Wave wafer, manufacturing method, mold and liquid crystal panel

A manufacturing method and wave chip technology, which are applied in optics, instruments, nonlinear optics, etc., can solve the problems of increased cost, increased light loss, discomfort, etc., and achieve the advantages of being easy to use and carry, reducing visual fatigue, and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

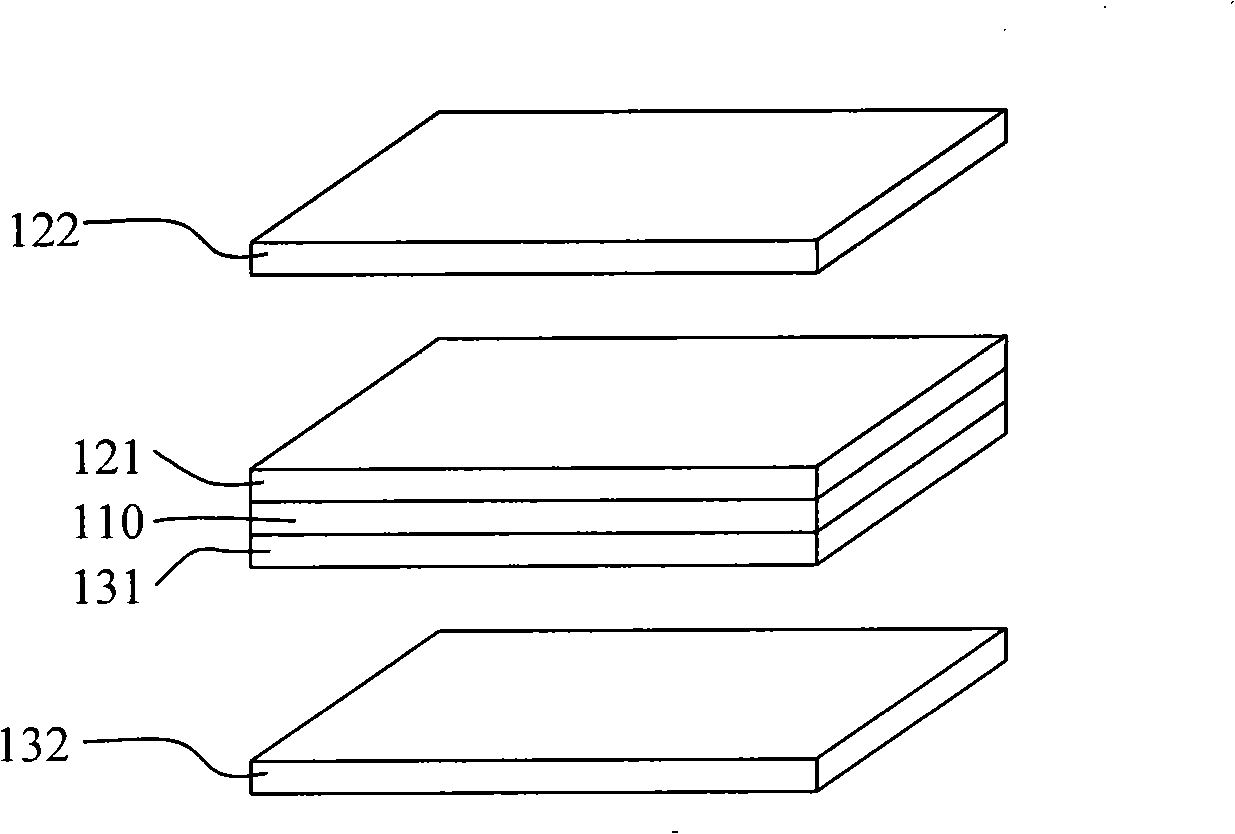

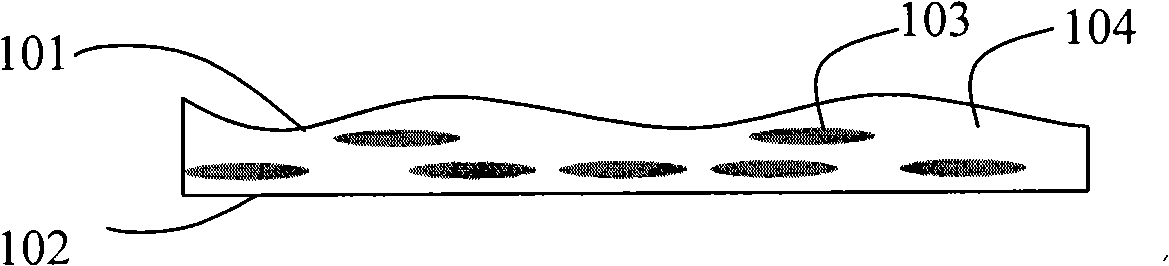

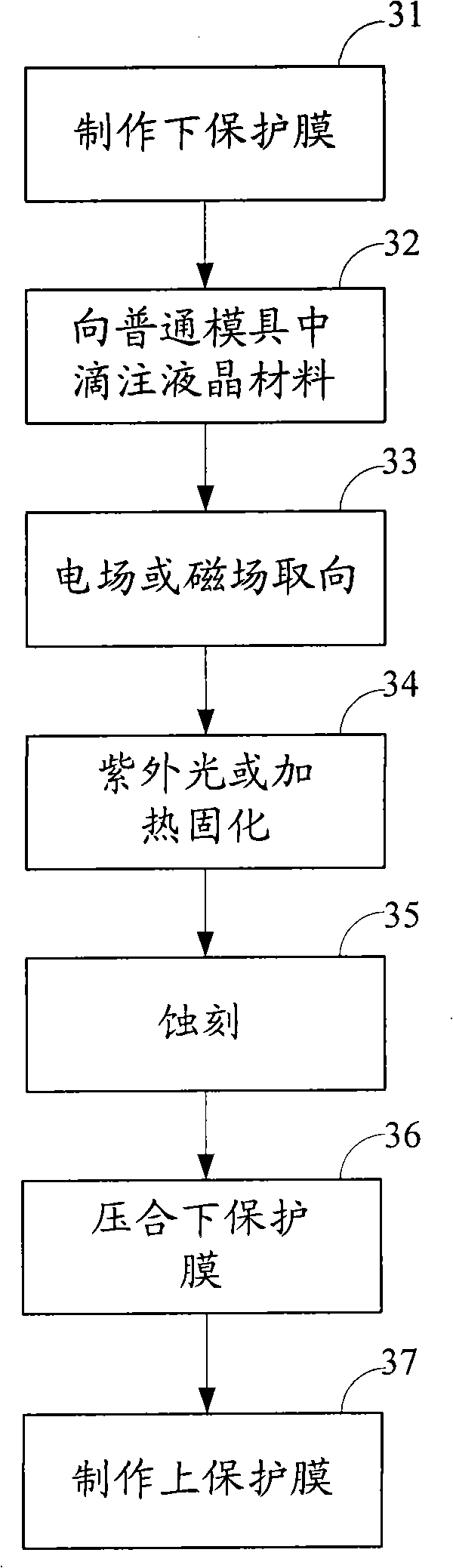

[0052] The present invention is aimed at broadband wavelength light design, and the wave chip is designed as a shape of thickness change, and the minimum thickness and maximum thickness are respectively designed according to the minimum and maximum light wavelengths of broadband wavelength light, so that the minimum light wavelength is transmitted through the minimum thickness of the wave chip. The phase difference of e light and the phase difference of o light and e light at the place where the maximum light wavelength passes through the maximum thickness are both Odd multiples of , so that there is a corresponding position for any wavelength of light so that the phase difference is Odd multiples, the outgoing light changes from linearly polarized li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com