Inner defect detector for annular workpiece

A ring-shaped workpiece and internal defect technology is applied in the field of ring-shaped workpiece internal defect detectors to achieve the effects of improving detection efficiency and safety, high degree of detection automation, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

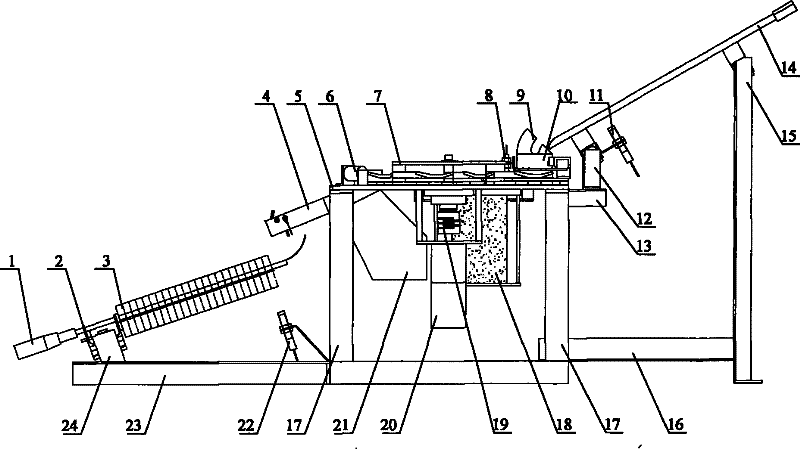

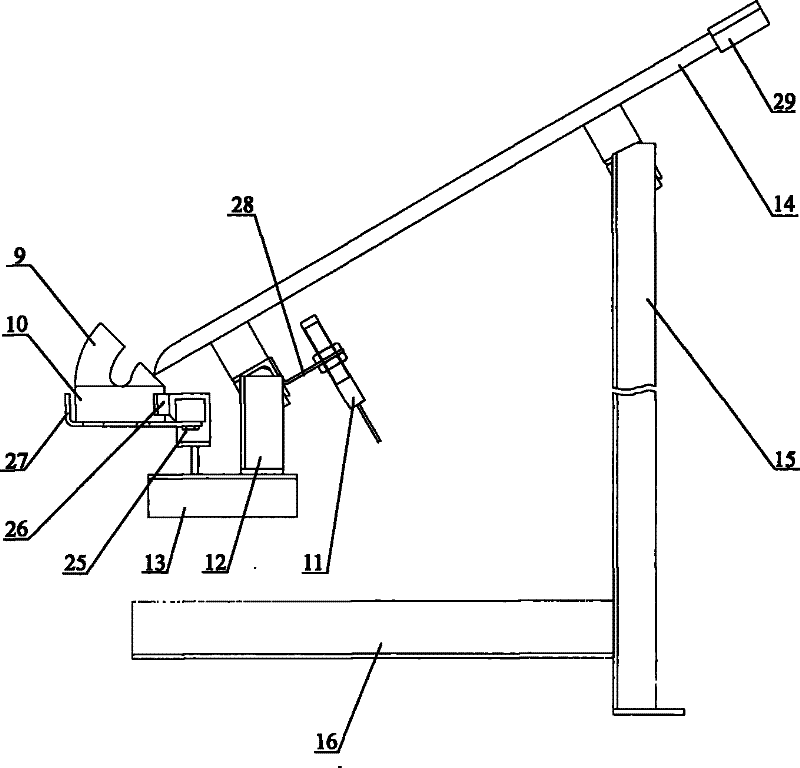

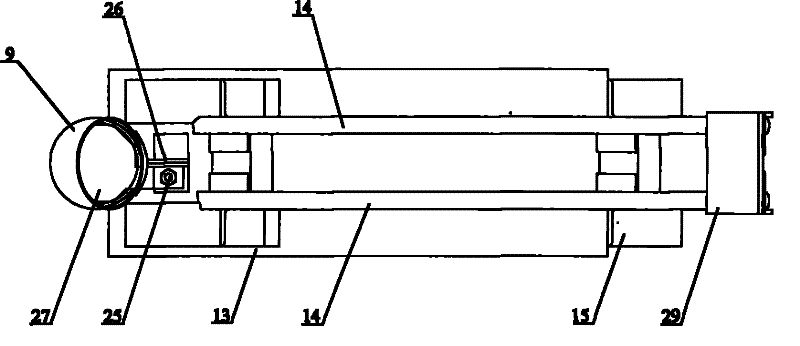

[0038] After the detection starts, place the ring-shaped workpiece 3 to be tested on two guide rail frames 14, make the ring-shaped workpiece 3 slide down and stagnate in the positioning ring 10, and the photoelectric switch 11 of the feeding unit counts the number of the sliding ring-shaped workpiece 3, and sends the signal Pass to the microprocessor, push away the flashboard 27 around the flashboard shaft 25, the annular workpiece 3 falls on the annular workpiece support plate 36, and the photoelectric switch 8 on the annular workpiece support plate 36 counts the annular workpiece 3 dropped; Start the DC motor 20, and the DC motor 20 drives the dial 7 to rotate. At the same time, each group of upper levers 32 and lower levers 35 sequentially push the ring workpiece 3 to drop from the ring workpiece support plate 36 to the excitation plate 41 to generate a sound signal, and the microphone 43 The sound signal is collected, amplified and encoded, and then sent to the DSP process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com