Deep water hydrocarbon transfer system

A technology of oil and gas mooring, which is applied in the direction of transportation and packaging, special-purpose vessels, ships, etc., and can solve problems such as fast and easy establishment of mechanical and hydraulic connections that have not been pointed out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

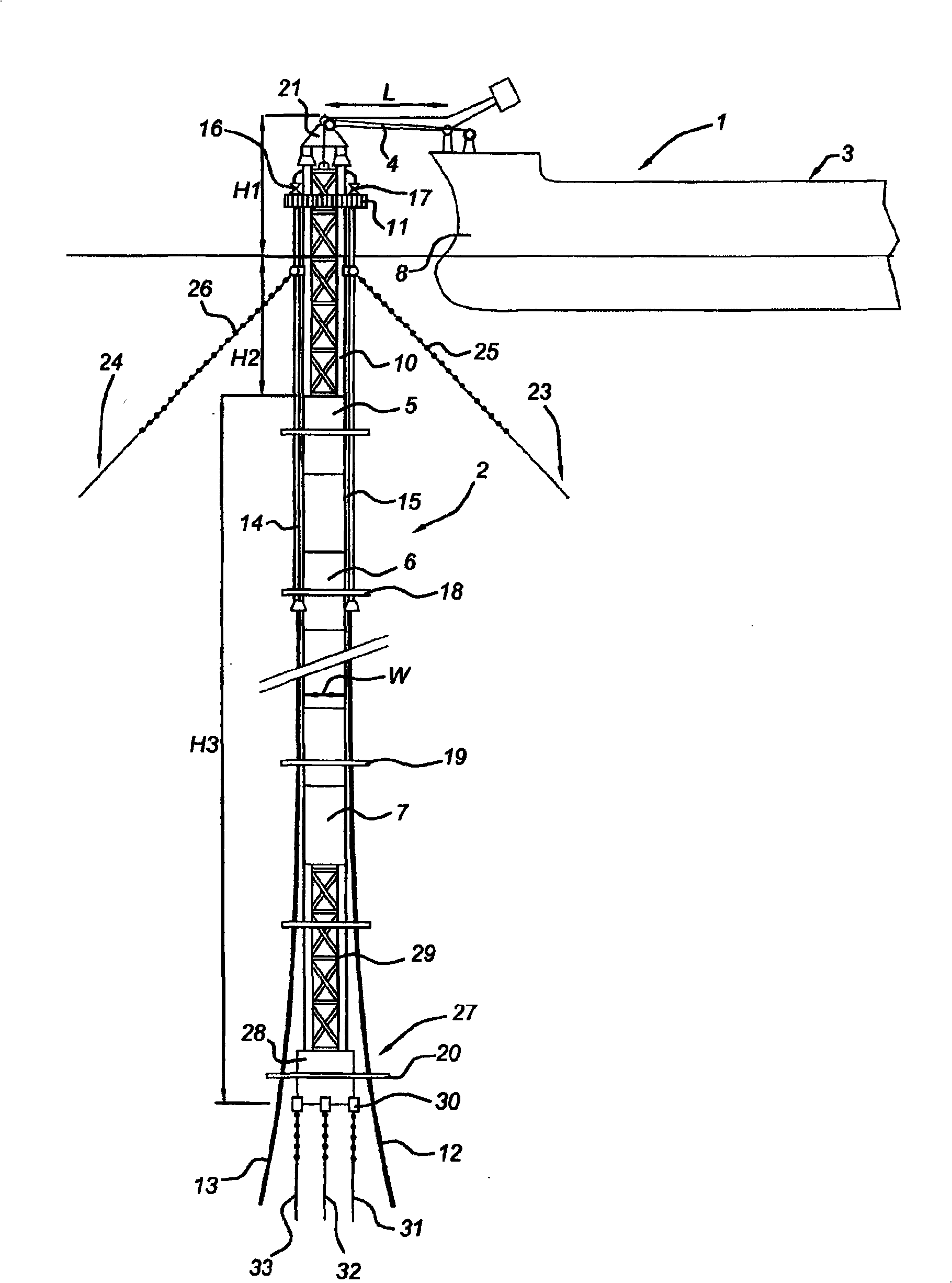

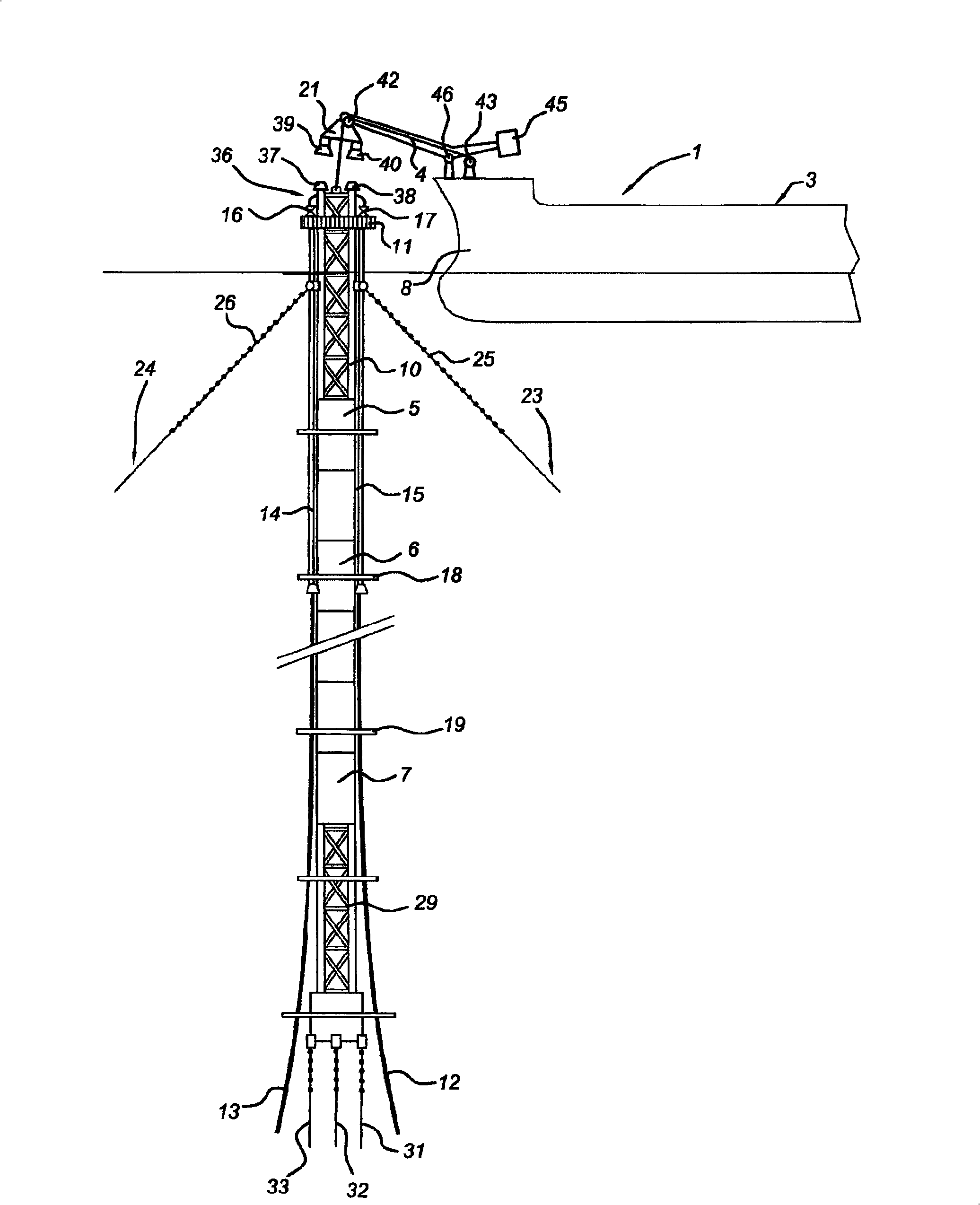

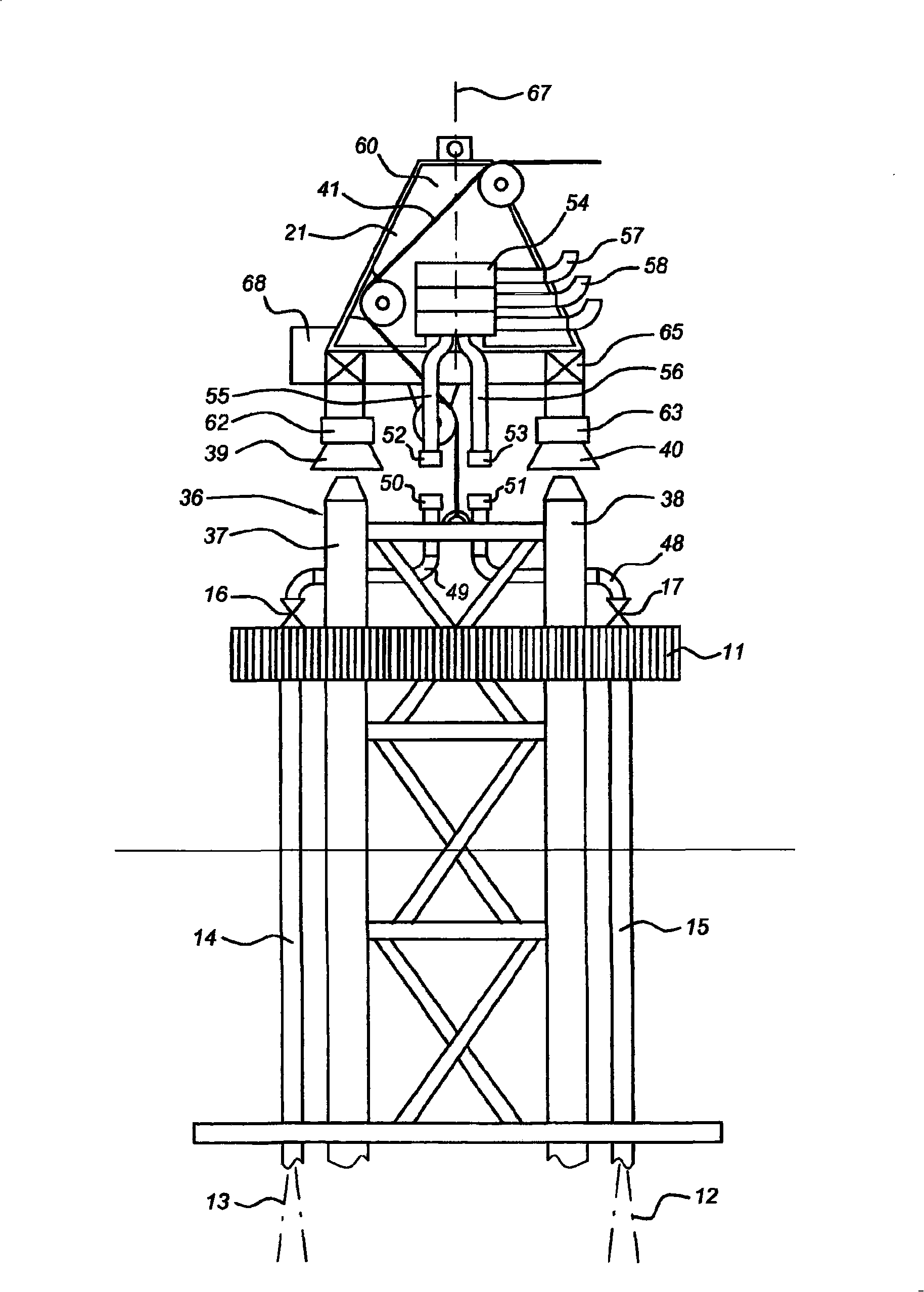

[0027] figure 1 An oil and gas transfer system 1 is shown comprising a mooring buoy 2 and a vessel 3 with a mooring arm 4 . The mooring buoy 2 comprises a plurality of subsea buoyancy members 5 , 6 , 7 and a truss support structure 10 carrying a support platform 11 . Steel risers 12 , 13 are guided from the subsea well to the support platform 11 . The upper half of the risers 12,13 are guided by riser ducts or "I-pipes" 14,15. The risers end in valves 16, 17 near the riser support platform 11, closing each riser. The arm 4 on the vessel 3 carries at its end a connector 21 for mechanical connection to the end of the upper buoy and for extending between the risers 12, 13 and via the connector 21 and the arm 4 to the vessel 3 Provide fluid connections between the pipelines.

[0028] The buoy 2 comprises lateral mooring lines 23, 24, each extending at an angle of approximately 45°, and attaching the buoy to the seabed. The lateral mooring lines limit the pitching and heaving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com