Steam turbine designed to facilitate late modification for operation with power plant incorporating carbon capture facilities

A steam turbine, turbine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of carbon capture and sequestration technology not fully developed, reducing efficiency, not equipped with carbon capture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

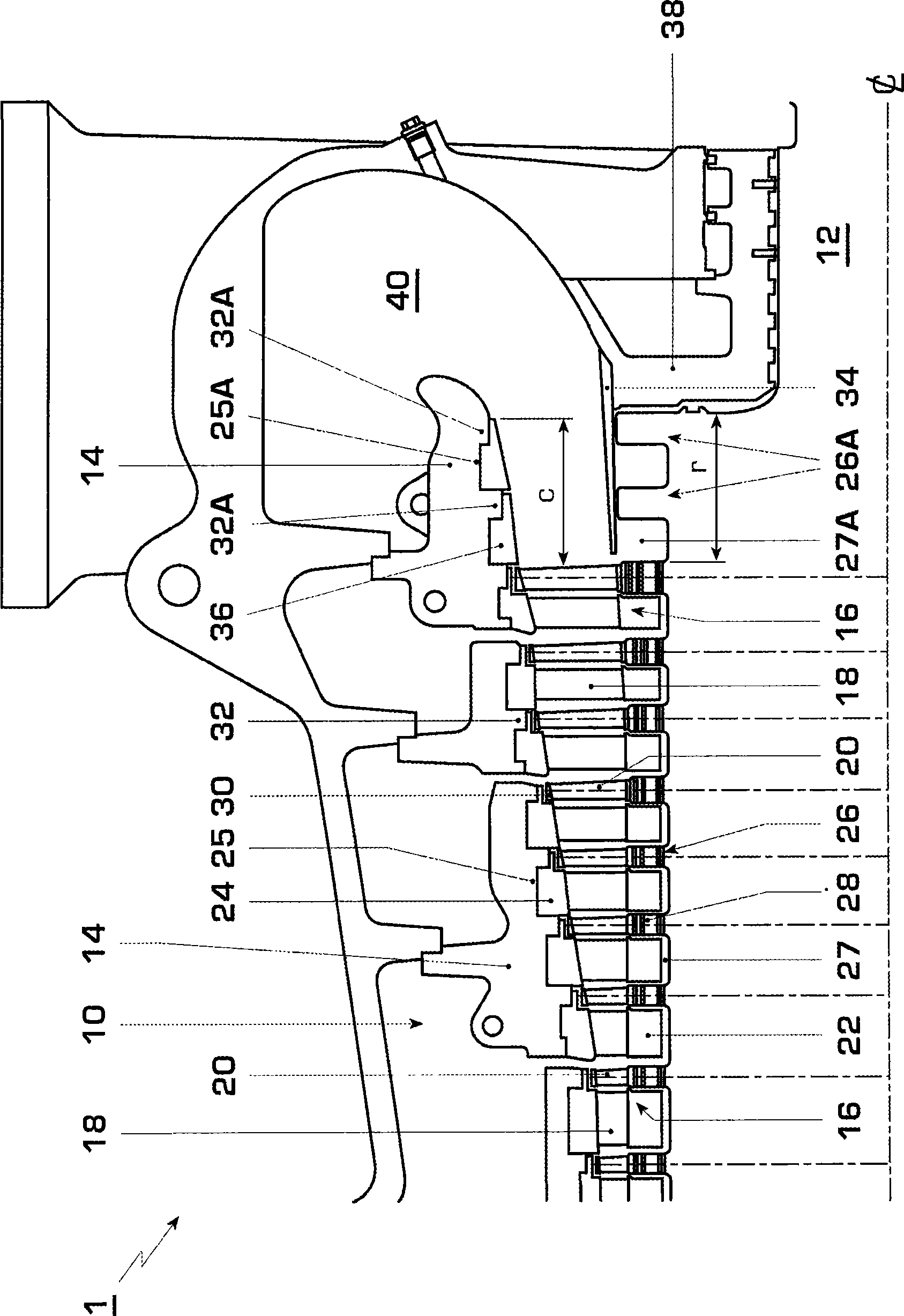

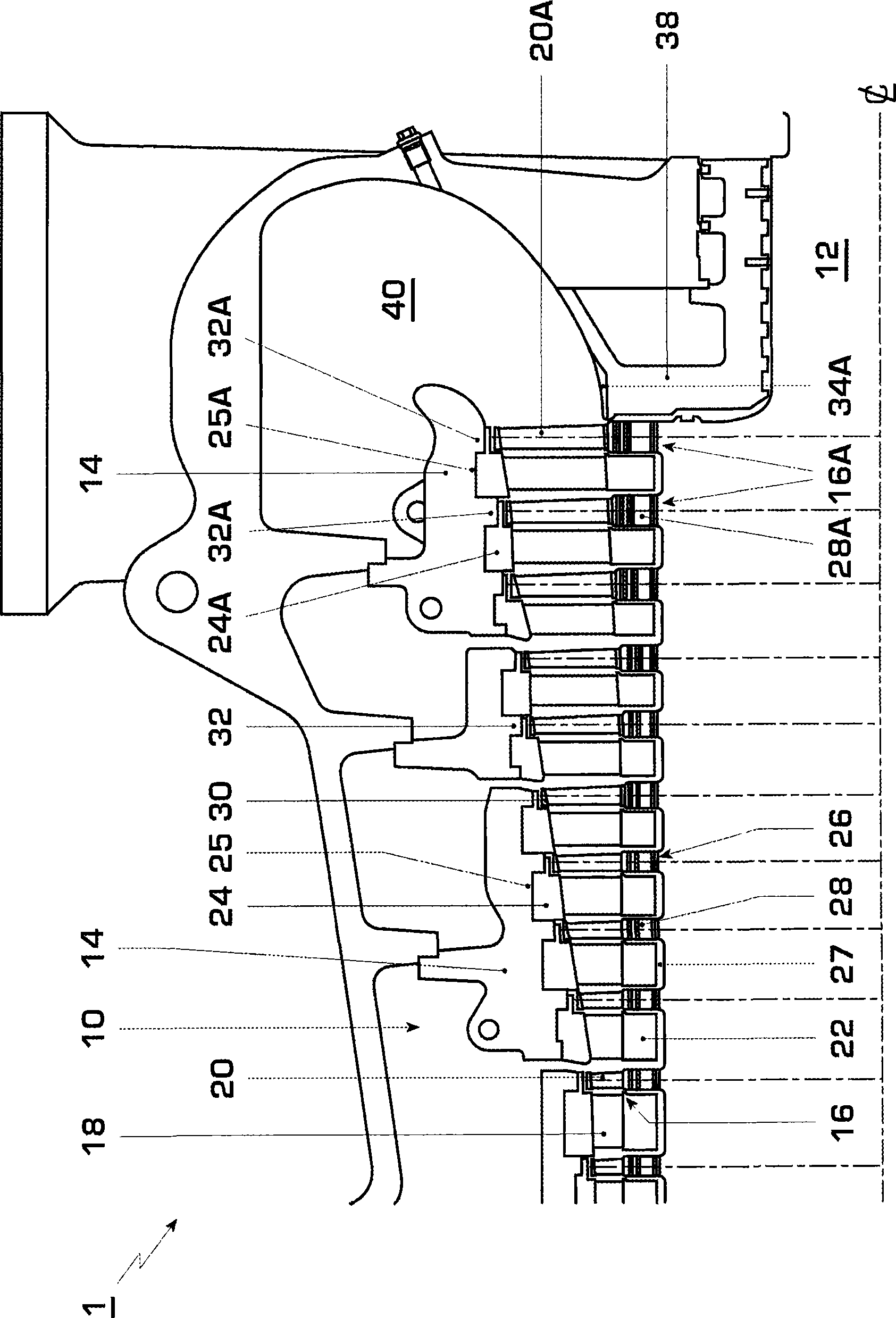

[0019] Briefly, a preferred embodiment of the invention includes a steam turbine for a fossil fuel power plant that facilitates carbon capture. The turbines include intermediate pressure (IP) turbines manufactured to operate at a specific expansion ratio and supply the low pressure turbine at a specific steam volumetric flow rate. The IP turbine is made with extra length in its rotor and casing to allow the subsequent addition of additional turbine stages to increase the turbine expansion ratio at its outlet and volume flow rate. After adding an additional stage, the resulting additional volume flow rate of process steam can be vented from the IP turbine outlet to feed the post combustion carbon capture process without affecting the ability of the IP turbine to supply the low pressure turbine with the original volume flow rate of steam.

[0020] now refer to figure 1 , an axial flow steam turbine 1 is part of a "facilitated carbon capture" fossil fuel power plant, where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com