Mold cutter with improved mould-cutting knife structure suitable for reel material

A die-cutting machine and coil technology, which is applied in metal processing and other directions, can solve the problems of long production cycle, high cost of die-cutting tools, and cumbersome machines, so as to reduce production costs, reduce production costs and production requirements, and shorten production. The effect of the production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

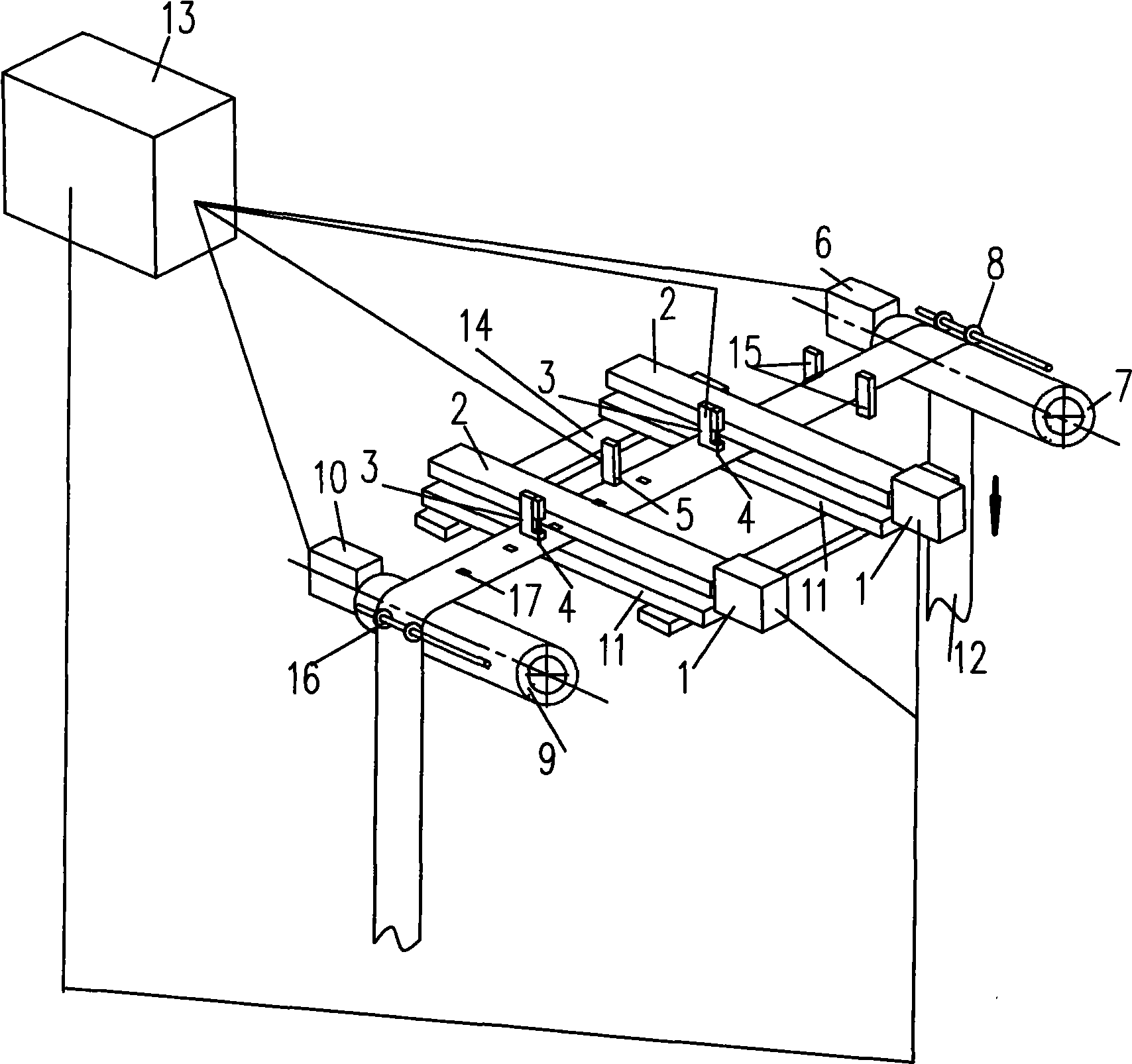

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The main parts and details of a die-cutting machine suitable for drum materials with improved die-cutting tool structure in the present invention:

[0019] 1. Knife feeding motor (servo or stepping motor), 2. Horizontal mechanism, 3. Tool holder, 4. Die cutting tool, 5. Mark detection sensor, 6. Traction motor (servo or stepping motor), 7. Traction Roller, 8. Traction roller, 9. Return roller, 10. Return motor, 11. Backing plate, 12. Roll material (die-cut paper), 13. Control system, 14. Knife holder guide rail, 15. Gear Block, 16. Go back and roll, 17. Mark.

