Method for intertexture production of high-moisture absorption ultra-soft towel with Modal and cotton

A high moisture absorption and super soft technology, applied in the direction of fabrics, textiles, bleached products, etc., can solve the problems of easy hardening and low hygroscopicity, and achieve the effect of soft hand feeling, less fiber damage and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

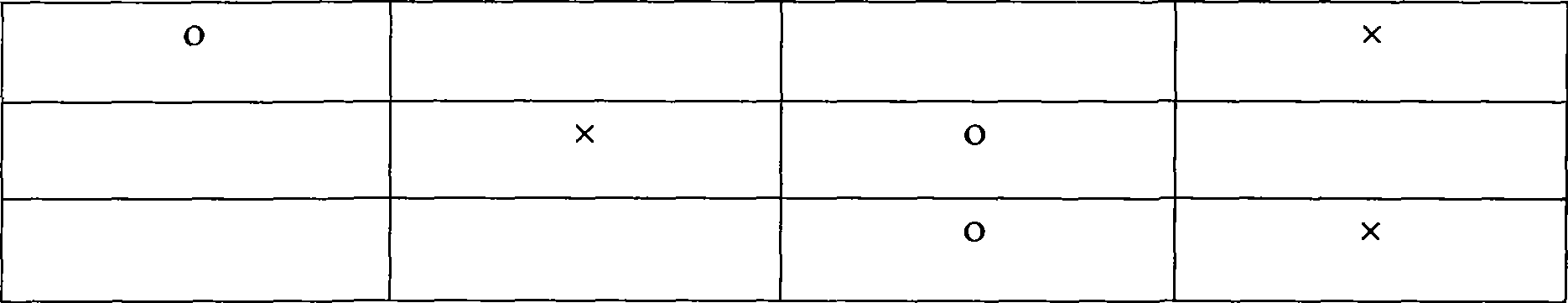

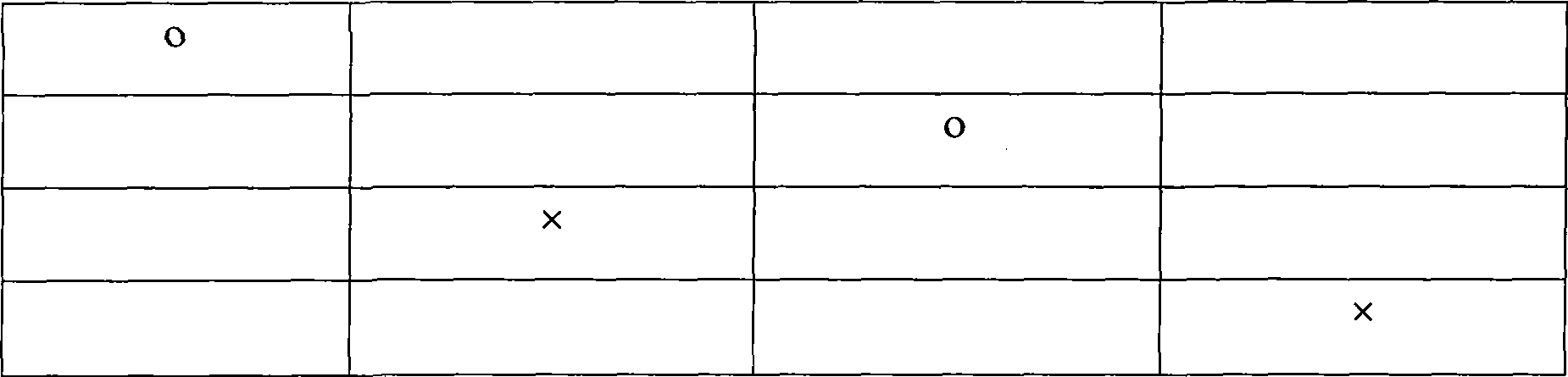

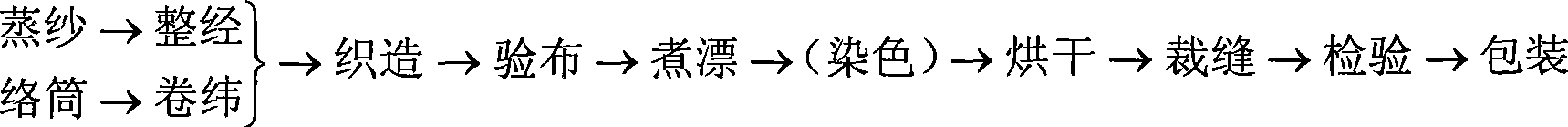

[0020] The Modal and cotton interwoven towel yarn is processed by steaming machine, and the Modal fiber of 16.8tex×2 is selected as the towel warp (upper warp) yarn; the cotton fiber yarn of 26.2tex×2 is selected as the bottom warp; the cotton fiber yarn of 26.2tex is selected As a weft, prepare towelettes.

[0021] Add osmotic agent JFC5g / L at room temperature, adjust the pH value to 7→immerse in a towel→raise the temperature to 50°C, add 25g / L compound enzyme, keep warm for 60min→raise the temperature to 95°C, add 30% H 2 o 2 15g / L, Na 2 SiO 3 5g / L insulation for 45min.

Embodiment 2

[0023] Modal and cotton interwoven towel yarn are processed by steaming machine, and Modal fiber of 18tex×2 is selected as towel warp (upper warp) yarn; cotton fiber yarn of 28.2tex×2 is selected as lower warp; cotton fiber yarn of 28.2tex is selected as Weft yarn to prepare bath towels.

[0024] Add osmotic agent JFC 5g / L at room temperature, adjust the pH value to 7→immerse in a towel→raise the temperature to 55°C, add 20g / L compound enzyme, keep warm for 55min→raise the temperature to 98°C, add 30% H 2 o 2 20g / L, Na 2 SiO 3 5g / L insulation for 45min.

Embodiment 3

[0026] The Modal and cotton interwoven towel yarn is processed by steaming machine, and the Modal fiber of 22.5tex×2 is selected as the towel warp (top warp) yarn; the cotton fiber yarn of 32tex×2 is used as the bottom warp; the cotton fiber yarn of 32tex is selected as the weft yarn , to produce towel blankets.

[0027] Add osmotic agent JFC5.5g / L at room temperature, adjust the pH value to 7→immerse in a towel→heat up to 55°C, add compound enzyme 20g / L, keep warm for 60min→raise temperature to 98°C, add 30% H 2 o 2 20g / L, Na 2 SiO 3 5g / L insulation for 60min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com