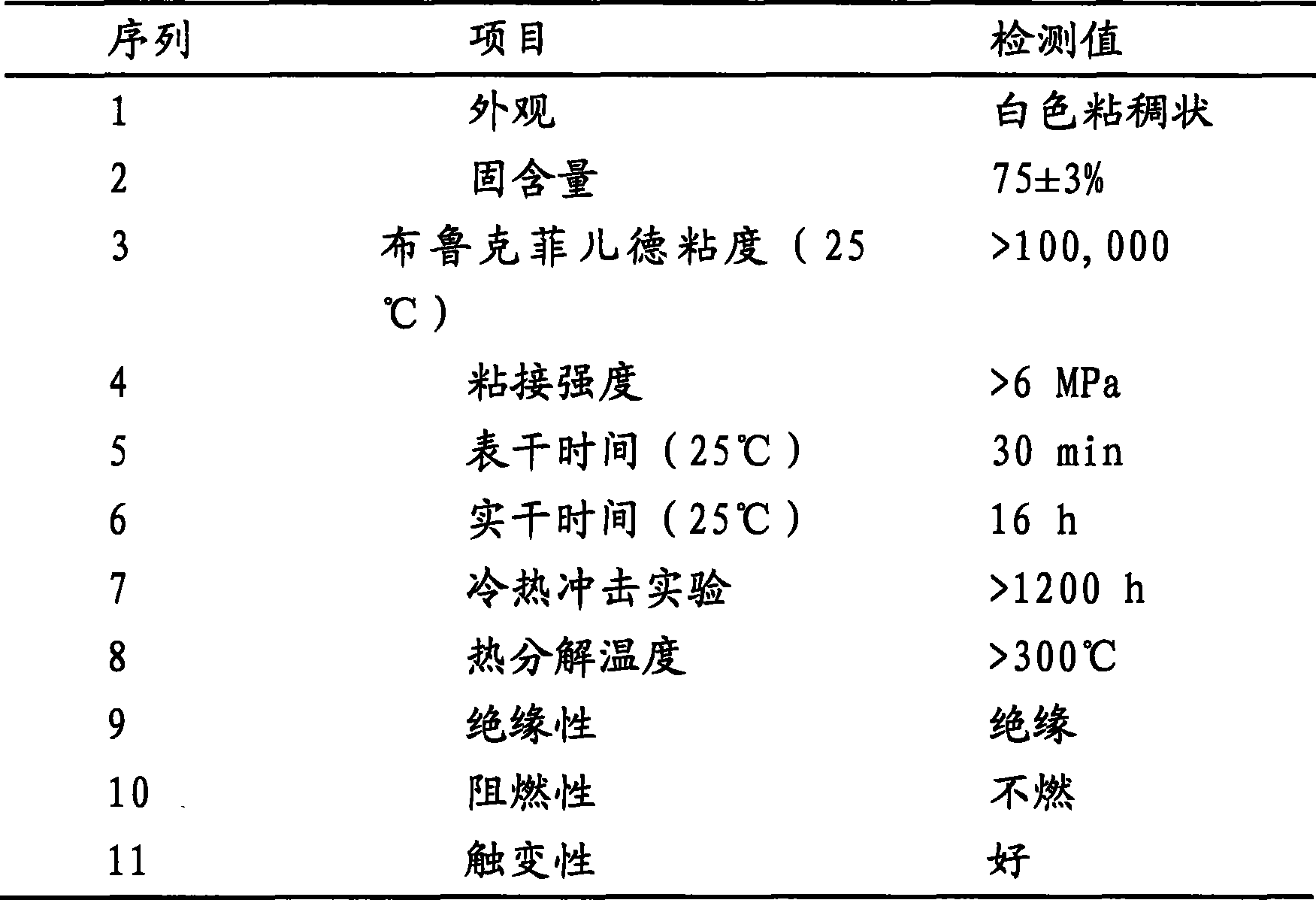

[0016] As an example, the main performance indicators of the anti-cracking adhesive for energy-saving lamps made by the present invention are as follows:

[0017] Product main performance indicators

[0018]

Embodiment 2

[0020] In the stirring mixer, add 10kg D-68M styrene-acrylic emulsion, then add 0.1kg defoamer, 1kg deionized water, start stirring for ten minutes until the stirring is uniform, slowly add 6kg titanium dioxide R930, 6kg 800 Mesh calcined kaolin, 8kg 800mesh talcum powder, 0.33kg polyacrylonitrile fiber, 10g isothiazolinone, 10g anti-aging agent 2246, continue stirring and mixing for 2 hours after adding, the material is a white paste-like viscous liquid at this time. When no sagging is detected by a sag tester and at the same time it has a certain fluidity, the stirring can be stopped and the material is packaged.

[0021] The adhesive for energy-saving lamps prepared by the formula has strong adhesion.

Embodiment 3

[0023] In the stirring mixer, add 10kgCP-149 polyvinyl acetate-ethylene copolymer emulsion, then add 0.1kg defoamer, 1kg deionized water, start stirring for ten minutes until the stirring is uniform, slowly add 6kg titanium dioxide, 14kg 800-mesh silica powder, 0.33kg lignin fiber, 10g isothiazolinone, 10g anti-aging agent 2246, after adding, continue to stir and mix for 2 hours. At this time, the material is a white paste-like viscous liquid. When no sagging is detected by a sag tester and at the same time it has a certain fluidity, the stirring can be stopped and the material is packaged.

[0024] The energy-saving lamp adhesive prepared by the formula has good toughness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com