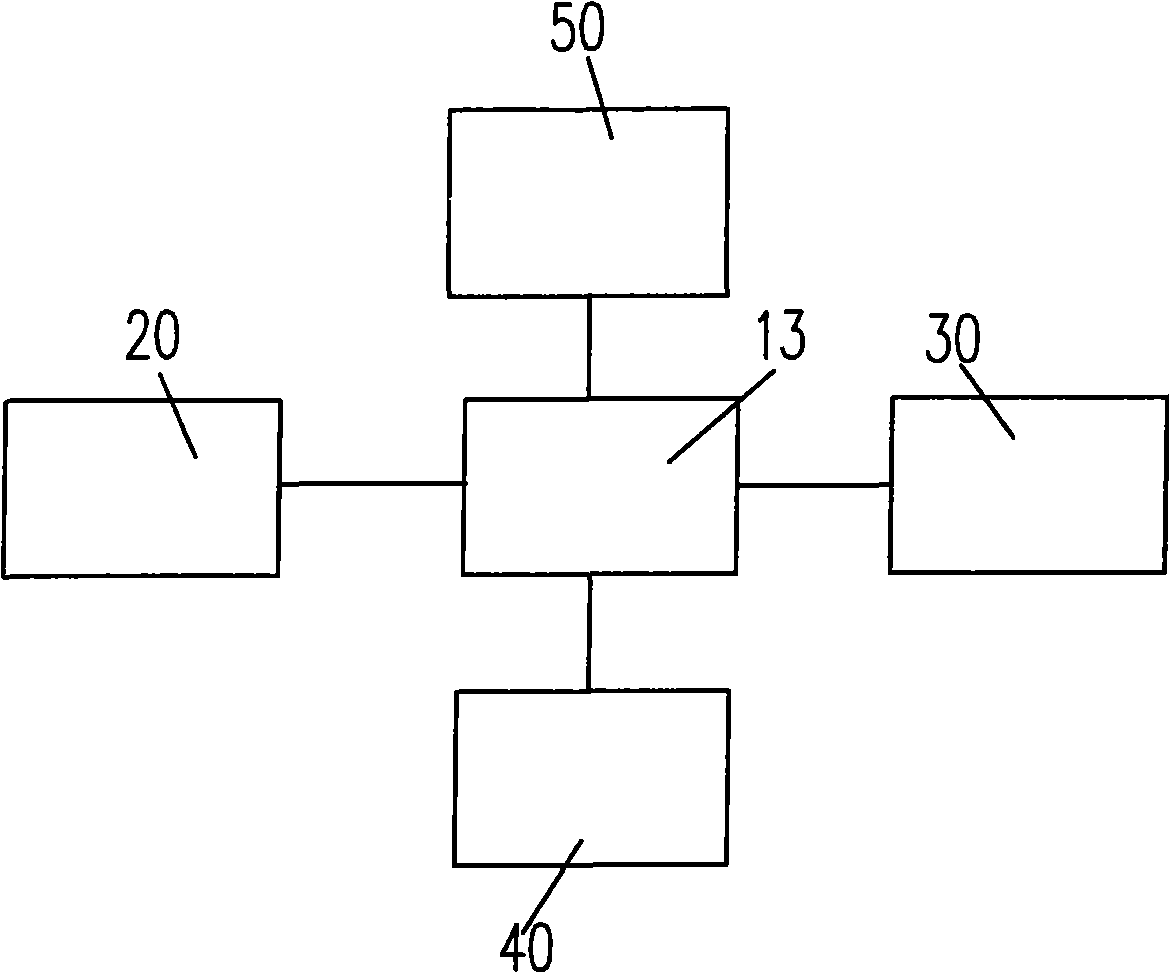

[0020] Such as figure 1 As shown, a die-cutting machine suitable for reel materials with an improved die-cutting tool structure of the present invention mainly includes a control system 13, a frame (not shown in the figure), a coil pulling unit 20, and a coil tensioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com