Radiation type heating board structure for electronic product annealing and sintering furnace

A technology of electronic products and radiant panels, which is applied in the direction of furnace heating elements, lighting and heating equipment, furnaces, etc., can solve the problems of unfavorable annealing or sintering, unevenness, etc., and achieve the effects of uniform temperature, uniform heating, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

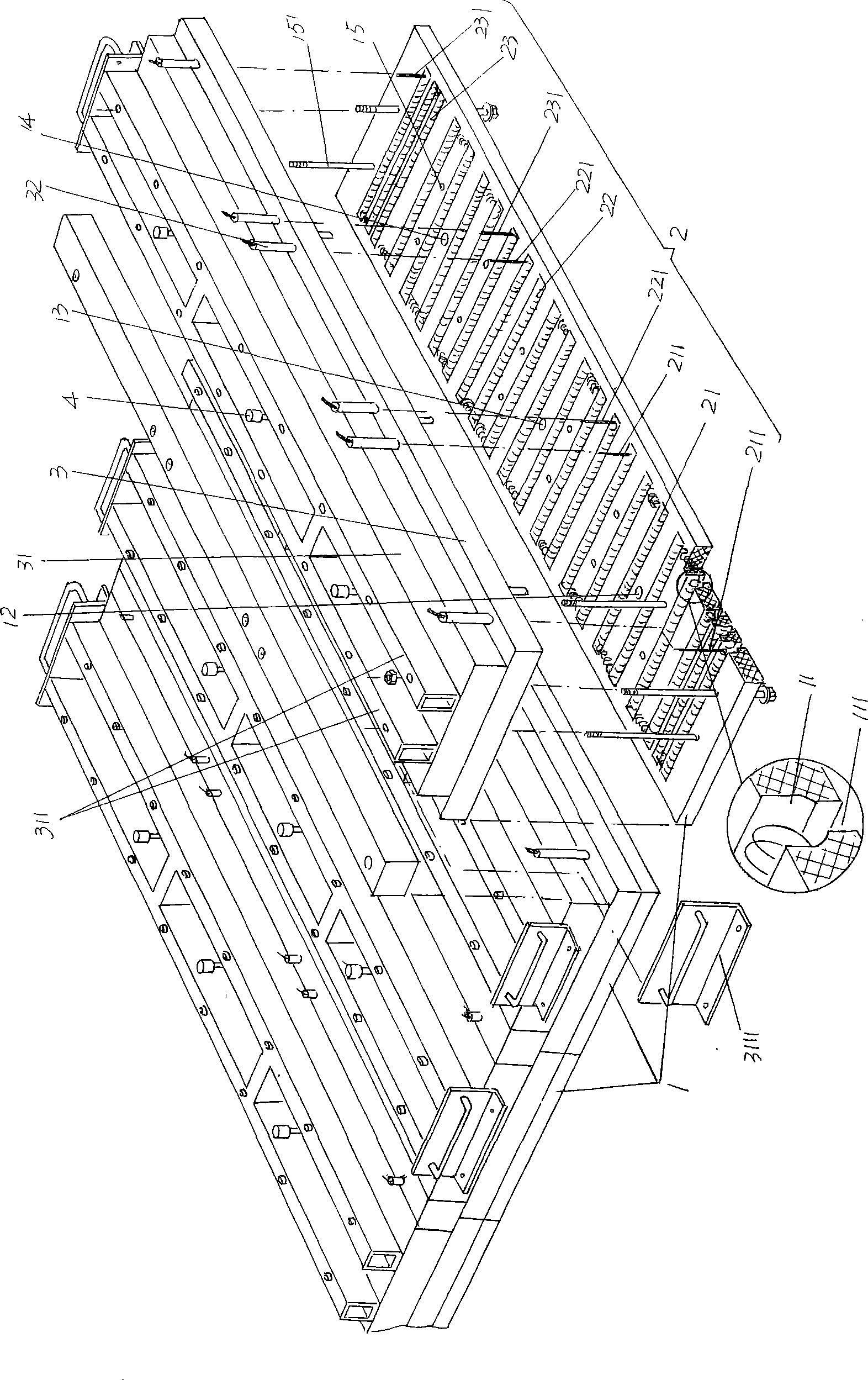

[0021] See figure 1 According to common knowledge, the length of the furnace body of an annealing and sintering furnace for electronic products is long or short, ranging from several meters to tens of meters, and ranging from tens to hundreds of meters. Therefore, the radiant panel body 1 has a width determined The number of cases also changes accordingly. Since the structure of each radiant panel body 1 provided by the technical solution of the present invention is the same, although five are shown in the figure, the applicant chooses one to describe in detail below. description of.

