Processing method for water-proof polyurethane imitation leather

A processing method, polyurethane technology, applied in chemical instruments and methods, textile and papermaking, synthetic resin layered products, etc. The effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1) Preparation of slurry: Mix 100 parts of polyester polyurethane UM-80F, 15 parts of dimethylformamide DMF, 7 parts of MEK, and 4 parts of leveling agent 224, then add modified polysiloxane defoamer 3 parts of BYK-A5551, use a 32KW high-speed mixer to stir at high speed for 1-2 hours, and when the viscosity of the slurry reaches 8000Pa.s or more, filter it twice with a 120-mesh nylon filter. The filtered slurry should be stored in a sealed plastic bag set In the iron drum, the standing time is more than 12 hours and it is used as fabric slurry.

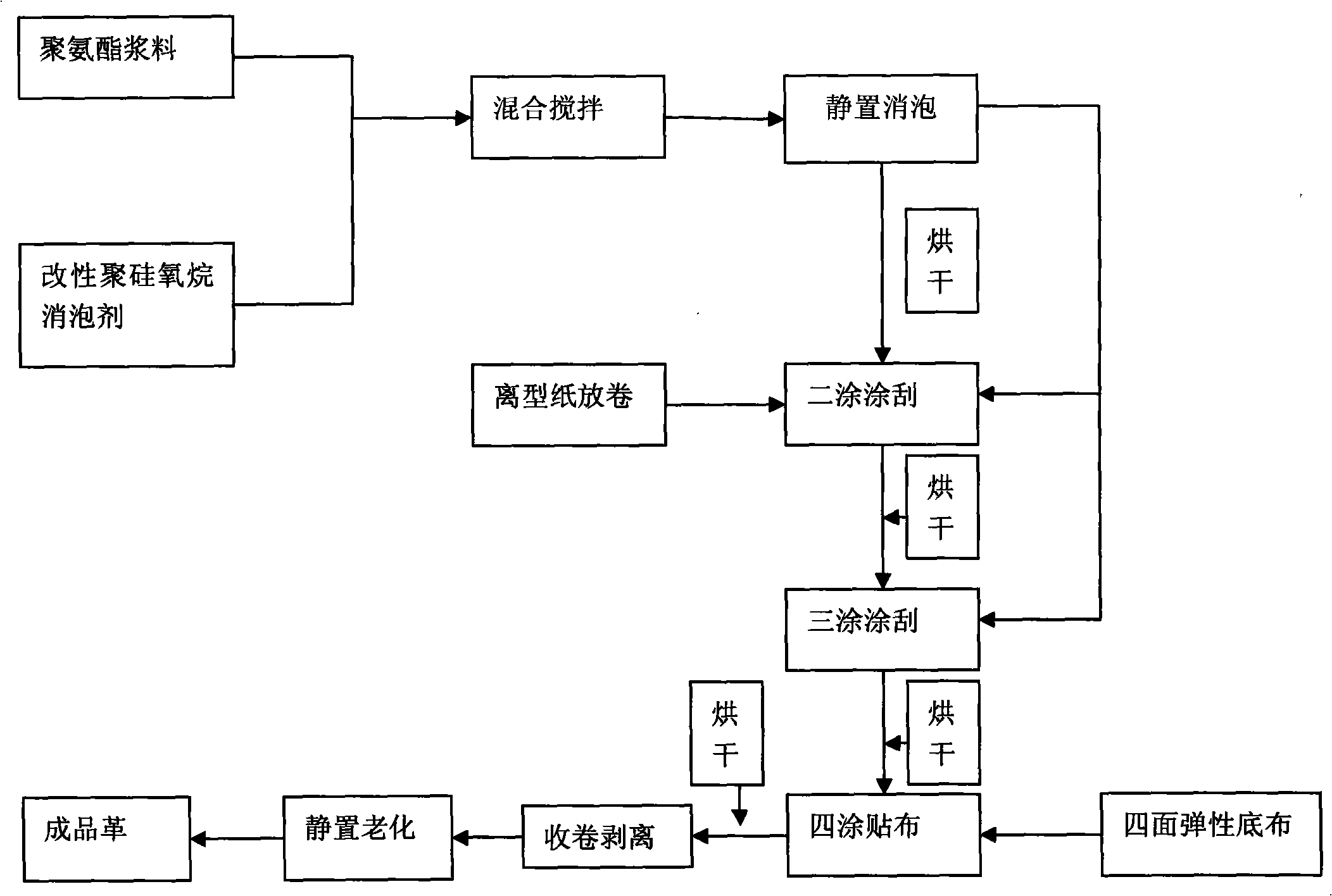

[0014] 2) Coating process: first, unwind the inspected release paper without holes into the No. 1 oven, preheat it at 60°C, and then reach the No. 1 coating station. 150g / m 2 After coating and scraping, enter the No. 2 oven and dry at 160°C to reach the No. 2 coating station. The same prepared slurry is used at 180g / m 2 After coating and scraping, enter the No. 3 oven, dry at 160-165°C, and then send it to the No. 3 coating ...

Embodiment 2

[0017] 1) Preparation of slurry: Mix 100 parts of polyester polyurethane UM-80F, 10 parts of dimethylformamide DMF, 5 parts of butanone MEK, and 2242 parts of leveling agent, then add modified polysiloxane defoamer BYK - A55512 parts, use a 32KW high-speed mixer to stir at high speed for 1-2 hours, and when the viscosity of the slurry reaches 8000Pa.s or more, filter it twice with a 120-mesh nylon filter. The filtered slurry should be stored in an iron drum with a sealed plastic bag Inside, the standing time is more than 12 hours and it is used as fabric slurry.

[0018] 2) coating process: with embodiment 1.

[0019] Product performance: According to this example, the water pressure resistance of the finished leather can reach about 6800mm

Embodiment 3

[0021] 1) Preparation of slurry: Mix 100 parts of polyester polyurethane UM-80F, 20 parts of dimethylformamide DMF, 10 parts of MEK, and 5 parts of leveling agent 224, then add modified polysiloxane defoamer BYK -5 parts of A5551, use 32KW high-speed mixer to stir at high speed for 1-2 hours, and filter twice with 120-mesh nylon filter when the viscosity of the slurry reaches more than 8000Pa.s. The filtered slurry should be stored in a sealed plastic bag suit In the bucket, the standing time is more than 12 hours and it is used as fabric slurry.

[0022] 2) coating process: with embodiment 1.

[0023] Product performance: According to this example, the water pressure resistance of the finished leather can reach about 5500mm

[0024] The source of the used main raw material of embodiment:

[0025] Polyester polyurethane UM-80F Zhangjiagang Dongfang Synthetic Resin Co., Ltd.

[0026] Modified polysiloxane defoamer BYK-A5551 Hangzhou Wuyou Plastic Chemical Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com