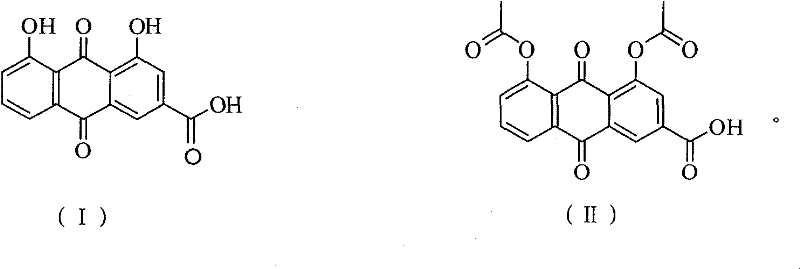

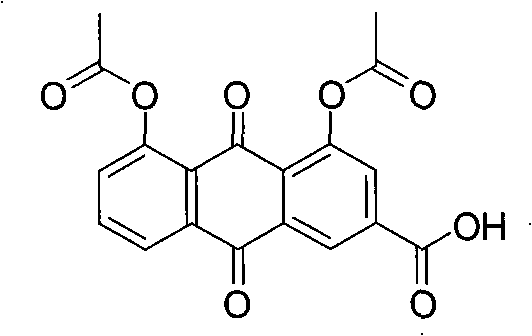

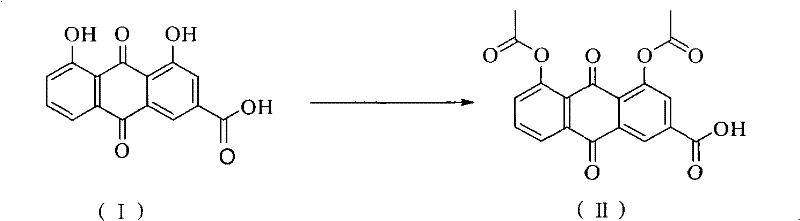

Method of preparing diacetyl rhein

A technology of diacetylrhein and rhein, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of high production costs, and achieve low production costs, easy access to raw materials, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Rhein (5.64g, 20mmol), zinc trifluoromethanesulfonate (0.04g, 0.1mmol) and acetic anhydride (12.25g, 120mmol) were put into a 100ml reaction vessel, and heated to 138°C for 1h under stirring. After the reaction, the temperature of the reaction solution was lowered to room temperature, and a solid was precipitated, filtered, and the filter cake was recrystallized with acetic acid, and dried to obtain diacetylrhein (7.05 g). The HPLC purity was 99.5%, and the yield was 95.2%.

Embodiment 2

[0025] Put rhein (5.64g, 20mmol), zinc trifluoromethanesulfonate (0.04g, 0.1mmol) and acetic anhydride (12.25g, 120mmol) into a 100ml reaction vessel, heat up to 138°C for 2h under stirring. After the reaction, the temperature of the reaction solution was lowered to room temperature, and a solid was precipitated, filtered, and the filter cake was recrystallized with acetic acid, and dried to obtain diacetylrhein (7.14 g). The HPLC purity was 99.7%, and the yield was 96.6%.

Embodiment 3

[0027] Put rhein (5.64g, 20mmol), zinc trifluoromethanesulfonate (0.04g, 0.1mmol) and acetic anhydride (8.17g, 40mmol) into a 50ml reaction vessel, heat up to 138°C for 0.5h under stirring . After the reaction, the temperature of the reaction solution was lowered to room temperature, and a solid was precipitated, filtered, and the filter cake was recrystallized with acetic acid, and dried to obtain diacetylrhein (7.10 g). The HPLC purity was 99.4%, and the yield was 95.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com