Polymer agitating device

A stirring device and polymer technology, which is applied to mixers with rotating stirring devices, mixers, dissolving, etc., can solve the problems of reducing the volume of the aging tank, occupying a large space for equipment, and small available space for the platform, so as to improve the stirring effect , Compact structure, the effect of reducing the volume of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the embodiments.

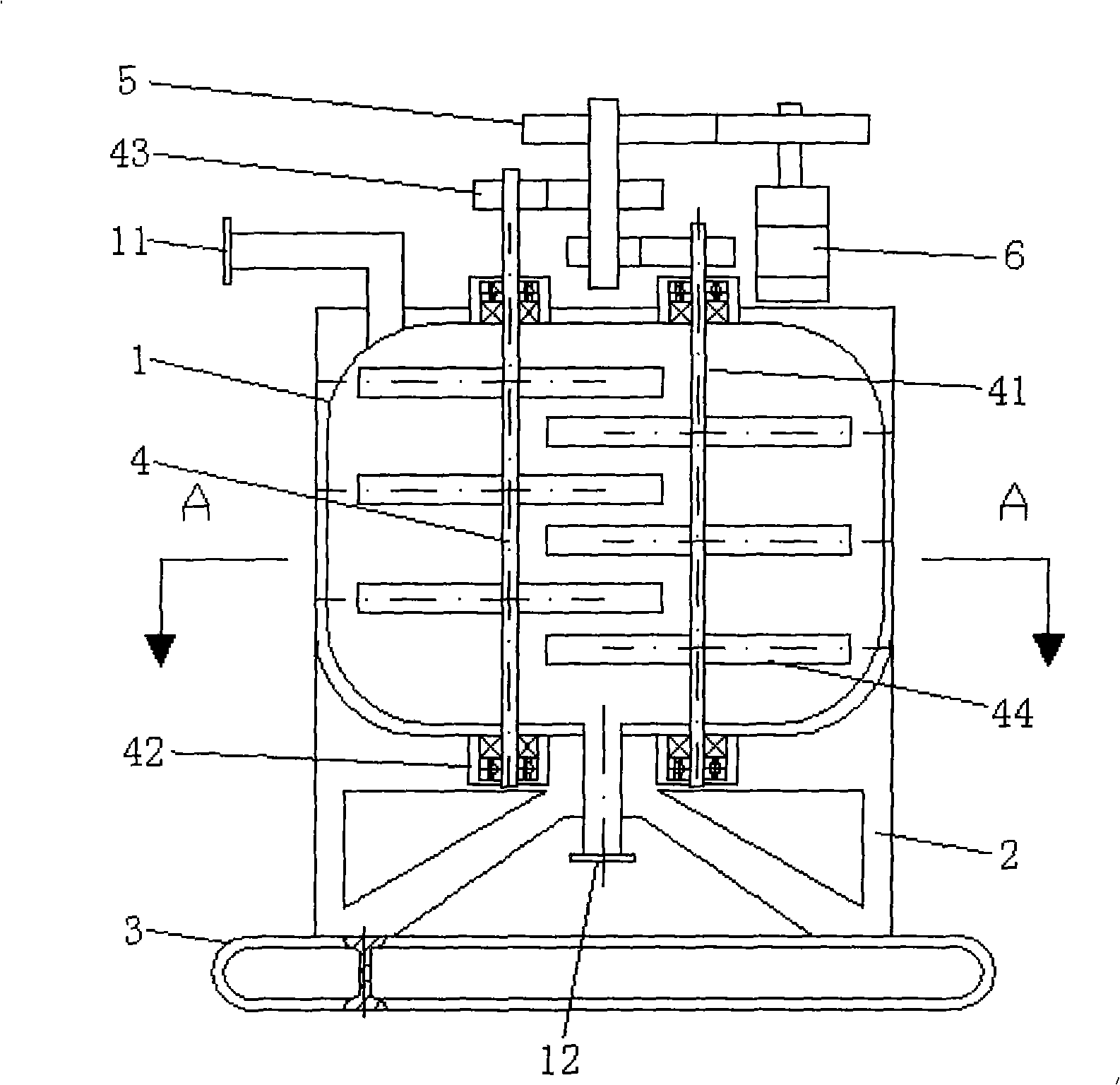

[0010] Such as figure 1 , figure 2 As shown, the present invention includes a stirring tank 1, a cylindrical support 2 and a base 3, the stirring tank 1 is vertically fixedly arranged in the support 2, and the support 2 is then fixedly arranged on the base 3.

