Method for preparing ammonium magnesium sulfate hexahydrate from giobertite

A magnesium ammonium sulfate and magnesite technology, applied in the direction of magnesium sulfate, ammonium sulfate, sulfate preparations, etc., can solve the problems of high production cost, complicated cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

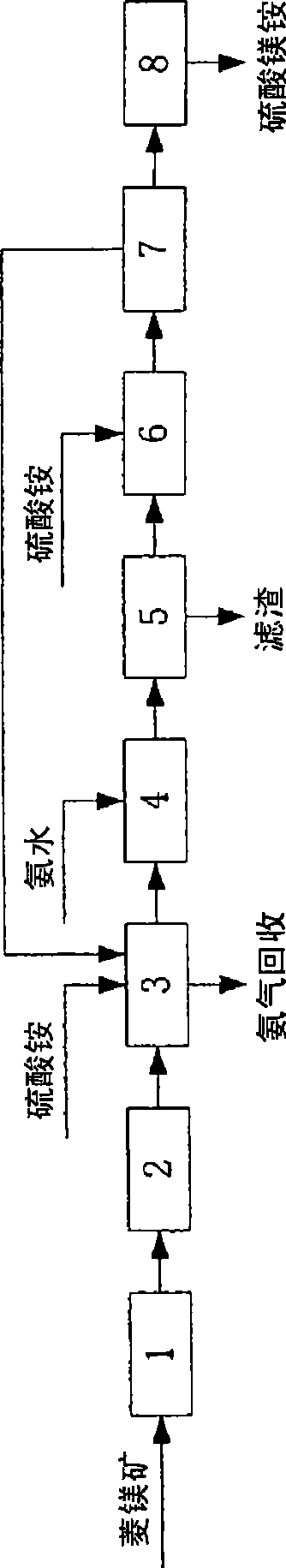

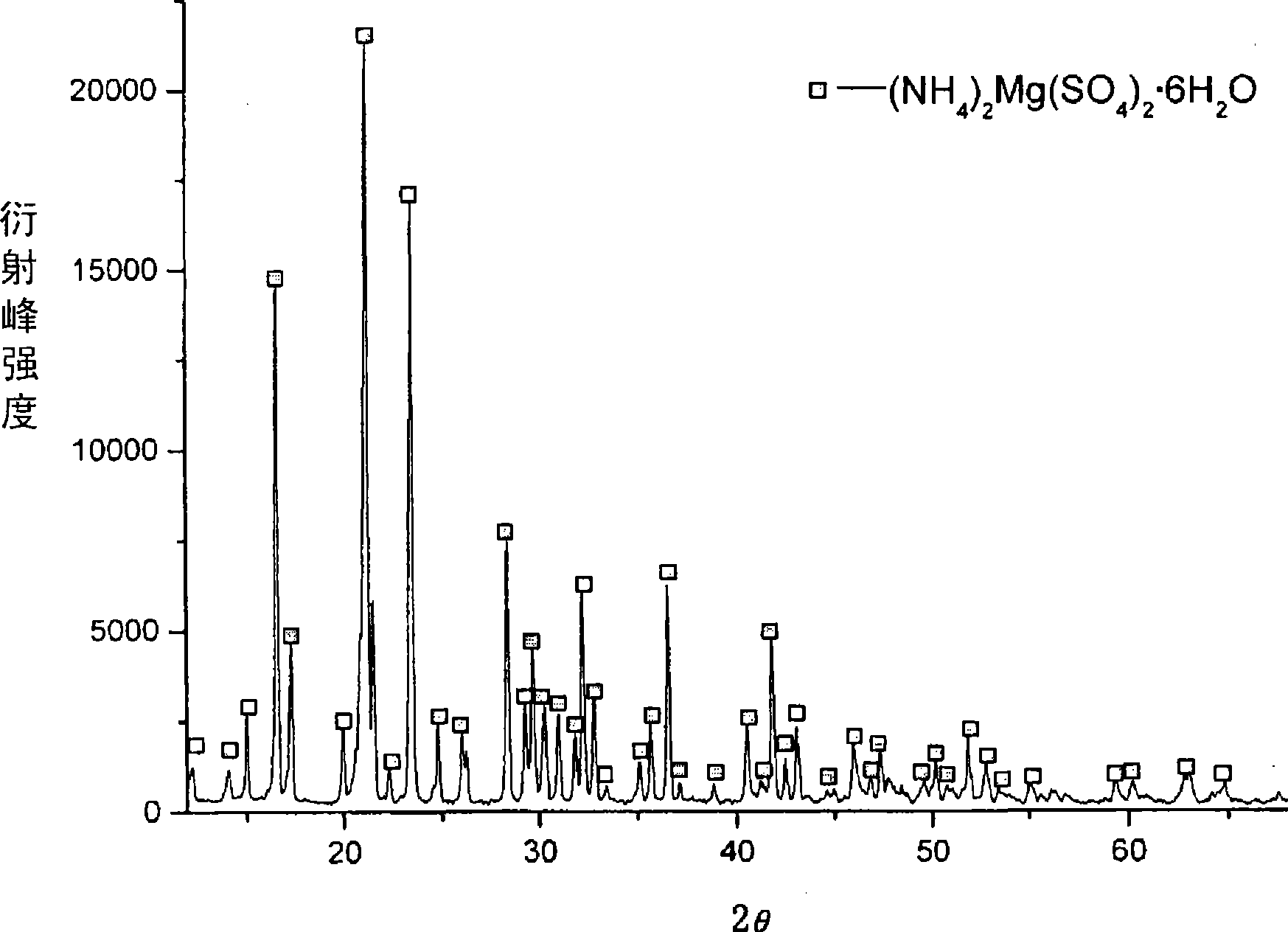

[0045] see figure 1 , put the magnesite into the roasting furnace 1, roast at 750°C for 2 hours, place it in the pulverizer 2 for fine grinding and pass through a 100-mesh sieve for later use. Add 1L of water into the 2L reaction kettle 3 with condensation and reflux, heat it to 100°C, add 220g of roasted magnesite powder into the reaction kettle, stir well, then gradually add 730g of ammonium sulfate and stir for 60min; Absorb with water. Lower the temperature of the slurry in the reaction kettle to 70° C., adjust its pH value to 8.2 with ammonia water in the sedimentation tank 4, stir for 30 minutes, and filter through the first filter 5 to obtain a filtrate. Transfer the filtrate to the crystallizer 6, add 1200 g of 50% ammonium sulfate solution and stir thoroughly, at 60°C, crystallize for 60 minutes and filter through the second filter 7, put the filter cake in the drier 8, and bake at 60°C Dry for 2 hours to obtain ammonium magnesium sulfate hexahydrate crystals (see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com