Separator for energy device and energy device having the same

A technology for equipment and energy, which is applied in the field of separators for energy equipment, can solve the problems of energy equipment without obtaining voltage retention rate, and achieve the effect of not being easy to internal short circuit, small aperture, and small unevenness of aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

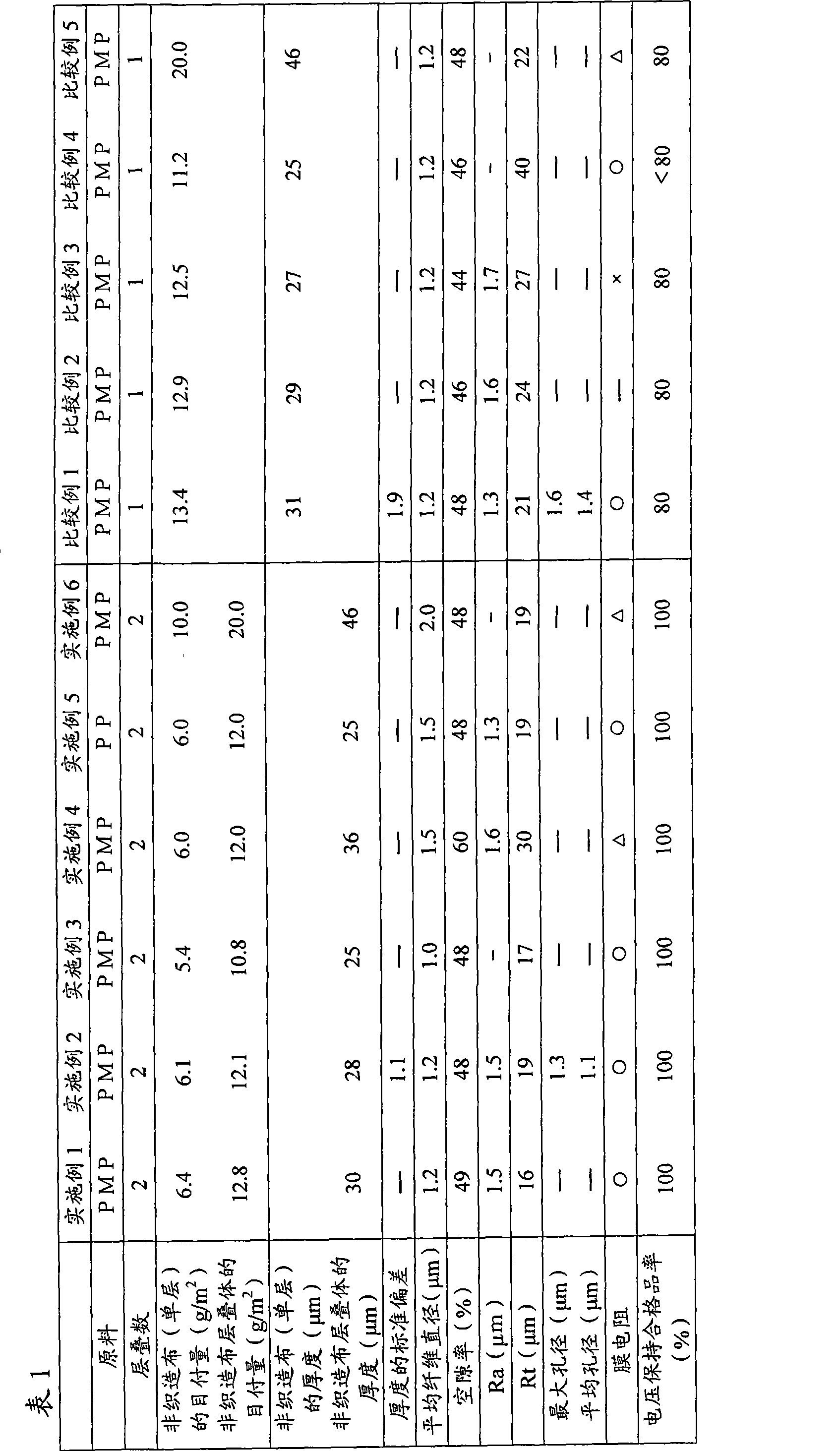

[0104] 4-Methyl-1-pentene copolymer (PMP, trade name: TPX DX820, manufactured by Mitsui Chemicals Co., Ltd., has a melting point of 240° C. and a melt flow rate of 180 g / 10 minutes at 260° C. under a load of 5 kg, The Vicat softening point is 178° C. (ASTM D1525)), melt-spun at a resin temperature of 350° C. by a melt-blowing method, and collected by a web forming machine to obtain a melt-blown nonwoven fabric. The average fiber diameter of the obtained melt-blown nonwoven fabric is 1.2 μm, and the weight per unit is 6.4 g / m 2 .

[0105] Two sheets of the above-mentioned melt-blown nonwoven fabric were prepared, stacked, and compacted with a calender roll (rubber roll and steel roll) set at 160° C. at a linear pressure of 10 kg / cm. The unit weight of the obtained nonwoven fabric laminate was 12.8 g / m 2 , with a thickness of 30 μm and a porosity of 49%. In addition, the Ra value was 1.5 μm, and the Rt value was 16 μm. The film resistance of the sample was good.

[0106] Ne...

Embodiment 2~4 and Embodiment 6

[0110] Using the same 4-methyl-1-pentene copolymer as in Example 1, a melt-blown nonwoven fabric was produced. As shown in Table 1, adjust the unit weight of the melt-blown nonwoven fabric to 5.4-10.0g / m 2 , the average fiber diameter of the melt-blown nonwoven fabric is adjusted to 1.0-2.0 μm.

[0111] Furthermore, using the same apparatus as in Example 1, the pressing force was adjusted, and two melt-blown nonwoven fabrics were laminated to obtain a separator for energy equipment. Table 1 shows the evaluation results of the obtained separators for energy equipment.

Embodiment 5

[0113] A propylene homopolymer (melt flow rate 20 g / 10 minutes, melting point 160° C.) was used instead of the 4-methyl-1-pentene copolymer to produce a melt-blown nonwoven fabric. The evaluation results of the obtained melt-blown nonwoven fabric are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com