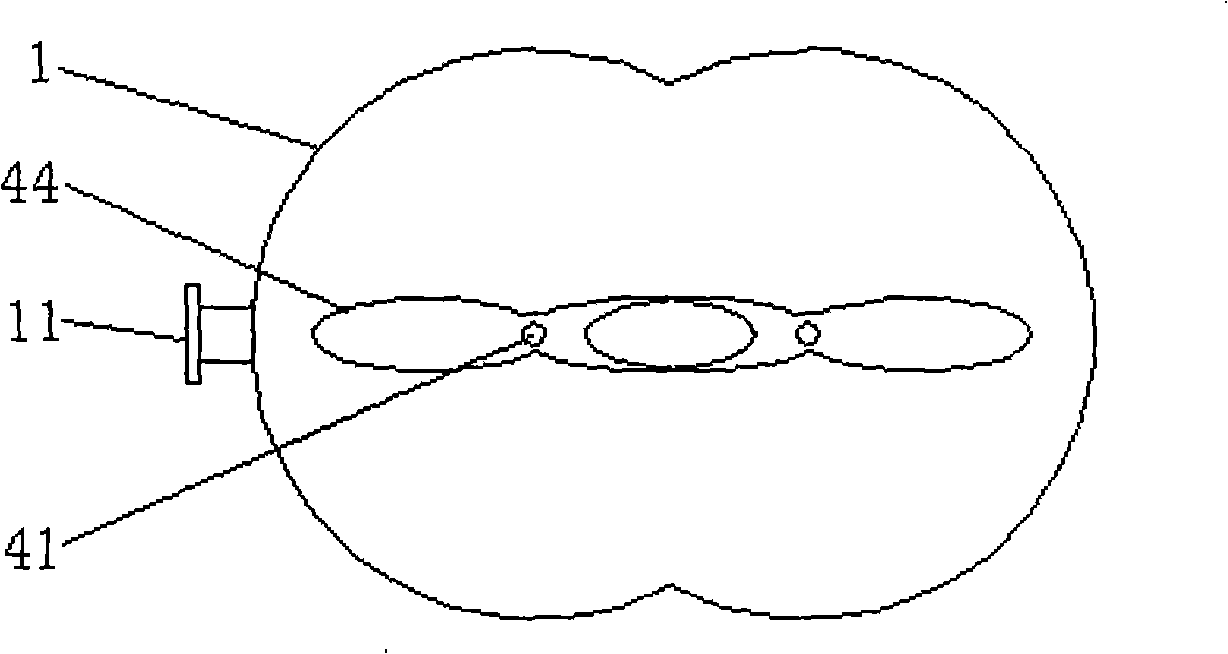

[0011] The section of the mixing tank 1 is 8-shaped, and a feed inlet 11 is arranged on the upper part, and a discharge outlet 12 is arranged on the bottom. A biaxial agitator 4 is arranged axially in the mixing tank 1, and the biaxial agitating device 4 includes two main shafts 41 axially penetrating the mixing tank 1, and the upper and lower ends of the two main shafts 41 are respectively fixed to the mixing tank 1 through axial bearings 42. Meanwhile, the upper ends of the two main shafts 41 are respectively provided with a gear 43, and the two gears 43 are connected with a gear transmission 5, and the gear transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com