Large-breadth jointless splicing precise laser drilling device

A technology of seamless splicing and laser drilling, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of many process parameters, immature process, short design cycle, etc., and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

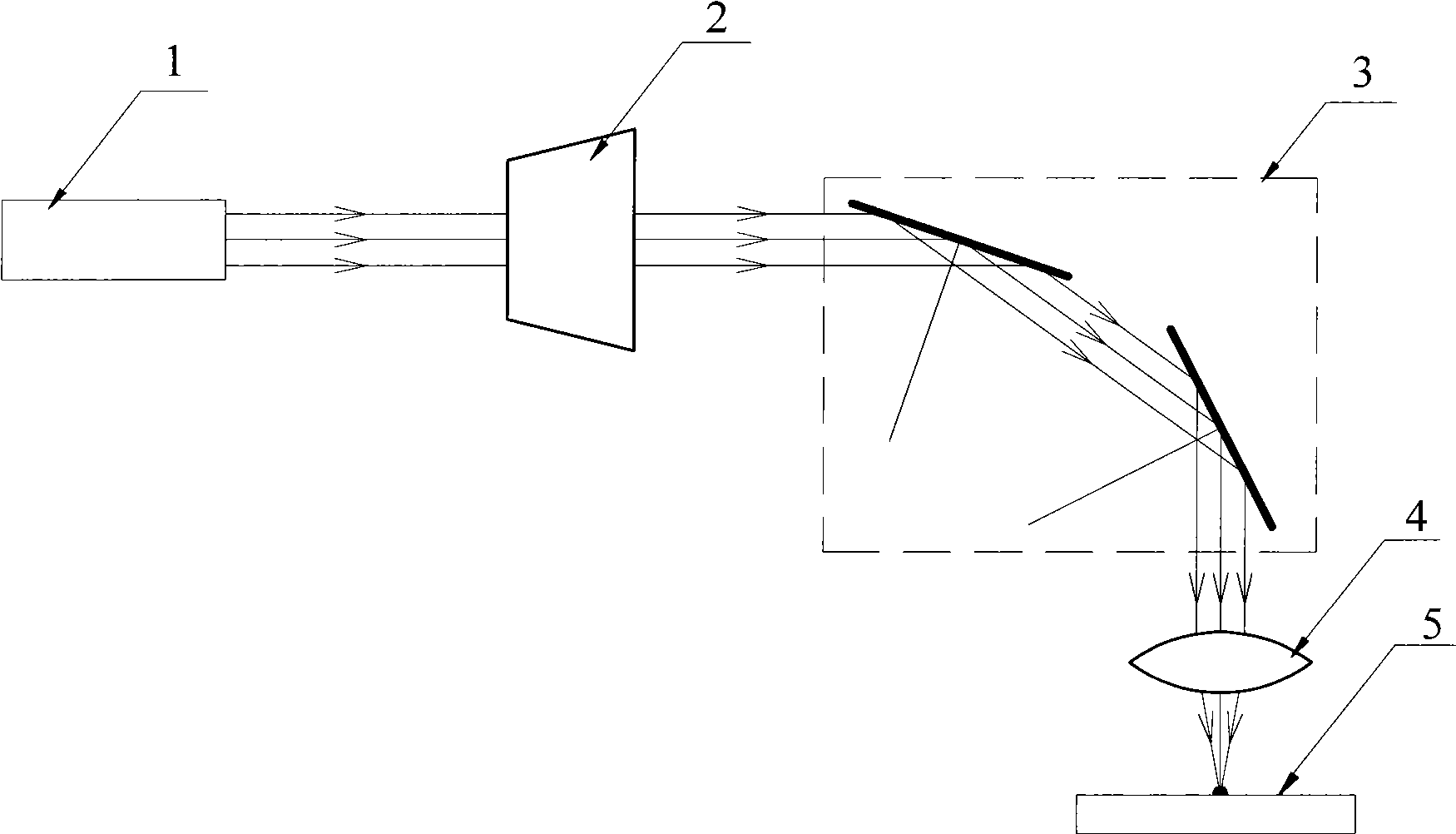

[0018] Laser drilling belongs to the category of material removal processing. Using the characteristics of high laser power density to focus it, the processed material is heated, melted and vaporized instantly, and the molten material is expelled by the residual pressure of the steam to form holes. That is to use the spot shape of the laser to repeatedly drill holes at the same position. The light from the laser is expanded and shaped into parallel light (to facilitate finer focusing), and then rotates the mirror in two directions to form a plane scan. Then focus on the focal plane (the surface of the workpiece) through an appropriate focusing lens. Where there is a pattern, the laser Q switch is turned on to perform light drilling at a high frequency (20KHz) repetition rate.

[0019] like figure 1 As shown, the large-format seamless splicing precision laser drilling device includes a laser 1, a beam expander 2, a vibrating mirror 3 and a focusing mirror 4. The output end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Laser power | aaaaa | aaaaa |

| Beam diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com