Biohydrogen production by an artificial enzymatic pathway

A hydrogen production, enzymatic technology, applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of limited, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

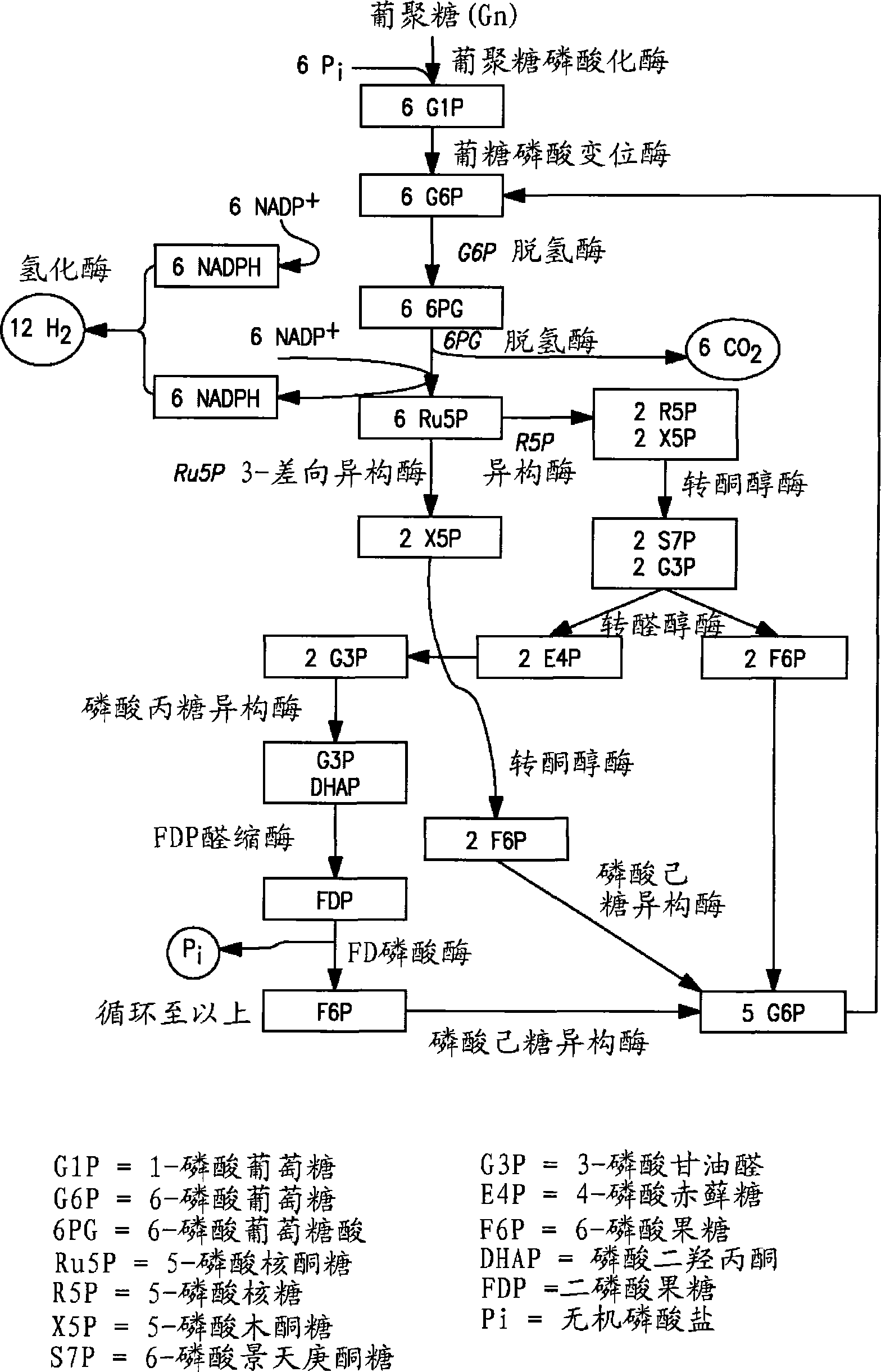

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

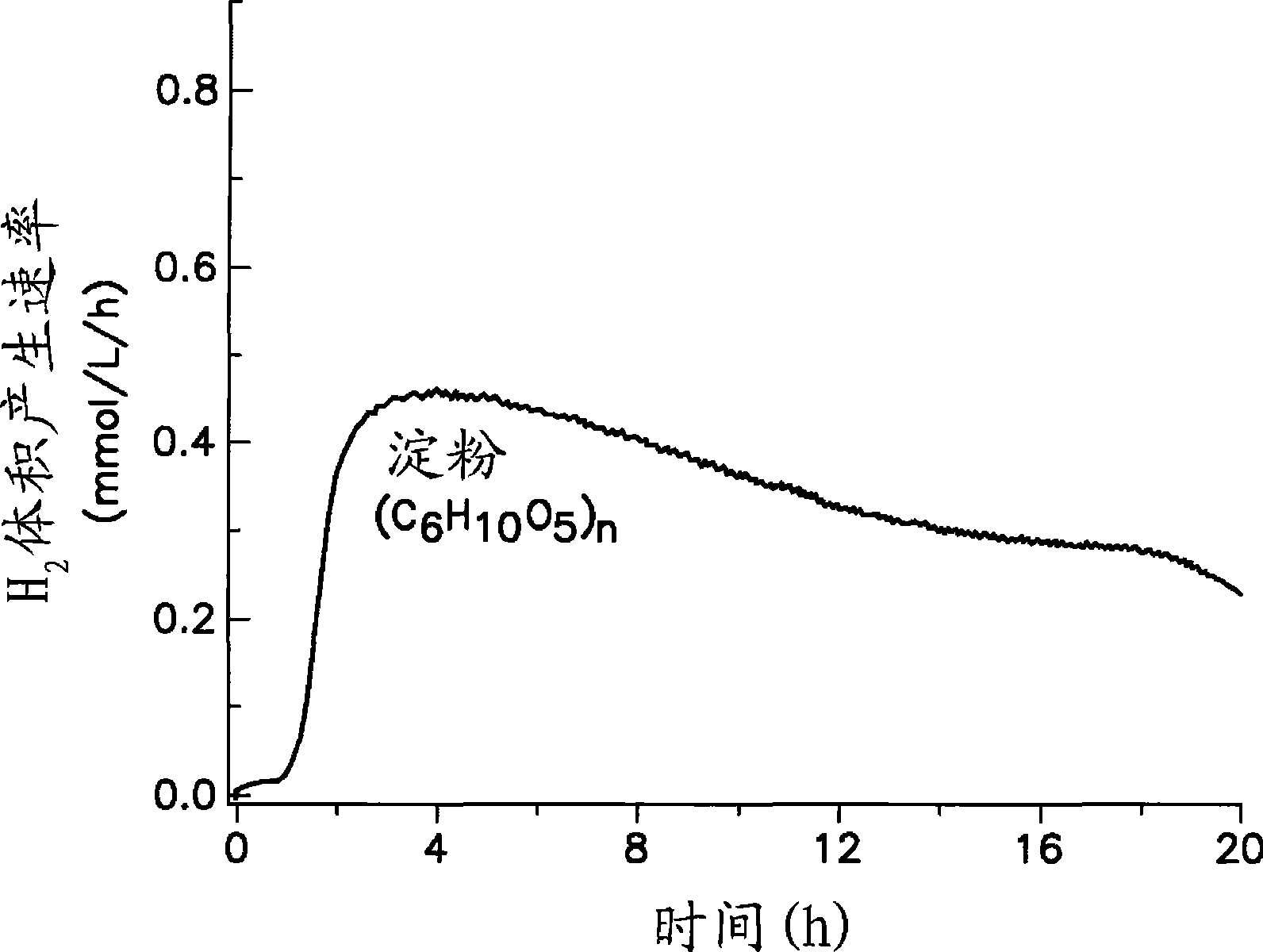

[0094] Example 1: Enzymatic production of H from starch and water 2 and CO 2

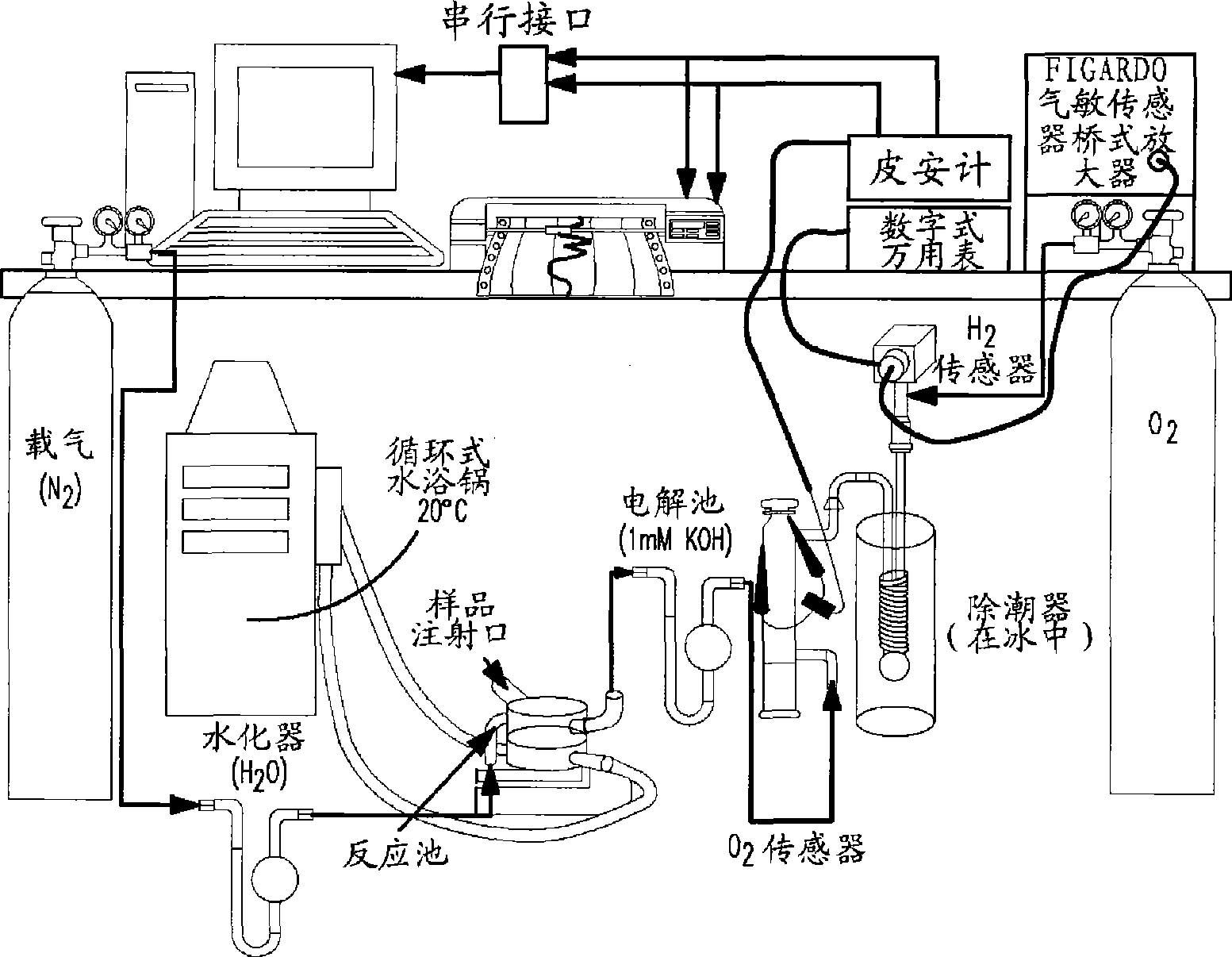

[0095] To illustrate the practical nature of the present methods, systems and compositions, starch was converted to hydrogen and carbon dioxide in a process according to the present invention. Experiments were performed in a continuous flow system equipped with an ice-cooled moisture eliminator. All chemicals and enzymes were purchased from Sigma-Aldrich Co. (U.S.A.) unless otherwise stated. In Table 1 all enzymes and their catalyzed reactions are listed. The working volume of a typical reactor is 2 mL. The system was continuously purged with helium at a flow rate of 50 mL / min. The temperature of the jacketed reactor was maintained at 30°C using a Polyscience (Niles, IL) circulating water bath.

[0096] Table 1: Enzymes and Catalyzed Reactions

[0097] EC Enzyme name reaction source unit 2.4.1.1

glycogen phosphorylase

(C 6 h 10 o 5 )n+Pi+H 2 O →

(C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com