Piezoelectric/electrorheological mixed ultraprecise hydraulic step drive device

A stepping drive, electrorheological technology, applied in the direction of fluid pressure actuating devices, valve devices, engine components, etc., can solve problems such as restricting development, inability to meet higher-precision use requirements, and small output driving force. The effect of long life, large output load and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

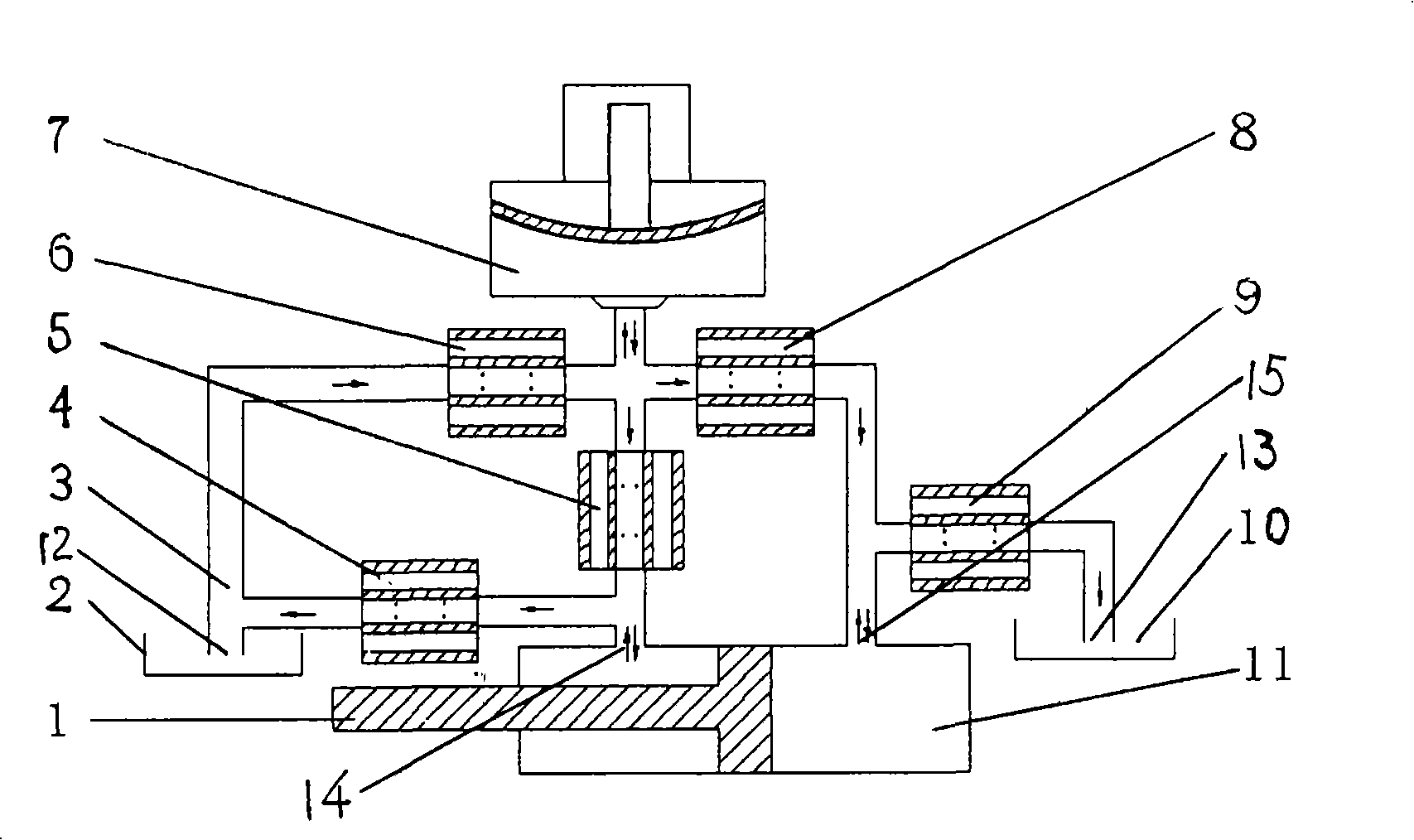

[0017] Pipeline 3 is fixedly connected to electrorheological valve one 4, electrorheological valve two 5, electrorheological valve three 6, electrorheological valve four 8 and electrorheological valve five 9, and the inlet and outlet of the valveless piezoelectric stack pump 7 of the driving source are the same , and be connected with the pipeline, the outlet one 12 of the pipeline is connected with the container one 2, the outlet two 13 of the pipeline is connected with the container two 10, the piston rod 1 is housed in the precision hydraulic cylinder 11, and the input and output pipeline of one side of the precision hydraulic cylinder is connected with the pipeline The outlet three 14 located between the first electrorheological valve 4 and the second electrorheological valve 5 is connected, and the input and output pipeline on the other side of the precision hydraulic cylinder is connected with the outlet four 15 on the pipeline.

