Hydraulic ABS test stand based on wheel speed closed-loop simulation

A test bench, hydraulic technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as the inability to detect ABS quickly, effectively and economically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

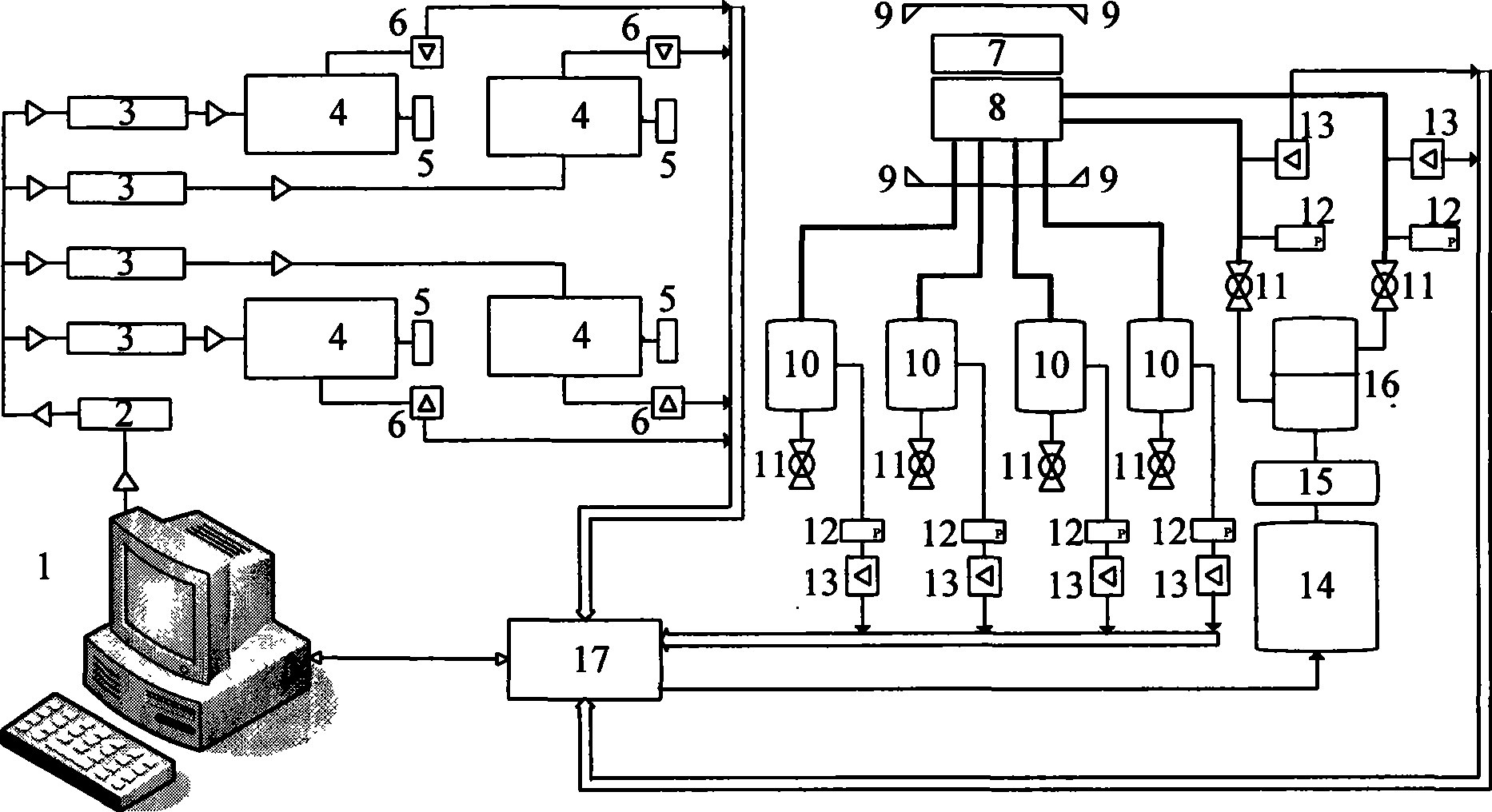

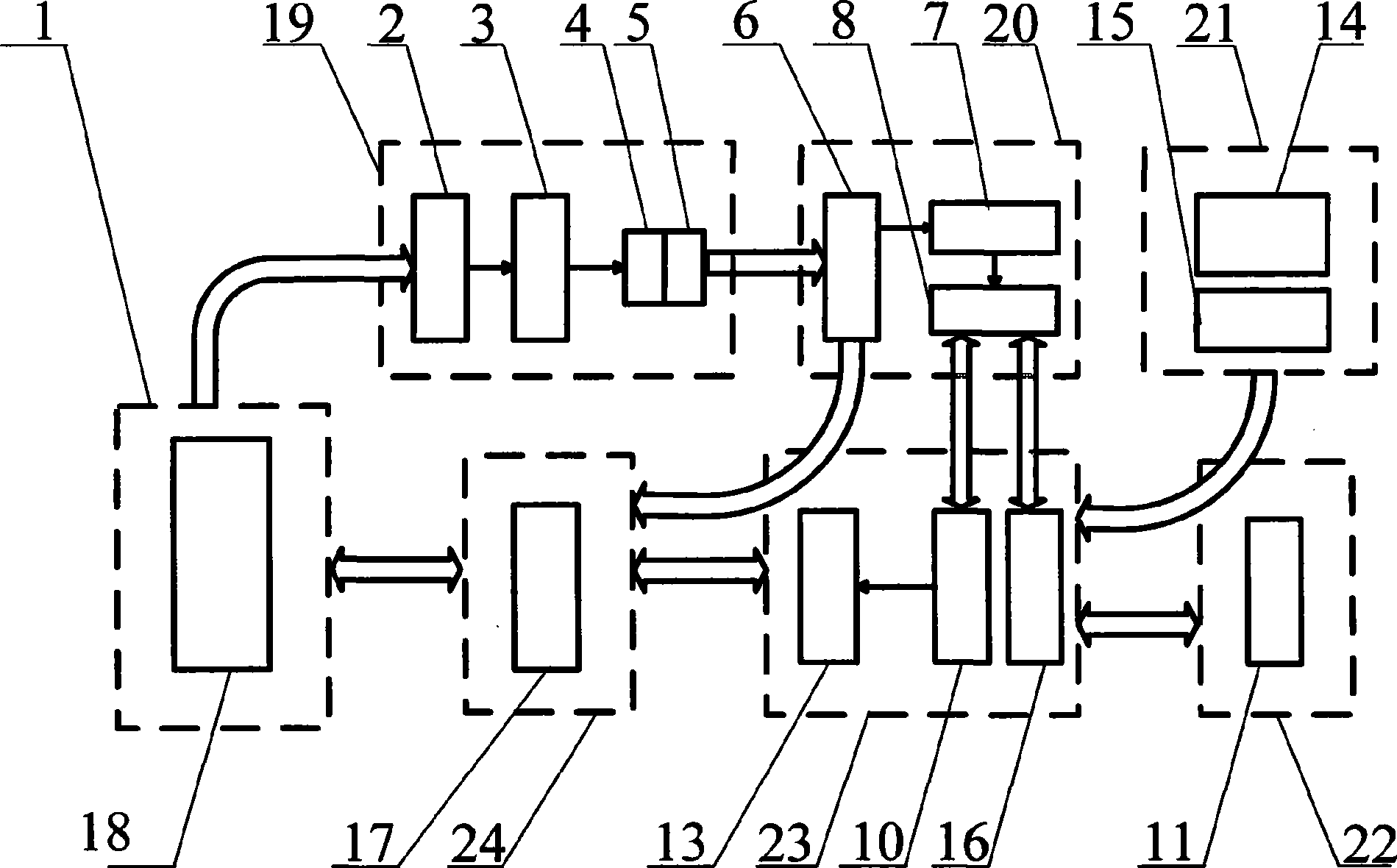

[0010] This test bench is mainly composed of industrial computer (1), wheel speed generating device (19), system under test (20), pressure source (21), deflation system (22), braking system (23) and data acquisition system ( 24) Composition.

[0011] Below is that the present invention is further described in conjunction with accompanying drawing:

[0012] refer to figure 1 , the industrial computer (1) is connected to the motion controller (2) through the PCI slot, the motion controller (2) is connected to the AC servo motor driver (3) through the adapter plug, and the AC servo motor driver (3) is connected to the AC servo motor (4) Connected via 220V power line and signal line; the ring gear (5) is fixed on the shaft of the AC servo motor (4), and the wheel speed sensor (6) and the ring gear (5) are fixed on the AC servo motor ( 4) on; thus the industrial computer (1) can control the operation of the AC servo motor (4).

[0013] The tested system (20) includes ABS ECU (El...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com