Method for preparing carboneous solid acid catalyst

A solid acid catalyst and carbon-based technology, which is applied in the preparation of solid acid catalysts and carbon-based solid acid catalysts, can solve the problems of sulfonated sulfonic acid groups, etc., and achieve reduced corrosion, safe reaction process, and low raw material prices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

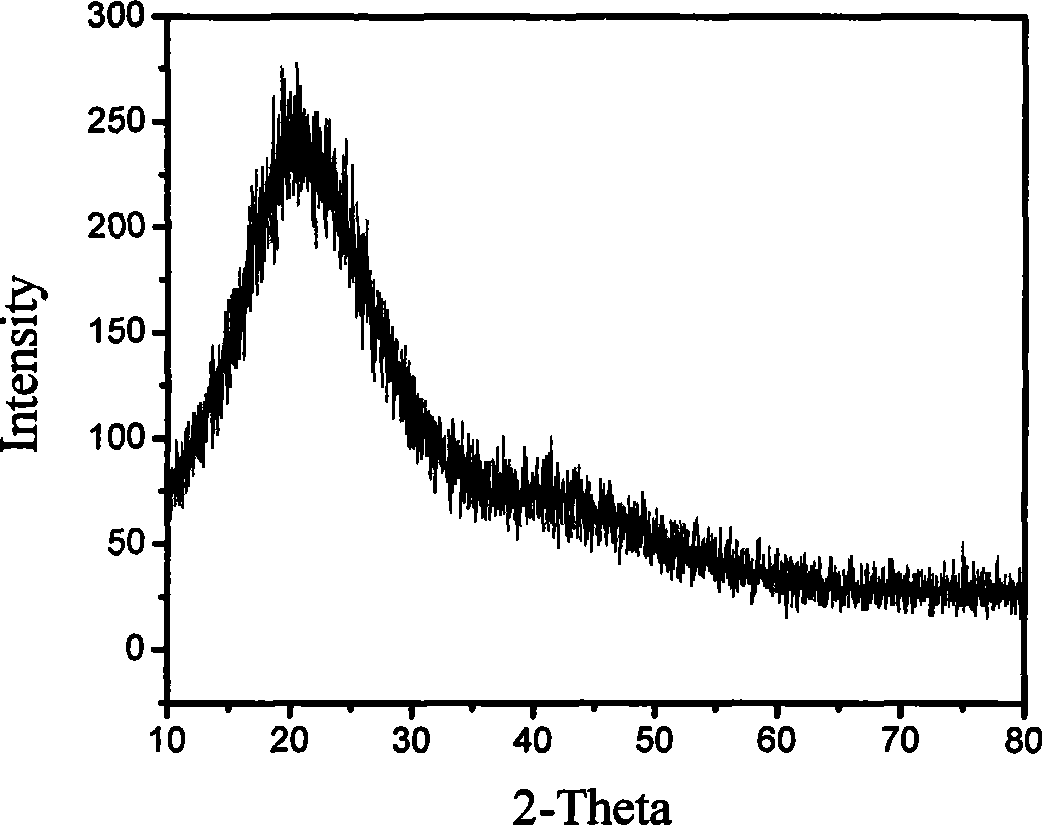

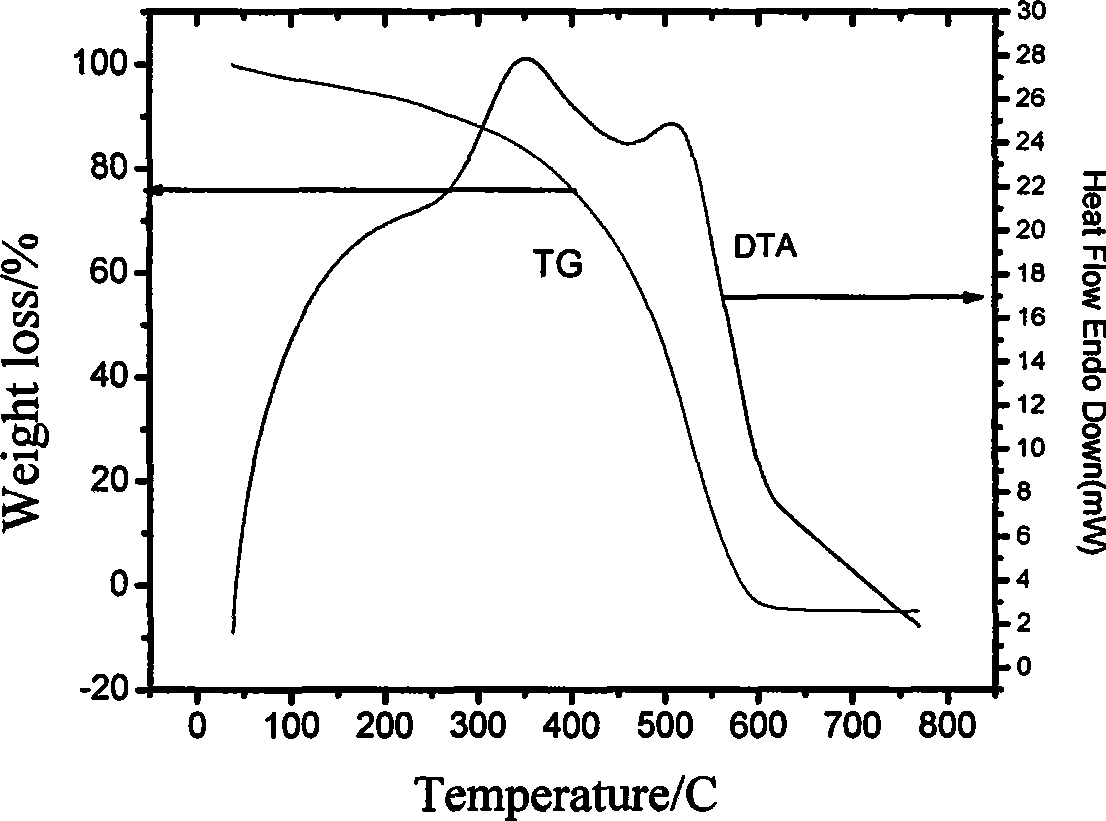

Embodiment 1

[0017] Weigh 2.021g of glucose and 2.077g of sulfosalicylic acid, add a certain amount of ethanol, stir to make them evenly mixed, place them in a stainless steel autoclave lined with polytetrafluoroethylene, and react in an oven at 180°C for 24 hours. Take it out and cool it, wash it with deionized water and ethanol, and filter it, and dry the obtained product overnight at 90°C. The surface acid content measured by acid-base titration was 1.2 mmol / g.

Embodiment 2

[0019] Weigh 2.085g of sucrose and 3.104g of sulfosalicylic acid, add a certain amount of ethanol, stir to make them evenly mixed, place them in a stainless steel autoclave lined with polytetrafluoroethylene, and react in an oven at 180°C for 24 hours. Take it out and cool it, wash it with deionized water and ethanol and filter it, and dry the obtained product overnight at 90°C. The surface acid content measured by acid-base titration was 1.1 mmol / g.

Embodiment 3

[0021] Weigh 2.090g of glucose and 2.164g of p-toluenesulfonic acid, add a certain amount of ethanol, stir to make them evenly mixed, place them in a stainless steel autoclave lined with polytetrafluoroethylene, and react in an oven at 180°C for 24 hours. Take it out and cool it, wash it with deionized water and ethanol and filter it, and dry the obtained product overnight at 90°C. The surface acid content measured by acid-base titration is 1.5 mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com