Hot wind pre-drying apparatus of continuous pigment dyeing pad dyer

A paint dyeing and pad dyeing machine technology, which is applied in the processing, drying, drying machine, etc. of textile materials, can solve the problems of unable to form air circulation, no exhaust mechanism, stains on dyed fabrics, etc., and achieve shortening of pre-drying time, save energy, and improve the effect of operating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

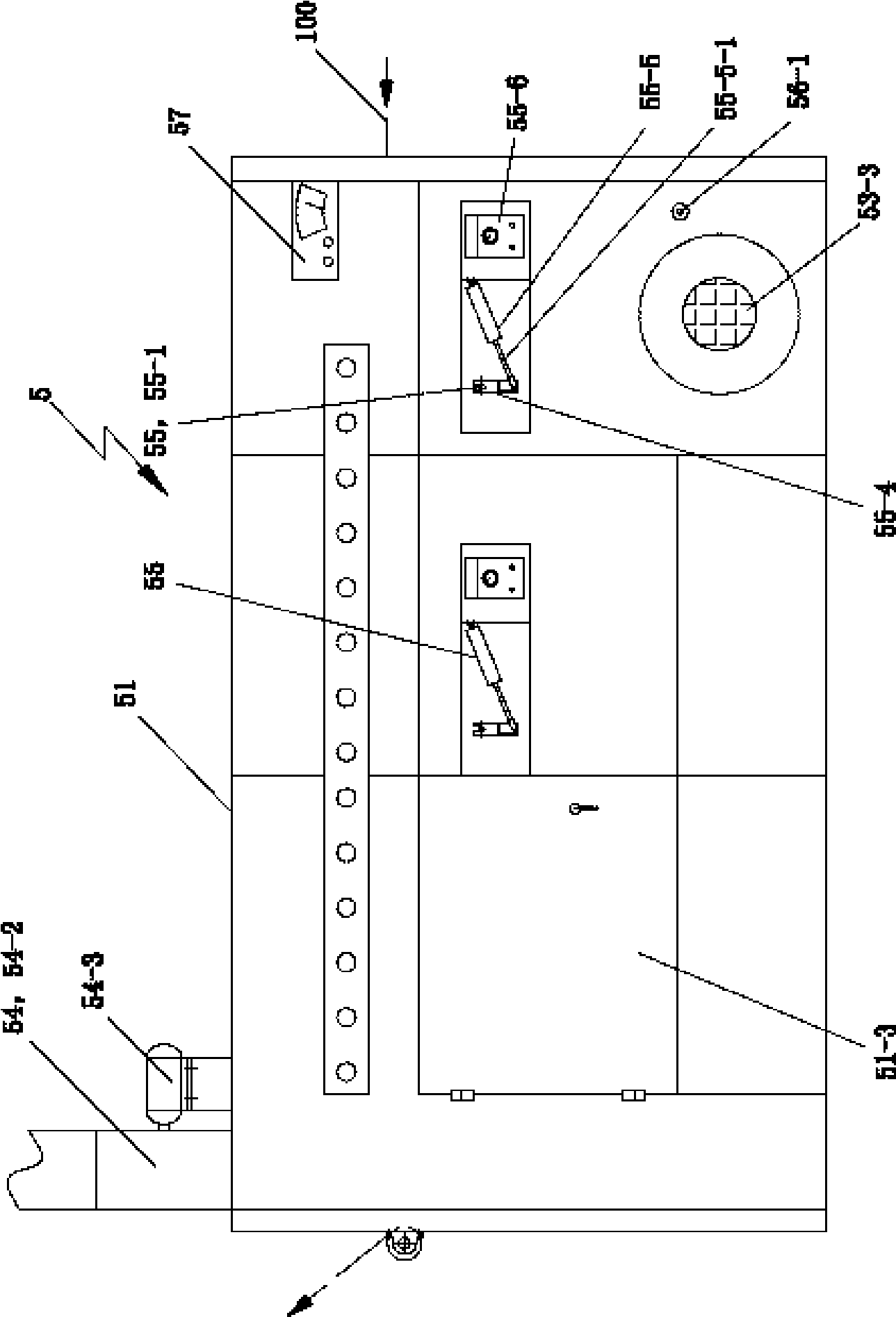

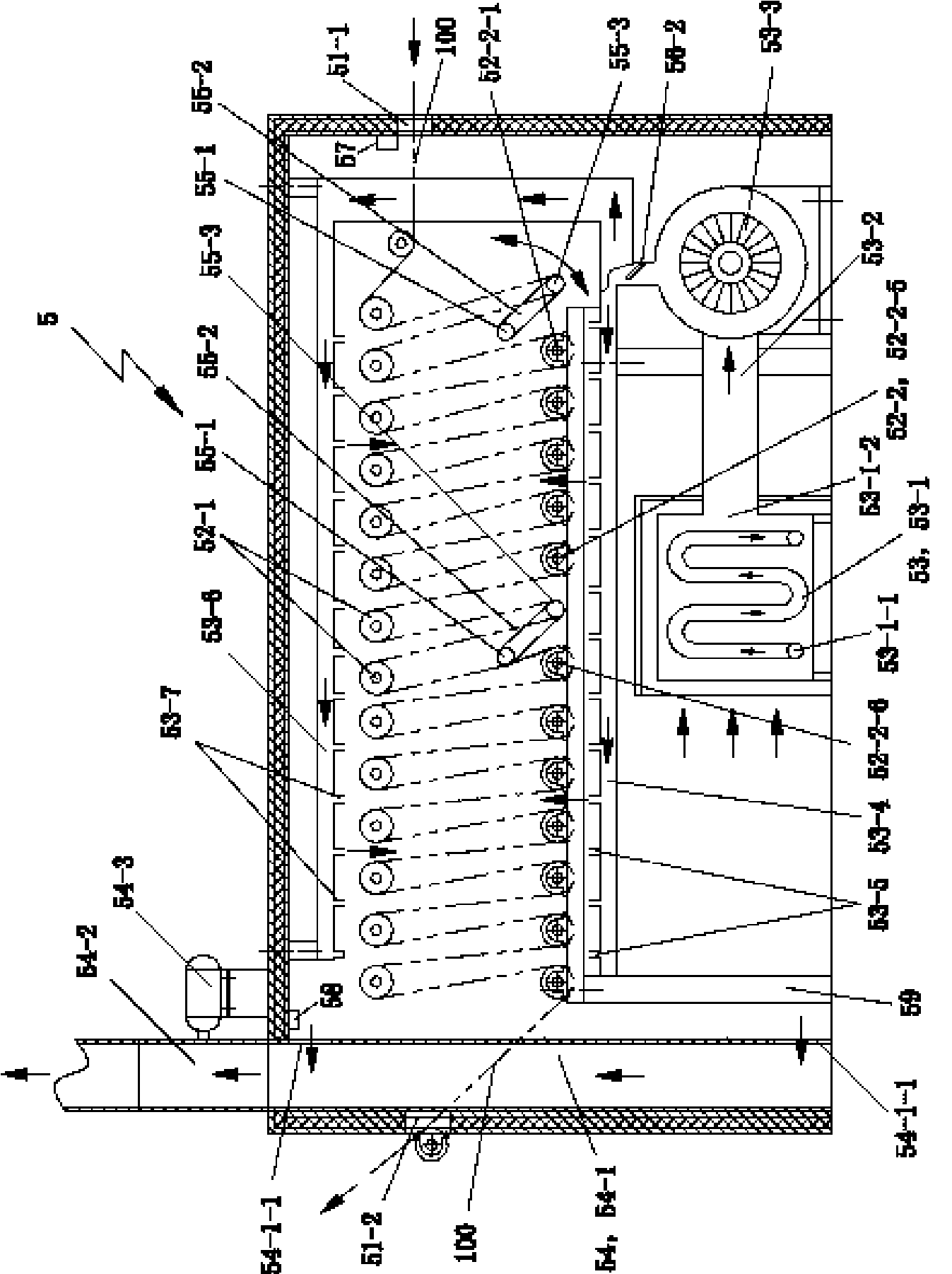

