Fe-based amorphous alloy material and method of producing the same

A technology of iron-based amorphous alloy and magnetic material, which is applied in the field of iron-based amorphous alloy magnetic material and its preparation, and achieves the effects of simple process, strong glass forming ability and excellent soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

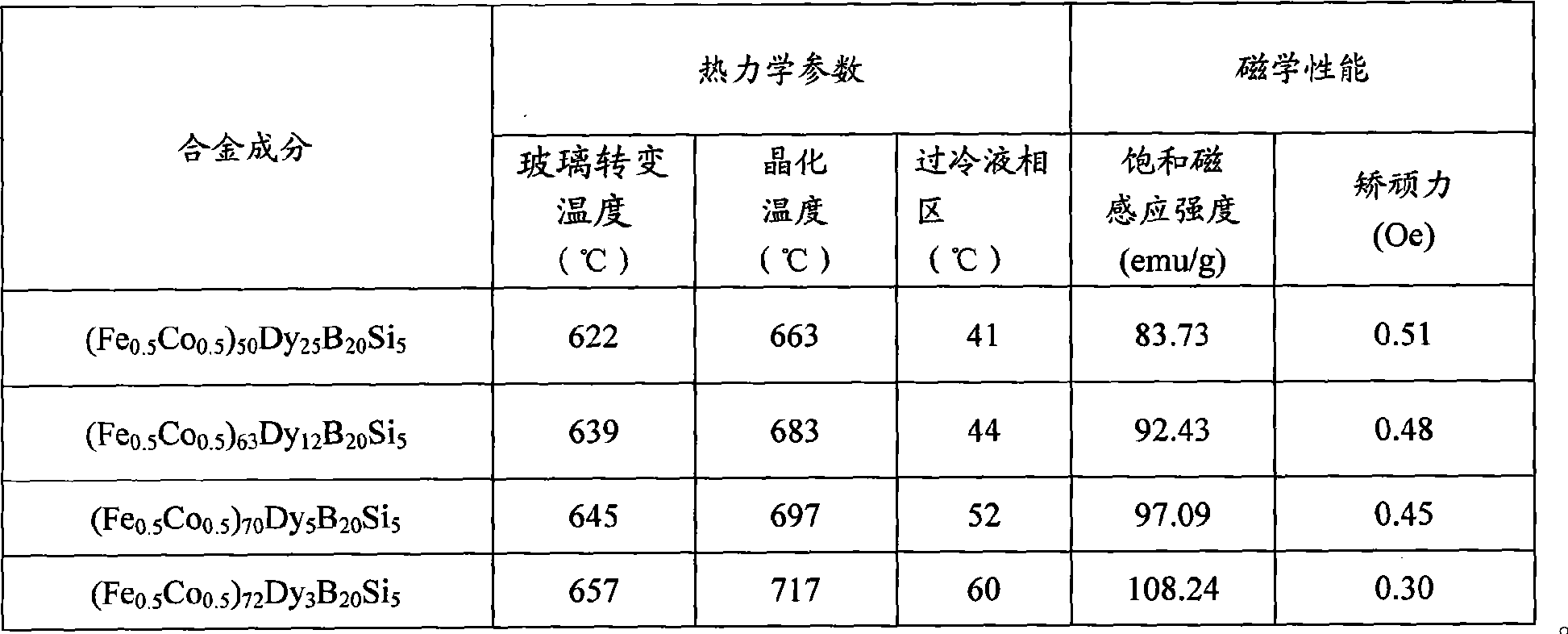

Examples

Embodiment 1

[0016] Embodiment 1: preparation (Fe 0.5 co 0.5 ) 50 Dy 25 B 20 Si 5 Amorphous Alloy Ribbon

[0017] This embodiment adopts the single-roller stripping method to prepare a thickness of 40 μm-80 μm, a width of 2.0mm-2.5mm (Fe 0.5 co 0.5 ) 50 Dy 25 B 20 Si 5 Amorphous alloy thin strips.

[0018] Step 1: By atomic percentage (Fe 0.5 co 0.5 ) 50 Dy 25 B 20 Si 5 Weigh Fe with a purity of 99.8%, Co with a purity of 99.9%, Si with a purity of 99.9%, Dy and FeB alloys with a purity of 99.9%, and put the weighed target composition raw materials into a vacuum high-frequency induction melting furnace, Vacuum down to 4×10 -3 Pa, filled with high-purity argon protective gas, adjusted the current to 35A, and repeatedly smelted the alloy for 5 times to obtain a uniform composition (Fe 0.5 co 0.5 ) 50 Dy 25 B 20 Si 5 master alloy.

[0019] Step 2: Take the (Fe 0.5 co 0.5 ) 50 Dy 25 B 20 Si 5 The master alloy ingot is broken into small pieces after descaling, and...

Embodiment 2

[0023] Embodiment 2: preparation (Fe 0.5 co 0.5 ) 63 Dy 12 B 20 Si 5 Amorphous Alloy Ribbon

[0024] This embodiment adopts the single-roller stripping method to prepare a thickness of 40 μm-80 μm, a width of 2.0mm-2.5mm (Fe 0.5 co 0.5 ) 63 Dy 12 B 20 Si 5 Amorphous alloy thin strips.

[0025] Step 1: By atomic percentage (Fe 0.5 co 0.5 ) 63 Dy 12 B 20 Si 5 Weigh Fe with a purity of 99.8%, Co with a purity of 99.9%, Si with a purity of 99.9%, Dy and FeB alloys with a purity of 99.9%, and put the weighed target composition raw materials into a vacuum high-frequency induction melting furnace, Vacuum down to 4×10 -3 Pa, filled with high-purity argon protective gas, adjusted the current 20A, and repeatedly smelted the alloy 5 times to obtain a uniform composition (Fe 0.5 co 0.5 ) 63 Dy 12 B 20 Si 5 master alloy.

[0026] Step 2: Take the (Fe 0.5 co 0.5 ) 63 Dy 12 B 20 Si 5 The master alloy ingot is broken into small pieces after descaling, and ultras...

Embodiment 3

[0030] Embodiment 3: preparation (Fe 0.5 co 0.5 ) 70 Dy 5 B 20 Si 5 Amorphous Alloy Ribbon

[0031] This embodiment adopts the single-roller stripping method to prepare a thickness of 40 μm-80 μm, a width of 2.0mm-2.5mm (Fe 0.5 co 0.5 ) 70 Dy 5 B 20 Si 5 Amorphous alloy thin strips.

[0032] Step 1: By atomic percentage (Fe 0.5 co 0.5 ) 70 Dy 5 B 20 Si 5 Weigh Fe with a purity of 99.8%, Co with a purity of 99.9%, Si with a purity of 99.9%, Dy and FeB alloys with a purity of 99.9%, and put the weighed target composition raw materials into a vacuum high-frequency induction melting furnace, Vacuum to 3.8×10 -3 Pa, filled with high-purity argon protective gas, adjusted the current 27A, and repeatedly smelted the alloy for 7 times to obtain a uniform composition (Fe 0.5 co 0.5 ) 70 Dy 5 B 20 Si 5 master alloy.

[0033] Step 2: Take the (Fe 0.5 co 0.5 ) 70 Dy 5 B 20 Si 5 The master alloy ingot is broken into small pieces after descaling, and ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com