Method for manufacturing LED chips

A technology for light-emitting diodes and manufacturing methods, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as large differences in refractive index and inability to export chips, and achieve the effects of reducing interface reflection, reducing internal absorption, and improving defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

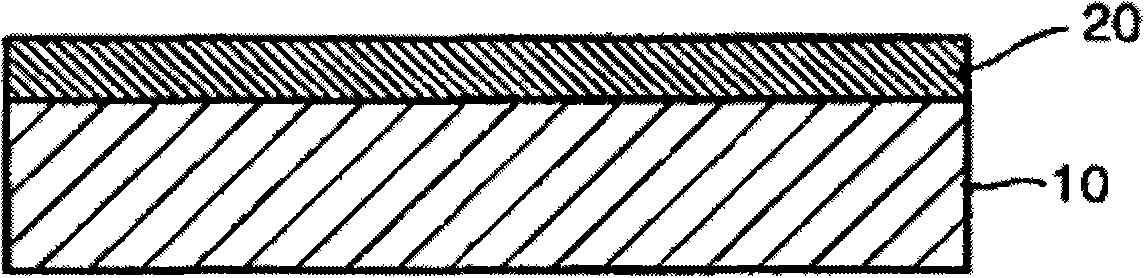

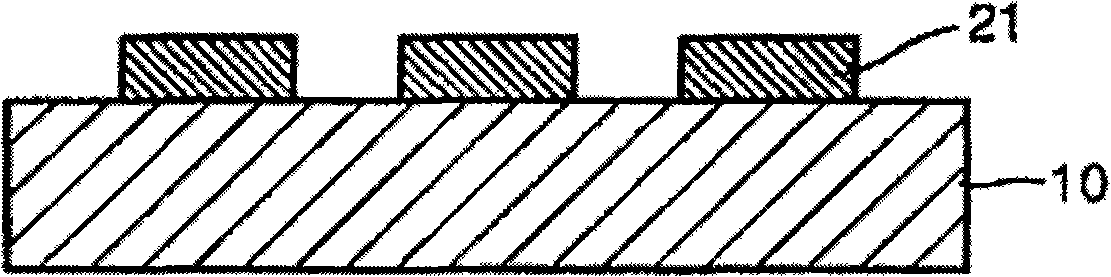

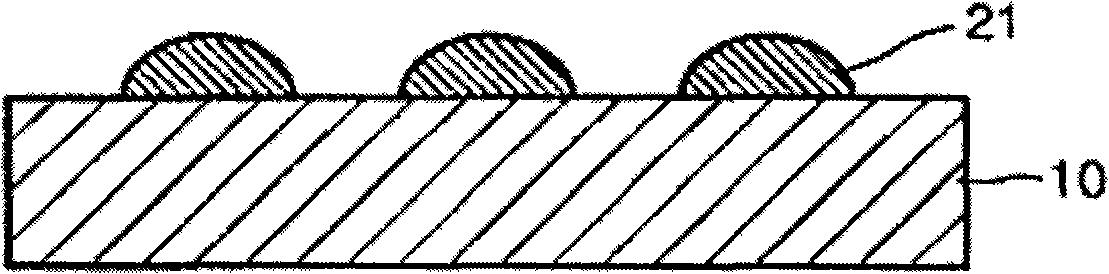

[0029] First refer to Figure 1a As shown, a photoresist is coated on the sapphire substrate 10 to form a layer of photoresist film layer 20. The thickness of the photoresist film layer 20 is 0.5um, and the photoresist is patterned on the substrate by photolithography technology. , forming the desired pattern as Figure 1b As shown, the pattern is a periodic regular arrangement of cylinders. Then use the platform baking photoresist reflow technology to form the photoresist pattern similar to Figure 1c A plurality of convex-hull microstructure patterns 21 are shown. The reflux condition is as follows: the baking temperature is 50° C., and the baking time is 0.1 minute. This pattern was then transferred to sapphire using coupled plasma reactive ion etching as Figure 1d As shown, a plurality of convex hull-shaped microstructures 11 are formed on the surface of the sapphire substrate 10, and the front side of the microstructures 11 is in the shape of a yurt, and its cross-se...

Embodiment 2

[0032] refer to Figure 1a As shown, a photoresist is coated on the sapphire substrate 10 to form a photoresist film layer 20, the thickness of the photoresist film layer 20 is 2um, and the photoresist is patterned on the substrate by photolithography technology , forming the desired pattern as Figure 1b As shown, the pattern is pyramids arranged regularly and periodically. Then use the platform baking photoresist reflow technology to form the photoresist pattern similar to Figure 1c A plurality of convex-hull microstructure patterns 21 are shown. The reflow conditions are as follows: the baking temperature is 200° C., and the baking time is 20 minutes. This pattern was then transferred to sapphire using coupled plasma reactive ion etching as Figure 1d As shown, a plurality of convex hull-shaped microstructures 11 are formed on the surface of the sapphire substrate 10, and the front surface of the microstructures 11 is yurt-shaped, and the cross-section is arc-shaped. ...

Embodiment 3

[0035] refer to Figure 1a As shown, a photoresist is coated on the sapphire substrate 10 to form a photoresist film layer 20, the thickness of the photoresist film layer 20 is 4um, and the photoresist is patterned on the substrate by photolithography technology , forming the desired pattern as Figure 1b As shown, the pattern is periodically and regularly arranged prisms. Then use the platform baking photoresist reflow technology to form the photoresist pattern similar to Figure 1c A plurality of convex-hull microstructure patterns 21 are shown. The reflow conditions are as follows: the baking temperature is 400° C., and the baking time is 60 minutes. This pattern was then transferred to sapphire using coupled plasma reactive ion etching as Figure 1d As shown, a plurality of convex hull-shaped microstructures 11 are formed on the surface of the sapphire substrate 10, and the front surface of the microstructures 11 is yurt-shaped, and the cross-section is arc-shaped. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com