Crawling type separator and realization method thereof

A realization method and separator technology, which are applied in the field of solid-liquid gas separation equipment and solid-liquid separation equipment, can solve the problems of secondary pollution of flushing water, heavy operation workload, difficult maintenance and other problems, and achieve low equipment loss and safe operation. Reliable, huge social and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, as an example, the corresponding slurry is drilling fluid, and the separation operation of solid-liquid-gas three-phase substances can be directly performed by using the peristaltic screen separator of the present invention.

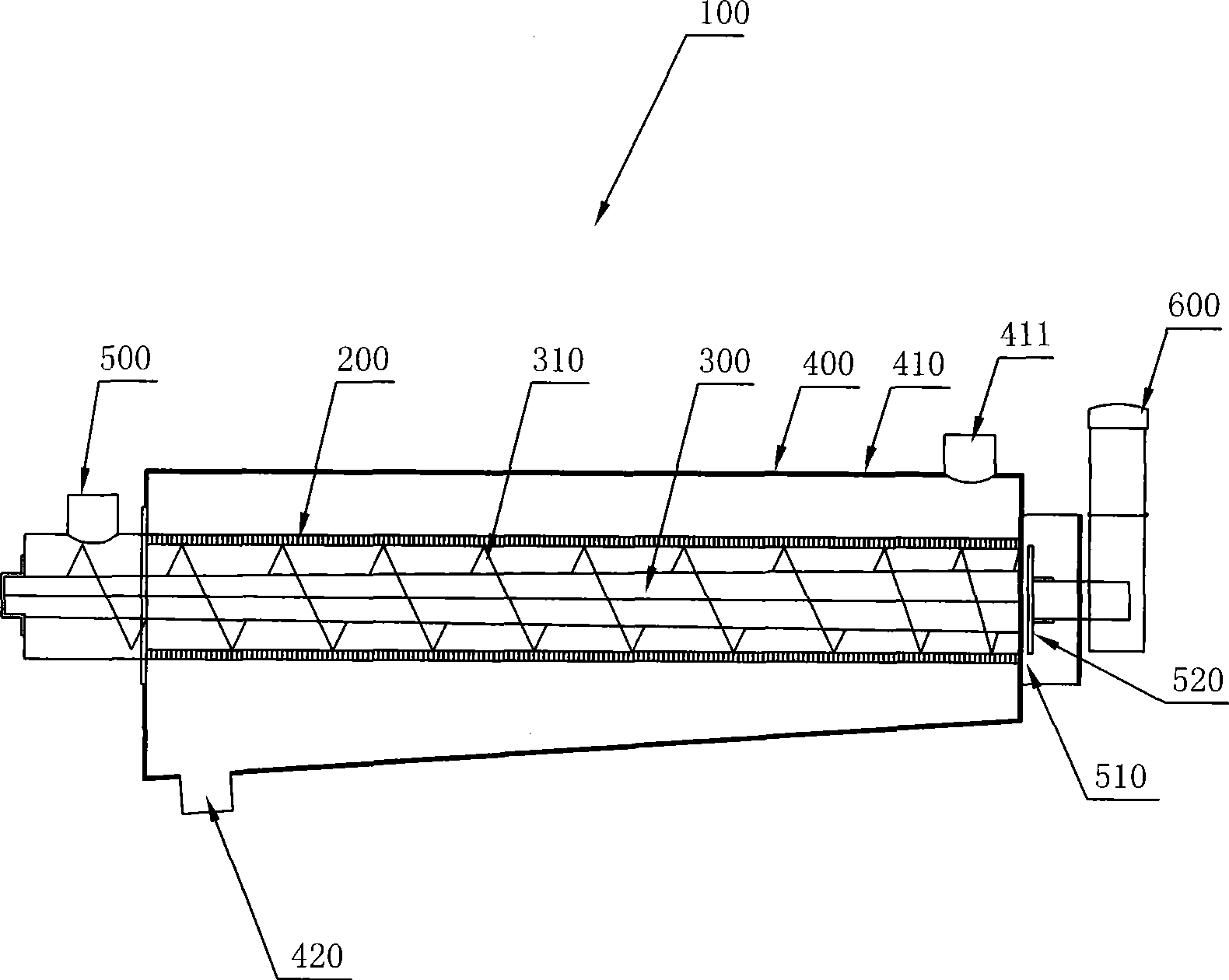

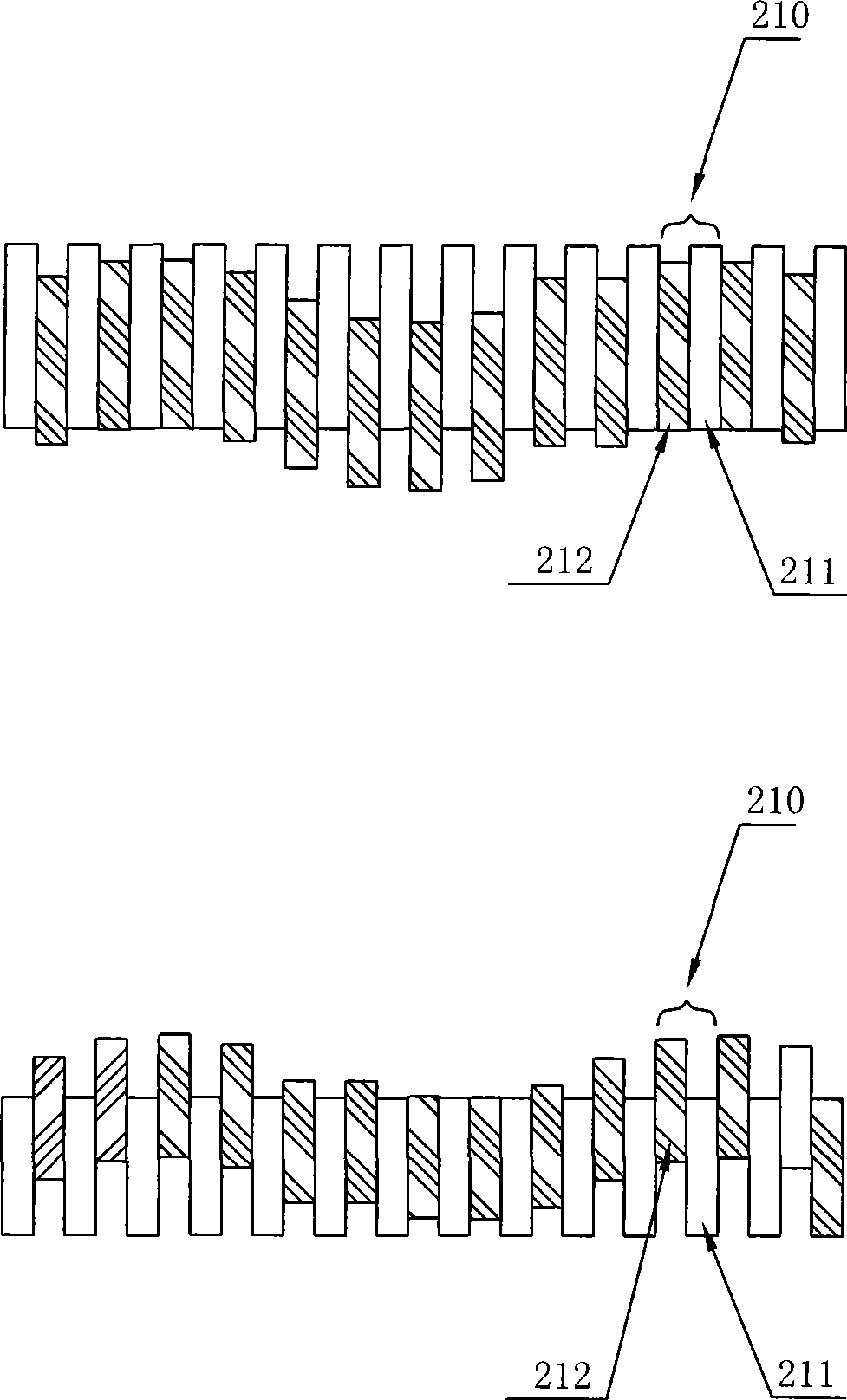

