Thyristor electronic board for failure current limiter

A thyristor electronic board and fault current technology, applied in the field of power systems, can solve problems such as poor anti-interference ability, monitoring signal transmission, and increased leakage reactance, and achieve strong anti-electromagnetic interference ability, strong anti-interference ability, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

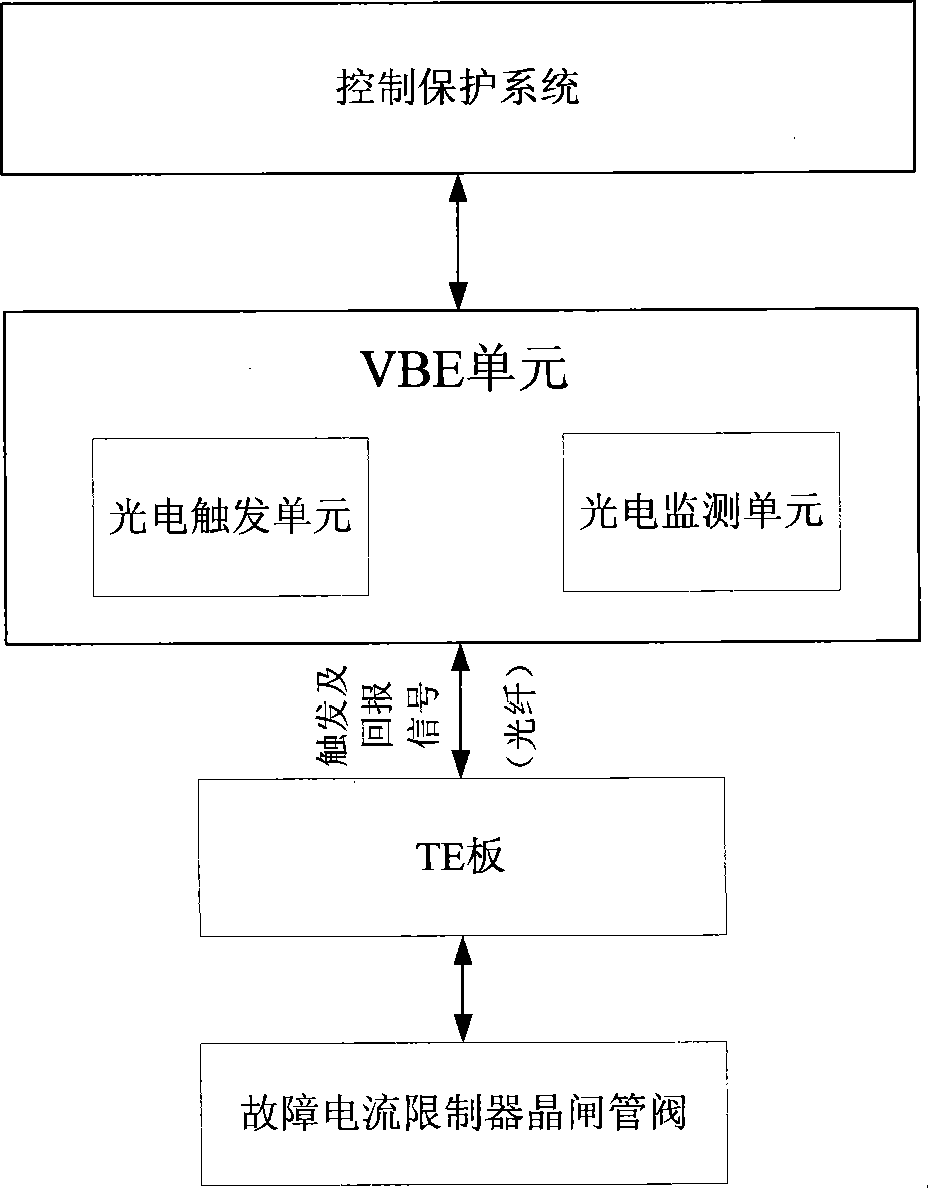

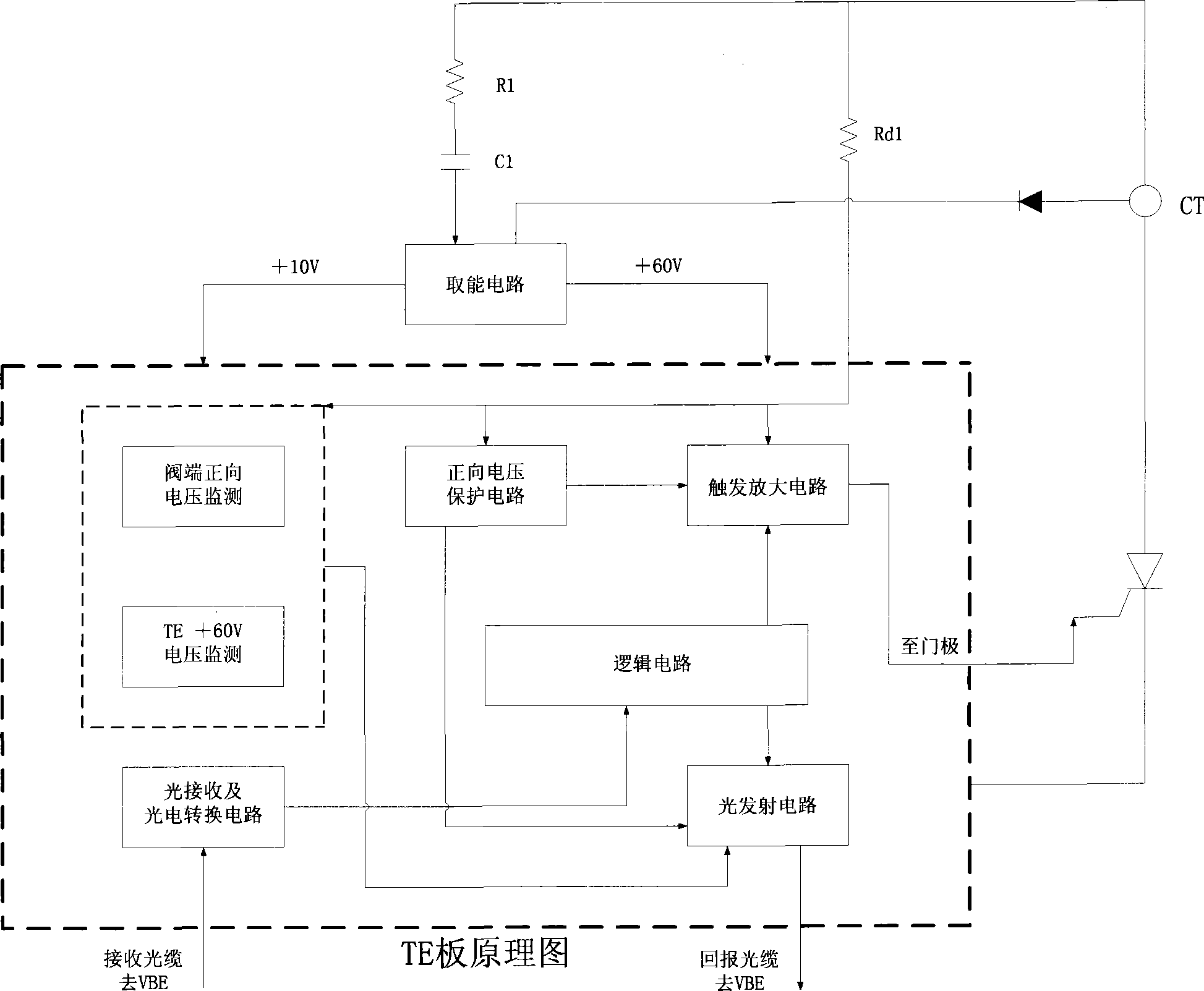

[0027] Thyristor electronic board TE principle as technical attachment image 3 . The technical solution is as follows:

[0028] (1) Thyristor triggering and online monitoring

[0029] The fault current limiter is put into operation only when the transmission line is short-circuited, so the fault current limiter is in the waiting state for a long time. In order to ensure the reliable operation of the fault current limiter, the thyristor electronic board TE monitors the state of the thyristor in real time during the waiting state and thyristor electronic board TE's own power supply status, determined by the attached image 3 Middle valve terminal voltage monitoring and thyristor electronic board TE+60V power supply monitoring circuit are realized. Each cycle is 20ms. The valve-based electronic equipment VBE sends monitoring pulses to the thyristor electronic board TE through a high-voltage optical cable. After passing through the light receiving and photoelectric conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com