Cutterhead apparatus for automatic cutting machine

A technology of cutting machine and cutter head, which is applied in the cutting, application, leather punching/punching/cutting of textile materials, etc. It can solve the problems of cutter breaking, affecting work efficiency, and not being able to maintain the cutter, so as to increase the service life , improve production efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

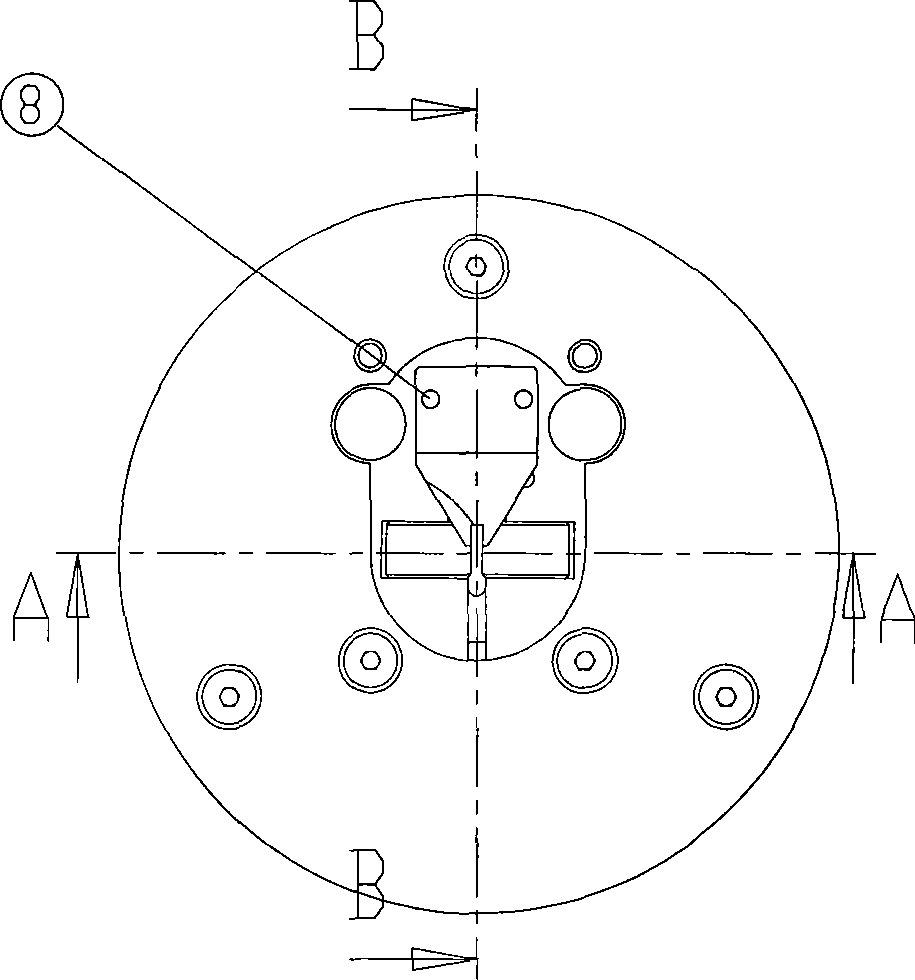

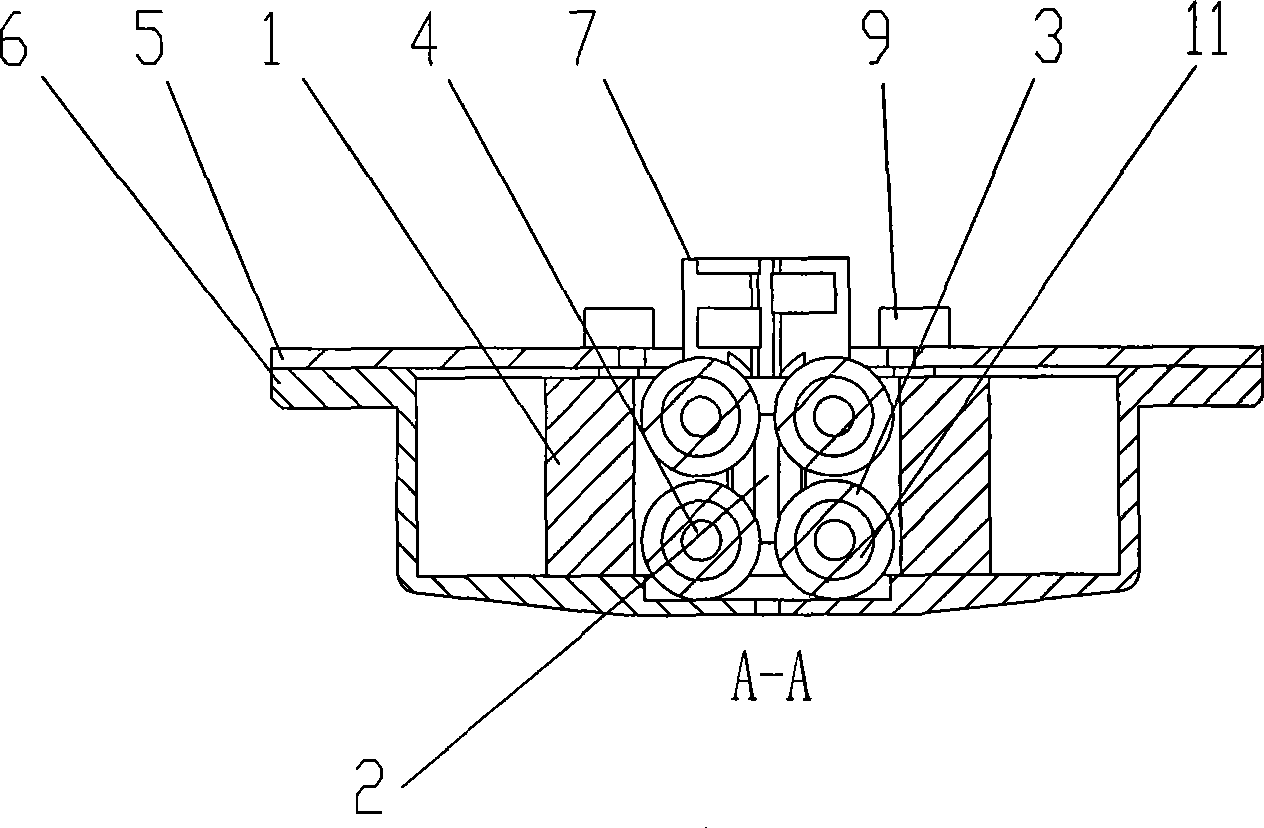

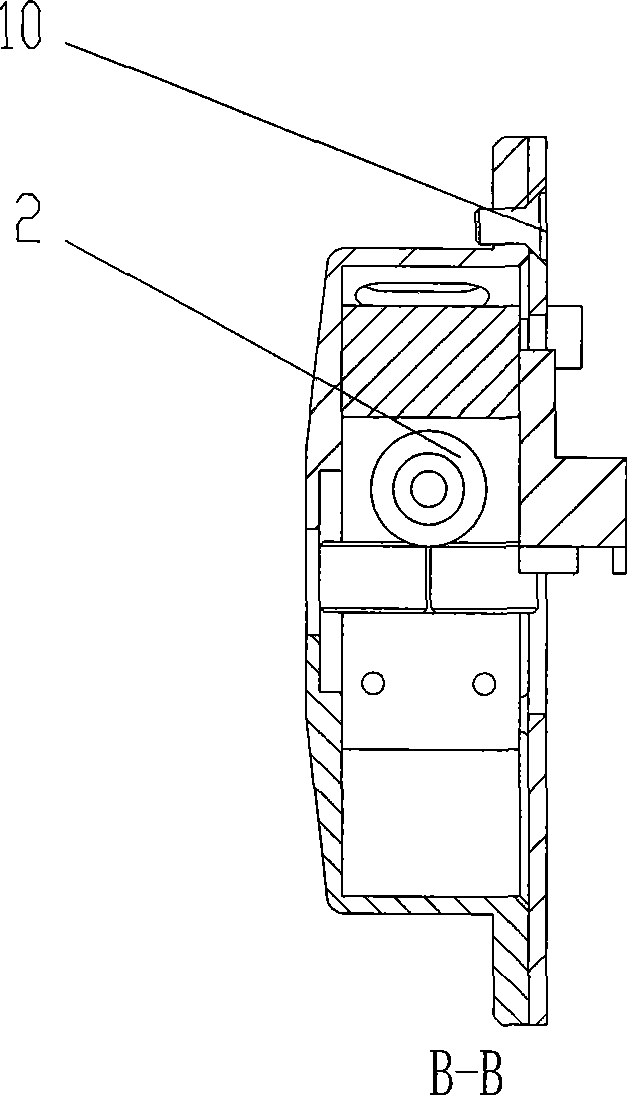

[0018] like Figure 1 to Figure 4 As shown, the present invention is used for the cutterhead device of automatic cutting machine, comprises cutterhead box 6, cutterhead cover 5, and flat grinding wheel 3, convex grinding wheel 2 and block 1 are installed in cutterhead box 6, flat grinding wheel 3 and The cam grinding wheel 2 is installed in the block 1 through the small shaft 4 , and the cam grinding wheel 2 is installed in the block 1 through the bearing 11 . Flat grinding wheel 3 is provided with four groups, and convex grinding wheel 2 is provided with one group, and four groups of flat grinding wheels 3 are arranged in two rows up and down, and every row is arranged side by side in two groups, and convex grinding wheel is located at the position between four groups of flat grinding wheels. Four sets of flat grinding wheels are combined with one set of convex grinding wheels and installed in the sipe block. It can keep the cutting knife in a state of dynamic balance for up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com