Microwave detection method and apparatus for moisture contained in coal on mine conveyer belt

A microwave detection and conveyor belt technology is applied in the field of coal moisture detection, which can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

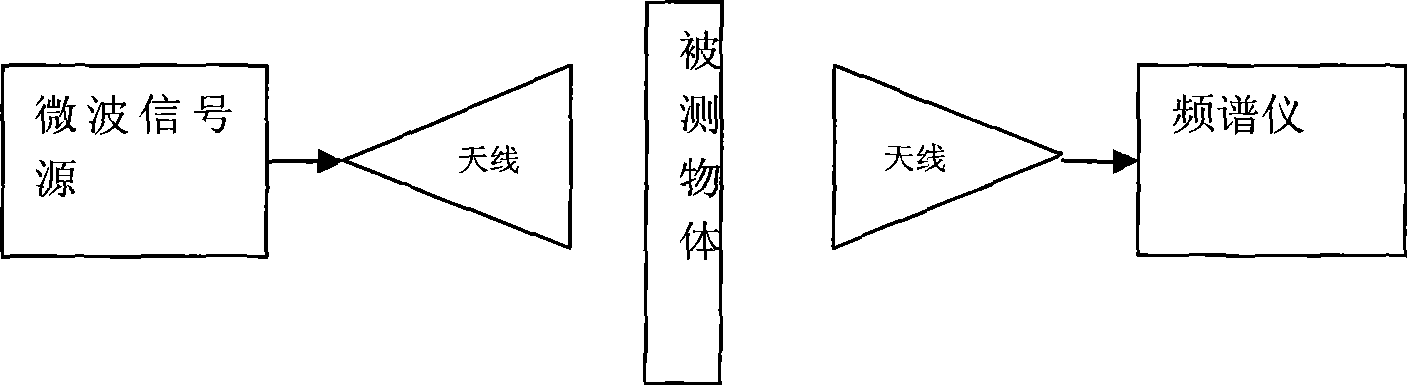

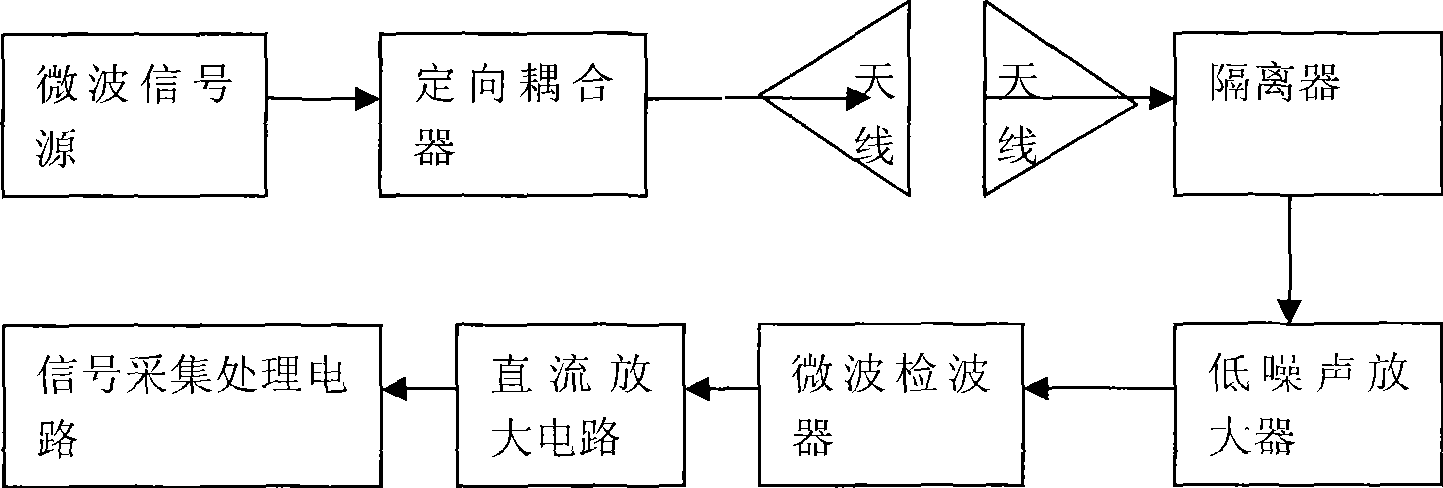

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail: the microwave detection method of coal moisture content on the mine conveyer belt, comprises the following steps: 1) determination of microwave frequency: under dry situation and after adding water by coal under different frequencies to microwave signal The attenuation test is to determine the maximum absorption frequency of microwave signals by water, so as to determine the microwave frequency to be selected. The microwave frequency is determined to be 9.7GHz through experiments. For specific test methods, see figure 1 ; 2) Determine the relationship between coal moisture content and microwave signal attenuation: first measure the microwave attenuation after passing through the conveyor belt under various samples, and then use the drying method to accurately measure the coal moisture content on the conveyor belt. This draws the relationship curve of microwave attenuatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com