Continuous casting tundish stopper

A technology of stopper rod and continuous casting, which is used in foundry equipment, casting melt containers, manufacturing tools, etc., can solve the problems of slag corrosion and fracture of stopper rods and slag lines, and breakage of stopper rods. Cost consumption, the effect of avoiding the accident of broken rod and pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

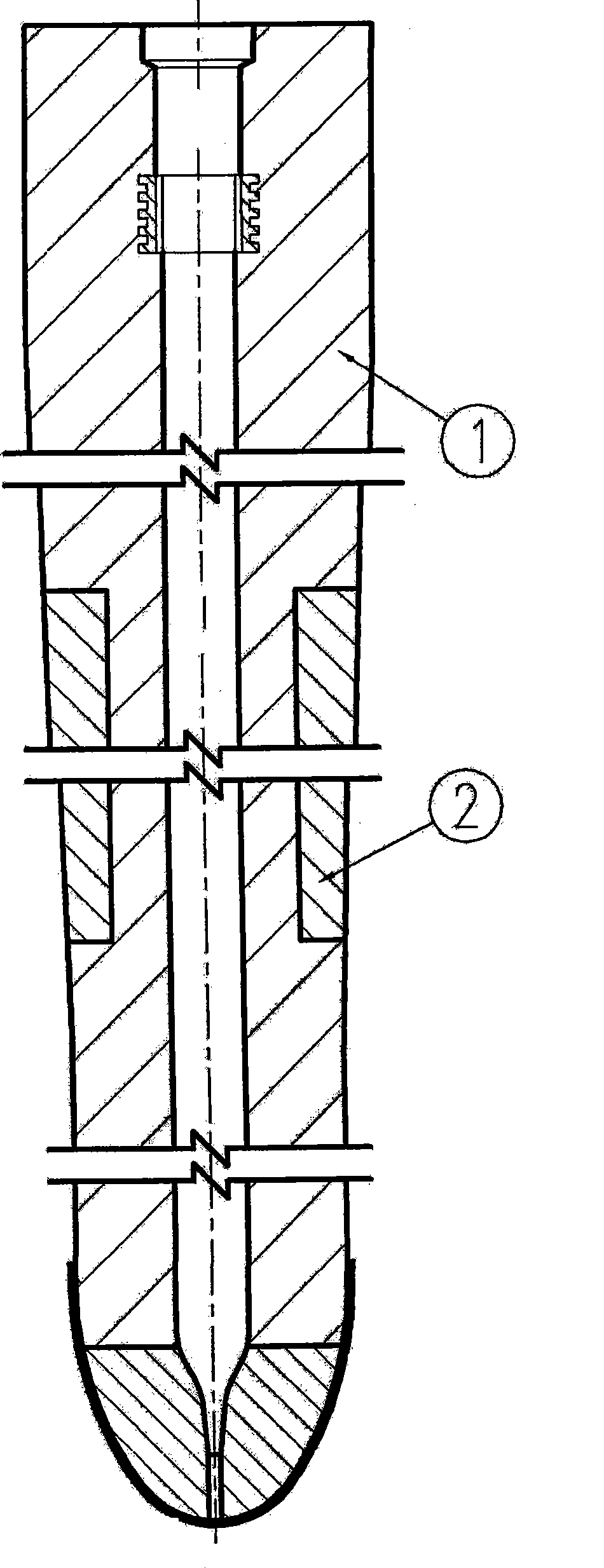

[0013] Referring to the accompanying drawings, the long-life continuous casting tundish stopper includes a stopper body 1 and a stopper slag line 2 .

[0014] 1. The composition and physical and chemical properties of refractory materials at the slag line are shown in the following table:

[0015] List of main components of refractories at the slag line

[0016] name symbol unit Example 1 Example 2 Example 3 silica SiO 2 % 9 13 10.18 Aluminum oxide al 2 o 3 % 0.6 0.8 0.65 iron oxide Fe 2 o 3 % 0.3 0.4 0.27 Calcium Oxide CaO % 3 2 1.33 magnesium oxide MgO % 0.1 0.25 0.15 Zirconia ZrO 2 % 63 61.55 61.90 graphite C % 24 22 25.52

[0017] Table of physical indicators of refractories at the slag line

[0018] name unit skills requirement typical value Tensile modulus: N / mm 2 8.6~9.3 9.1 Surface porosity: % 11.5~16.0 13.8 Bulk density: g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com