Column gear-noncircular gear drive system transplanting mechanism capable of eliminating pitch play

A non-circular gear and backlash elimination technology, applied in the field of agricultural machinery, can solve problems such as affecting the uniformity of seedling taking amount and transplanting quality, unfavorable elimination of backlash, processing and assembly errors, etc. Large gear module, the effect of eliminating backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

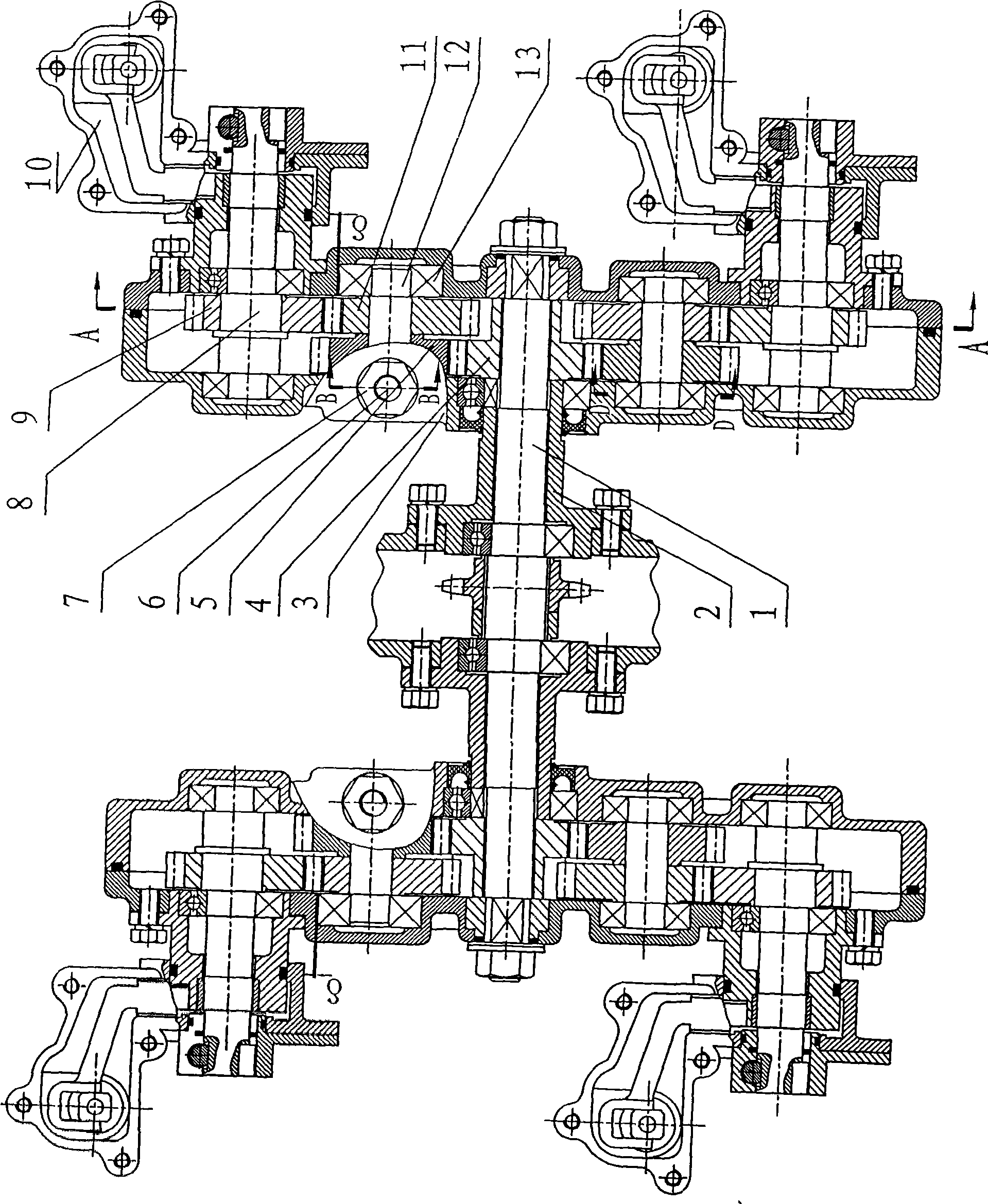

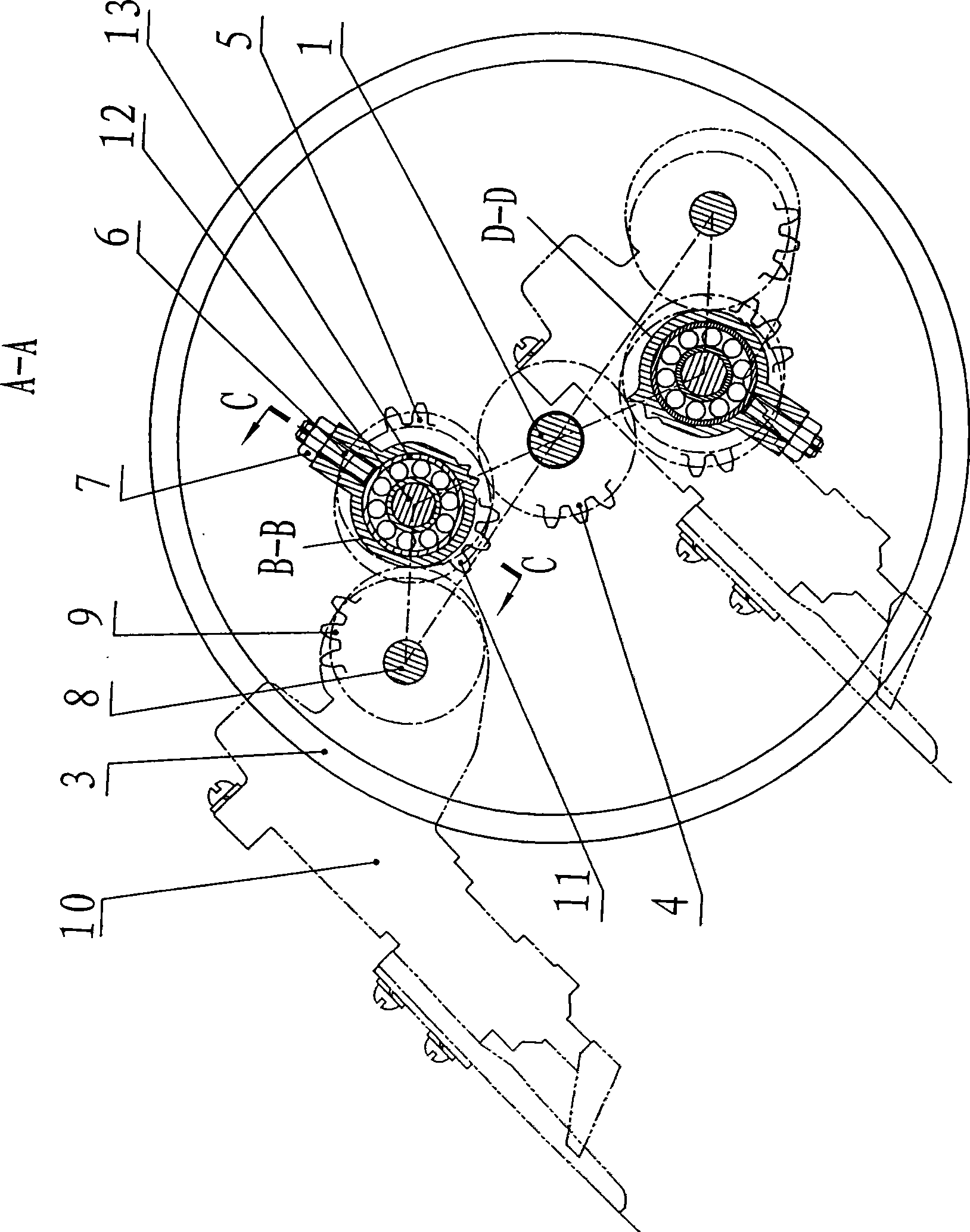

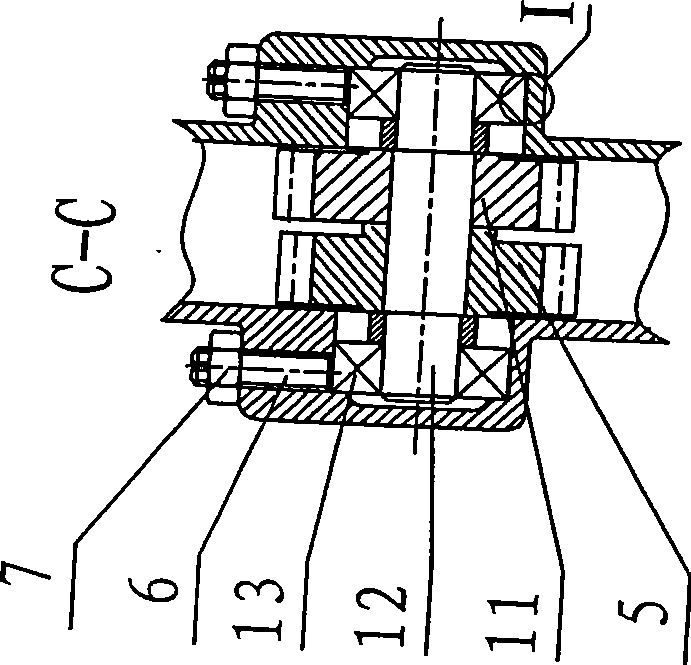

[0021] Such as figure 1 , figure 2 As shown, the present invention comprises the same left and right transmission boxes of the structure respectively installed at the two ends of the central axis 1, and the planting arms installed on the left and right transmission boxes. The structure in the right transmission case 3 is as follows: the right central cylindrical gear 4, which is vacantly sleeved on the right end of the central shaft 1, is fixedly connected with the frame through the tooth-embedded right flange 2, and is symmetrically arranged on both sides of the right central cylindrical gear 4. Install the upper and lower right intermediate cylindrical gears 5 and the upper and lower right intermediate non-circular gears 11 fixed on the upper and lower right intermediate shafts 12 and the upper and lower right planetary non-circular gears fixed on the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com