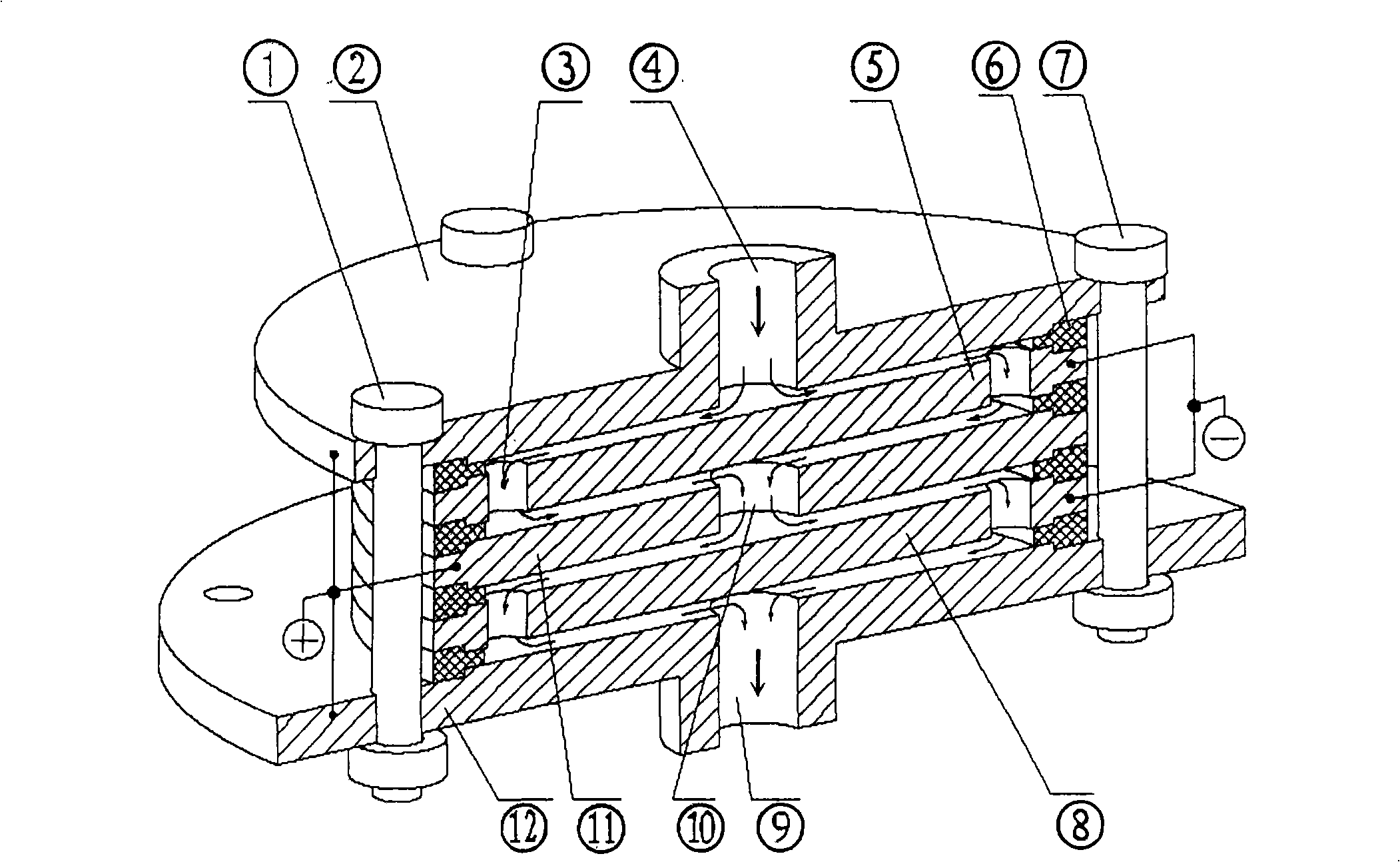

[0018] The electro-rheological valve adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com