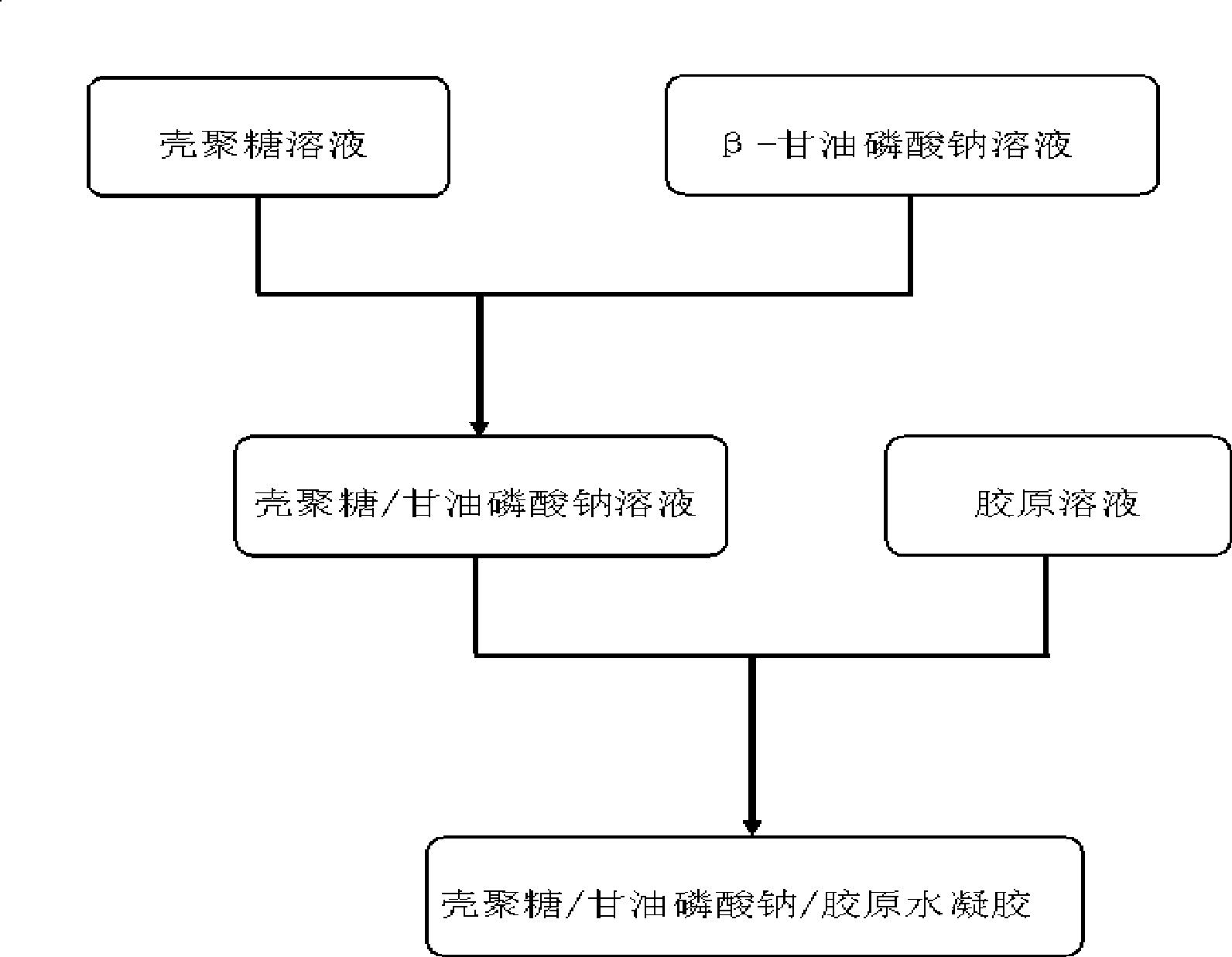

Method for preparing injectable chitosan/sodium glycerophosphate/collagen hydrogel

A technology of sodium glycerophosphate and collagen hydrogel, which is applied in medical science, prosthesis, etc., can solve the problems of low mechanical strength and fast degradation, and achieve the effects of simple method, good biocompatibility, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 220mg chitosan in 10mL0.1mol.L -1 Mix well in the acetic acid solution to make a 2.2% (W / V) solution, and store in an ice bath; dissolve 2g of β-glycerophosphate sodium powder in 2mL triple-distilled water to make a 50% (W / W) solution; store in an ice bath , add 2mL sodium glycerophosphate solution dropwise into 10mL chitosan solution, stir well to obtain chitosan / sodium glycerophosphate solution; add 7.5mL tri-distilled water to 5mL collagen and mix evenly, then add the mixed solution to 312.5 0.1molL of mL -1 Collagen solution was prepared in NaOH solution; an equal volume of chitosan / sodium glycerophosphate solution and collagen solution were mixed under ice bath, and stirred for 10 minutes to obtain chitosan / sodium glycerophosphate / collagen hydrogel.

Embodiment 2

[0025] Dissolve 200mg chitosan in 10mL 0.1molL -1 Mix well in hydrochloric acid solution to make a 2% (W / V) solution, and store in an ice bath; dissolve 1g of β-glycerophosphate sodium powder in 1.5mL triple-distilled water to make a 40% (W / W) solution; Under the bath, add 1.5mL sodium glycerophosphate solution dropwise into 10mL chitosan solution, and stir thoroughly to obtain chitosan / sodium glycerophosphate solution; add 3mL triple-distilled water to 2mL collagen and mix evenly, and then mix the solution Add 125mL of 0.1molL -1 In the NaOH solution, the collagen solution is obtained; the prepared chitosan / sodium glycerophosphate solution and the collagen solution are mixed in an ice bath at a volume ratio of 10:1, and stirred for 10 minutes to obtain a gel that can be transformed into a gel at body temperature. chitosan / sodium glycerophosphate / collagen hydrogel.

Embodiment 3

[0027] Dissolve 150mg chitosan in 10mL 0.1molL -1 Mix well in the acetic acid solution to make a 1.5% (W / V) solution, and store in an ice bath; dissolve 1.64g of β-sodium glycerophosphate powder in 2mL triple-distilled water to make a 45% (W / W) solution; store in an ice bath Next, add 1mL sodium glycerophosphate solution dropwise into 6mL chitosan solution, stir well to obtain chitosan / sodium glycerophosphate solution; add 15mL triple distilled water to 10mL collagen and mix evenly, then add the mixed solution to 625mL 0.1molL -1 In the NaOH solution, the collagen solution is prepared; the prepared chitosan / sodium glycerophosphate solution and the collagen solution are mixed in an ice bath at a volume ratio of 1:10, stirred for 10 minutes, and obtained can be transformed into a gel at body temperature. chitosan / sodium glycerophosphate / collagen hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com