[0022] The radiant panel body 1 is made of ceramic fiber board, and the radiant panel body 1 is provided with electric heating wire slots 11, wherein the electric heating wire slots 11 located at the left and right ends of the radiant panel body 1 The spacing is smaller than the spacing of the electric heating wire slots 11 at other positions. In this embodiment, the electric heating wire slot...

Embodiment 2

[0026] The figure is omitted, the electric heating wire slot 11 is processed into a U shape, and the notch 111 in Embodiment 1 is omitted. This solution can prevent the oxidation of the first, second, and third electric heating wires 21, 22, and 23 surfaces. Objects fall into the furnace to pollute the product, and the furnace is kept clean. All the other are the same as the description to embodiment 1.

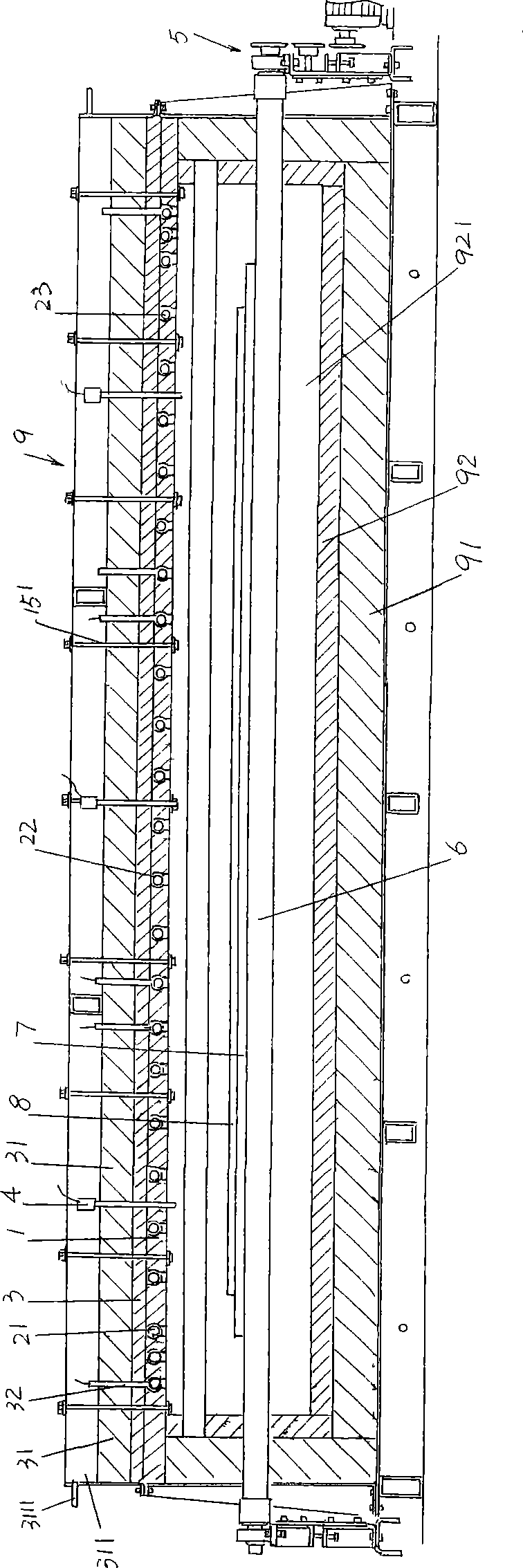

[0027] please see figure 2 , this figure has provided the sectional shape of the body of furnace 9 of electronic product annealing furnace or sintering furnace, and the interior of body of furnace heat insulating layer 91 is furnace 92, and the conveying roller 6 in the hearth 921 of furnace 92 is provided with supporting plate 7 Place the plasma display panel 8 as an electronic product on the supporting plate 7, and the radiant panel body 1 of the present invention is fixed on the furnace hearth 921 top of the body of heater 9 by a group of bolts 151 carrying the insulatio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap