Biomass fuel cycle gasifying device and method thereof

A biomass fuel and gasification device technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of poor practicability, high toxicity, low gas calorific value, etc., and achieve the effect of improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

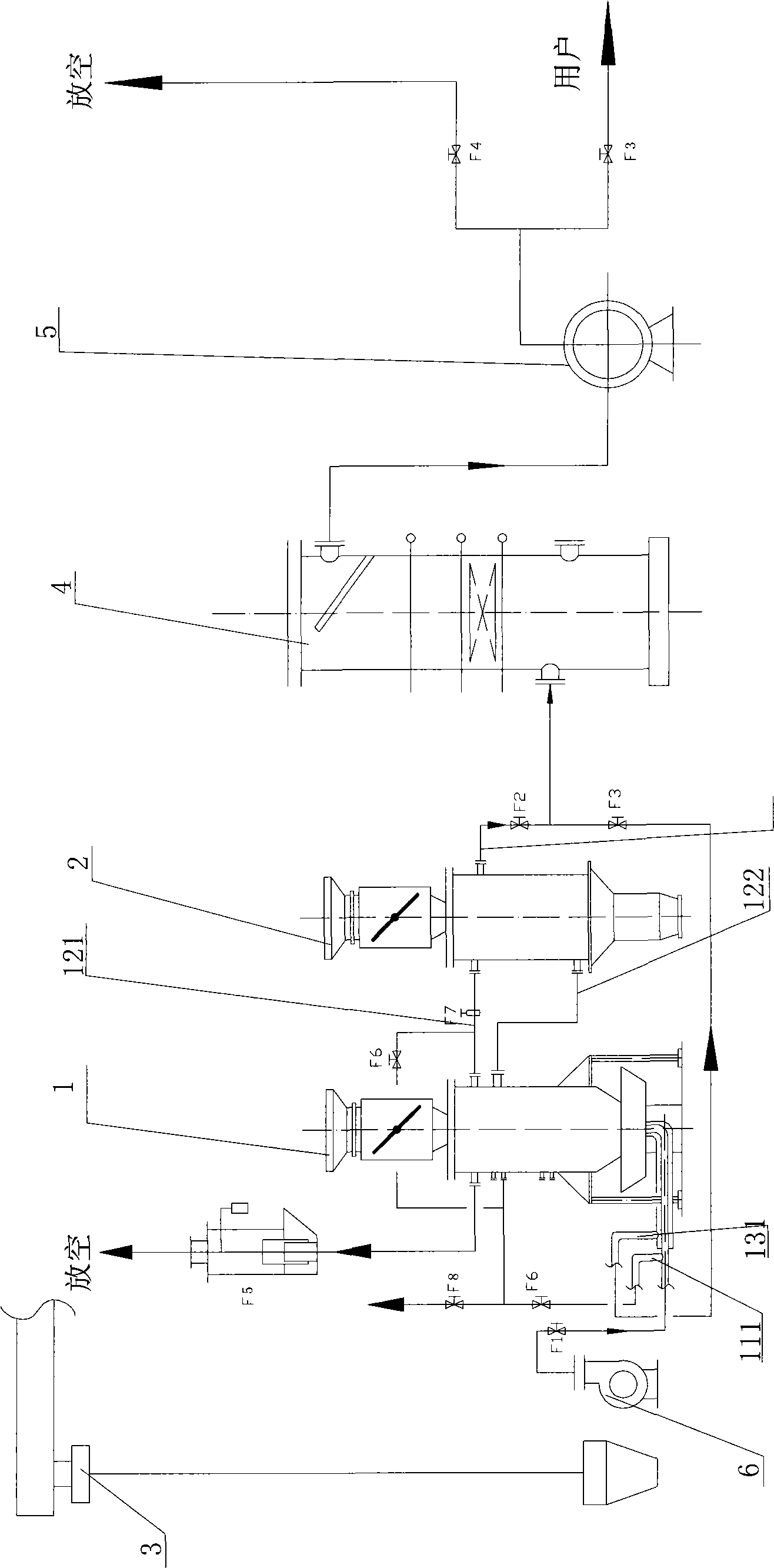

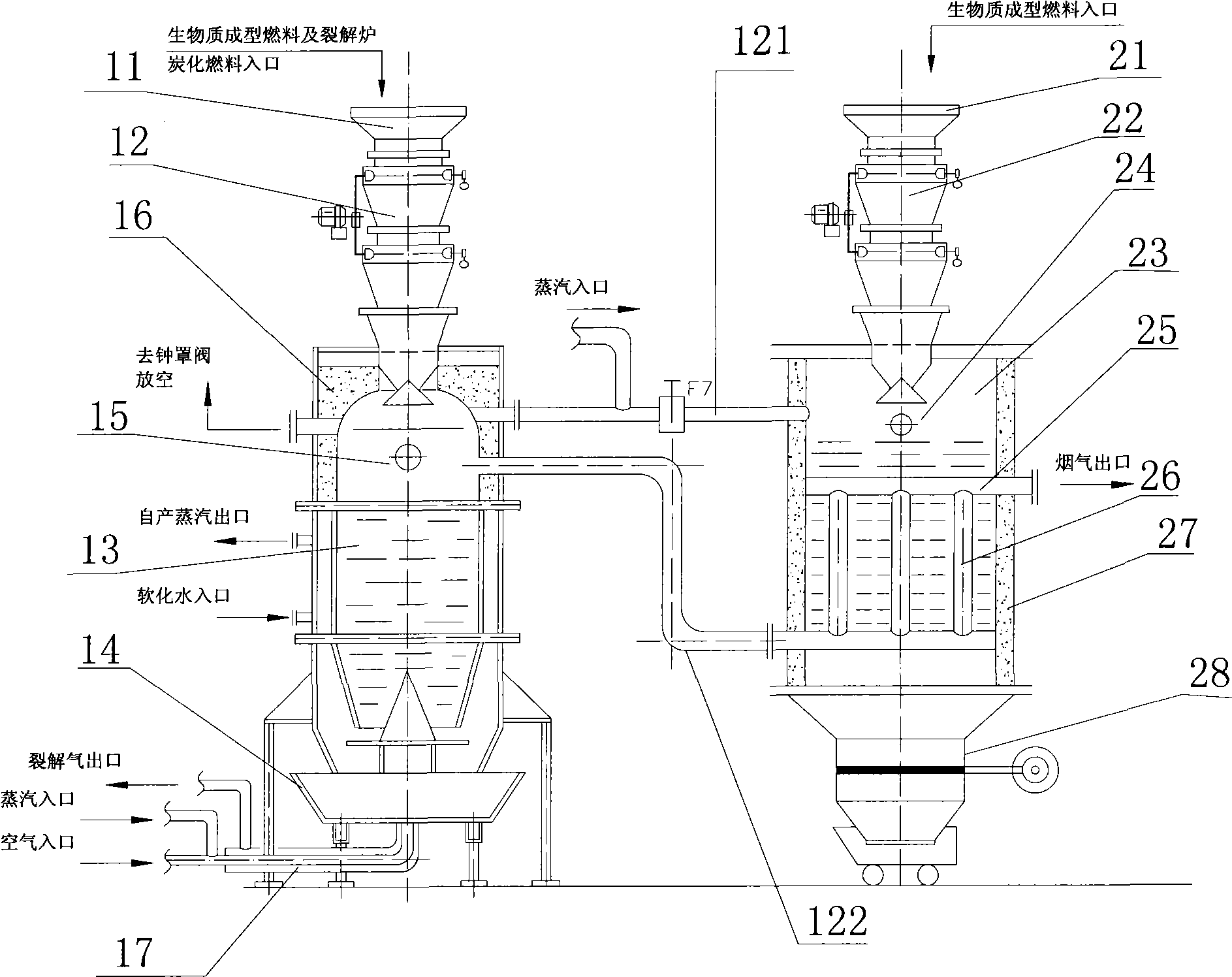

[0059] Embodiment: As shown in the figure, the biomass fuel cycle gasification device includes a track conveying system 3 controlled by an electric hoist, a gas purification device 4, an independently arranged combustion furnace 1 and a cracking furnace 2, and the upper ends of the combustion furnace and the cracking furnace are sealed. The feeding device of the cover, respectively seals the combustion furnace and the cracking furnace through the sealing cover of the feeding device.

[0060] A layer of refractory material is built on the outer side of the upper part of the combustion furnace body, and is communicated with the heating part 25 and the carbonization part 23 of the cracking furnace through the flue gas delivery pipe 122 and the retort gas delivery pipe 121; a water jacket 13 is arranged outside the middle layer of the combustion furnace body; The steam delivery pipe 111 controlled by the self-produced steam electric steam inlet valve F6 is arranged on the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com