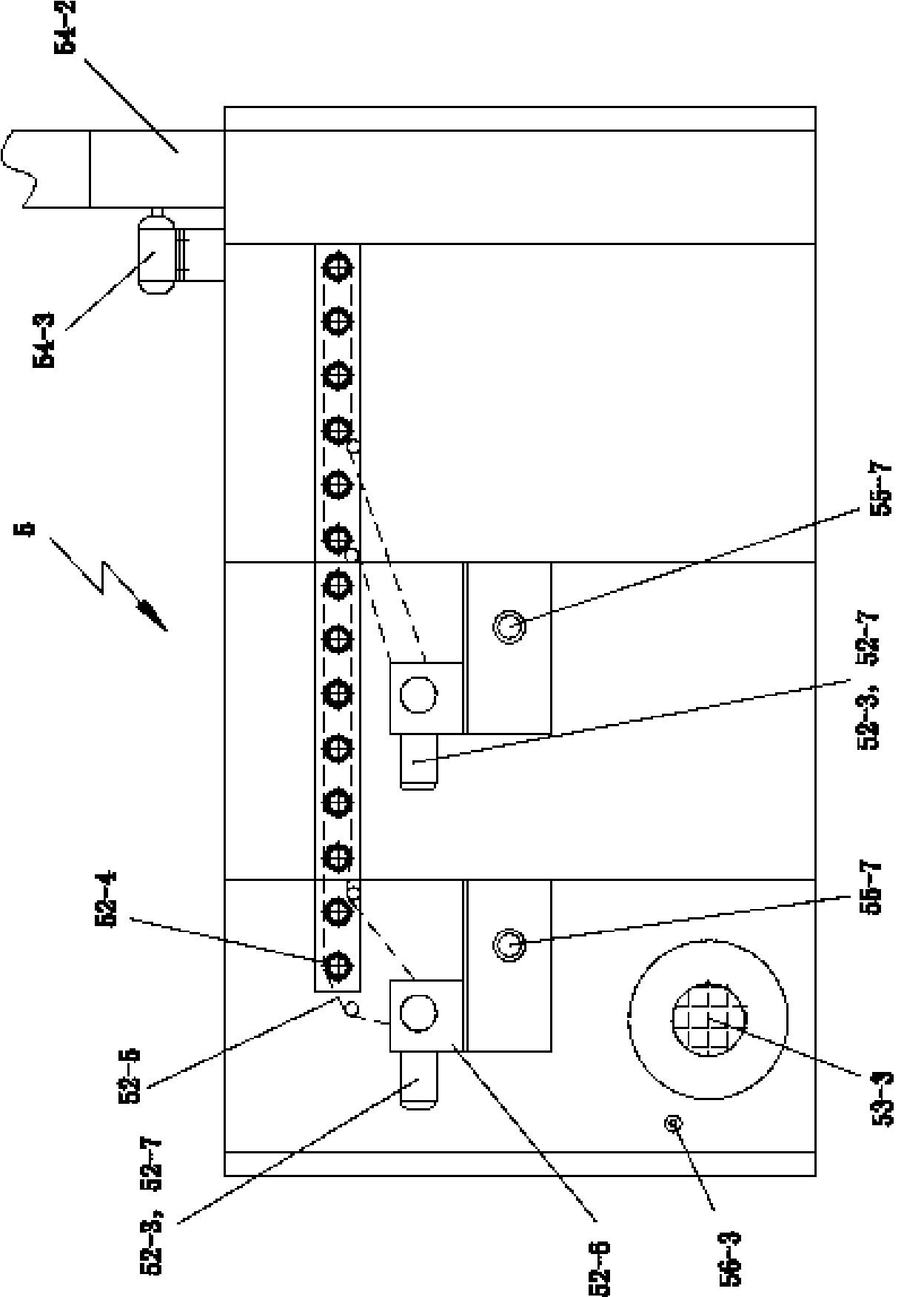

[0036] See figure 1 and figure 2 The hot air pre-drying device of the continuous paint dyeing pad dyeing machine of the present embodiment includes a box body 51, a fabric conveying device 52, a hot air system 53, an exhaust system 54, two tension adjustment mechanisms 55, two air volume adjustment mechanisms 56, Temperature detection device 57, humidity sensor 58, drying room frame 59, electric control box and the pneumatic diaphragm valve that is attached with feedback signal device.

[0037] A part of the fabric conveying device 52, the exhaust system 54, two air volume adjustment mechanisms 56 and the temperature detection device 57 is arranged in the box body 51, and the rest is arranged on the box body 51; the hot air system 53, the humidity sensor 58 and the drying room machine The frame 59 is arranged in the box body 51; the electric control box and the pneumatic diaphragm valve are arranged outside the box body 51.

[0038] still see figure 1 and figure 2 A clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com