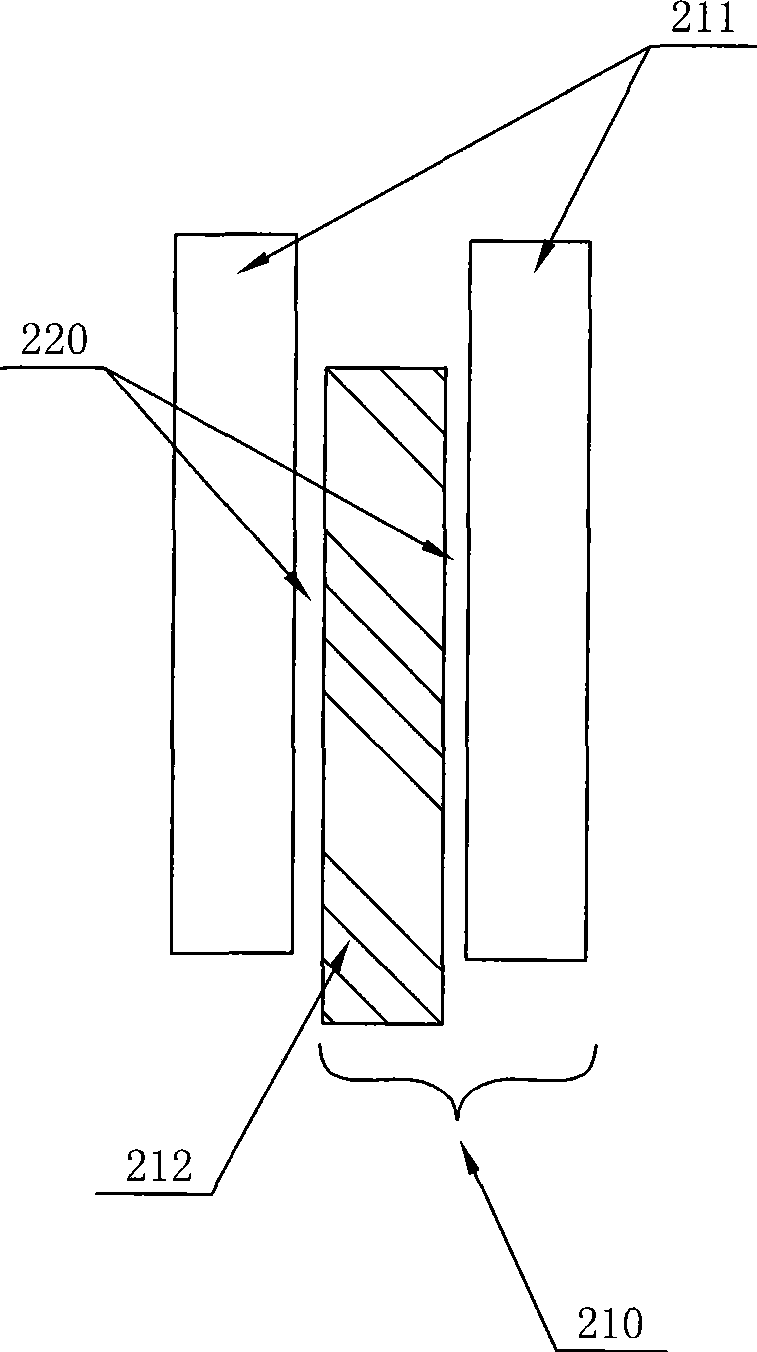

[0042] refer to figure 1 , figure 2 , image 3 and Figure 4 As shown, the main body of the equipment is composed of a peristaltic screen 200 in the middle, a screw shaft 300 in the center with the functions of transmission, conveying and extrusion, and a peristaltic screen tank 400 on the outside.

[0043]In this embodiment, the peristaltic sieve tank body 400 is a vacuum tank 410 . The vacuum tank 410 is used to achieve the purpose of vacuuming. As an example and not a limitation, it can adopt an eccentric conical structure with a vacuum induction pipe 411 on the top and a liquid discharge pipe 420 on the bottom.

[0044] The peristaltic screen 200 is composed of a plurality of peristaltic units 210 , and each peristaltic unit...

Embodiment 2

[0057] In Example 2, the corresponding slurry is mud, and the solid-liquid separation is carried out directly.

[0058] ginseng Figure 5 As shown, compared with the foregoing embodiments, the main difference is only that the peristaltic separator 100 described in this embodiment is not provided with a vacuum tank structure. In the absence of a vacuum tank, there is generally no need to specifically collect gaseous substances.

[0059] Other structural parts are similar to the foregoing embodiments. After passing through the peristaltic separator 100 , the moisture in the mud will flow out from the discharge pipe 420 , and the slag will be discharged from the discharge port 510 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com